09 victor regulator – Tweco 201 ts Thermal Arc User Manual

Page 28

THERMAL ARC 161 STL, 201 TS

INSTALLATION

Installation 3-10

Manual 0-5203

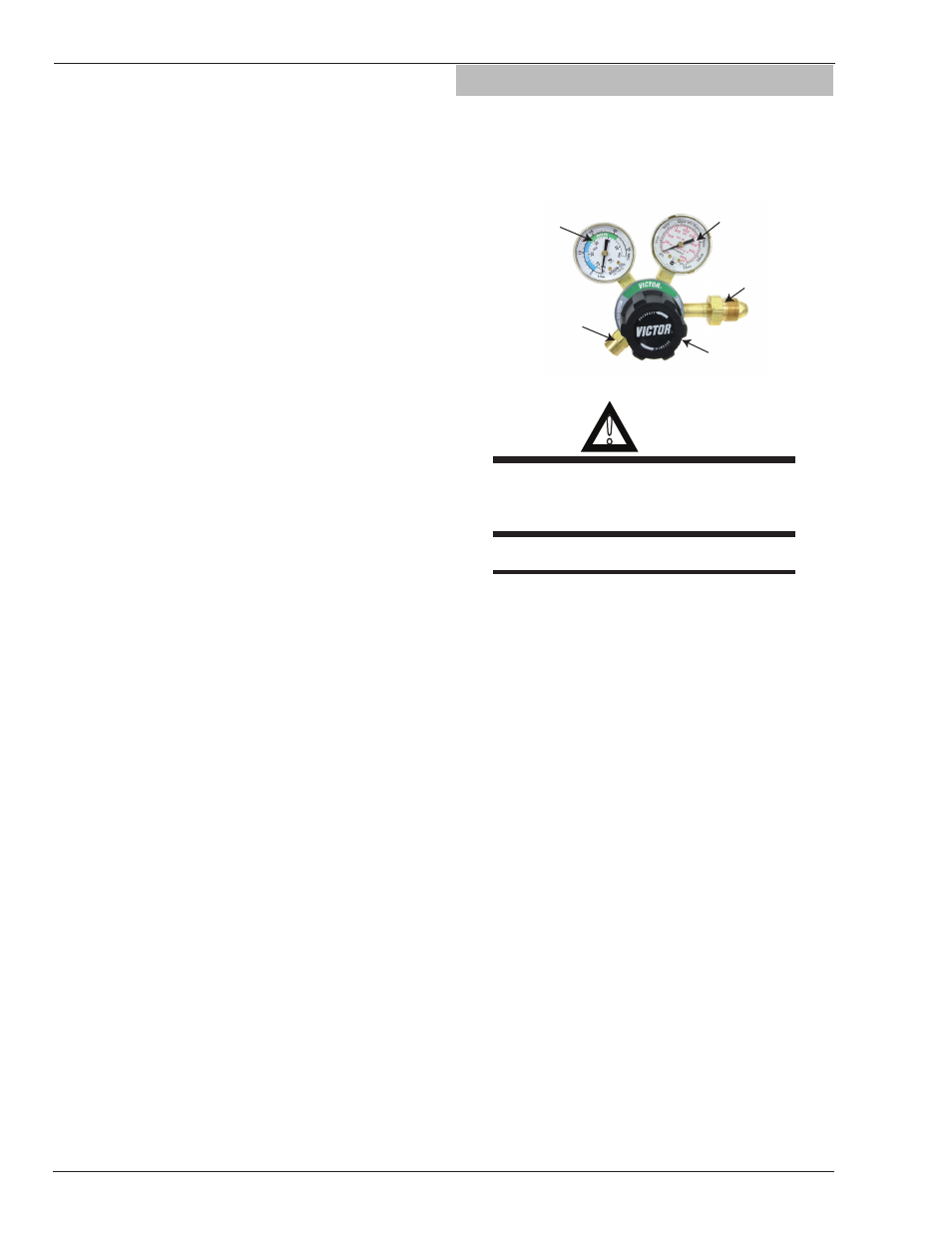

3.09 Victor Regulator

Pressure regulator (Figure 3-5) attached to the cylinder

valve reduce high cylinder pressures to suitable low

working pressures for welding, cutting, and other

applications.

FLOW GAUGE

HIGH PRESSURE

GAUGE (SUPPLY)

INLET

CONNECTION

OUTLET

CONNECTION

PRESSURE

ADJUSTING

SCREW

A-09414_AB

Figure 3-5: Victor CS Regulator

!

WARNING

Use the regulator for the gas and pressure for

which it is designed. NEVER alter a regulator

for use with any other gas.

NOTE

Regulators purchased with open 1/8”, 1/4”,

3/8”, or 1/2” NPT ports must be assembled

to their intended system.

1. Note the maximum inlet pressure stamped on the

regulator. DO NOT attach the regulator to a system

that has a higher pressure than the maximum rated

pressure stamped on the regulator.

2. The regulator body will be stamped “IN” or “HP” at the

inlet port. Attach the inlet port to the system supply

pressure connection.

3. Wrap pipe threads with Teflon tape 1 1/2 to 2 turns to

effect a seal. If other sealants are used, they must be

compatible with the gas that will be used in the system.

4. If gauges are to be attached to the regulator and the

regu lator is stamped and listed by a third party (i.e.

“UL” or “ETL”). The following requirements must be

met:

a) Inlet gauges over 1000 PSIG (6.87 mPa) shall

conform with the requirements of UL 404,

“Indicating Pressure Gauges for Compressed Gas

Service.”

b) Place the 8 pin plug into the 8 pin socket. To

make connections, align keyway, insert plug,

and rotate threaded collar fully clockwise.

c) Place the TIG torch gas hose to the gas outlet

and tighten with a wrench. Caution: DO NOT

over tighten.

4. Using a secured Argon cylinder, slowly crack open

then close the cylinder valve while standing off to

the side of the valve. This will remove any debris

that may be around the valve & regulator seat area.

5. Install the regulator (for details of VICTOR regulator,

please refer to 3.09 ) and tighten with a wrench.

6. Connect one end of the supplied gas hose to the

outlet of the Argon regulator and tighten with a

wrench. Caution: DO NOT over tighten.

7. Connect the other end of the supplied gas hose to

the gas inlet fitting on the rear panel of the welder

and tighten with a wrench. Caution: DO NOT over

tighten.

8. Open the Argon Cylinder Valve to the fully open

position.

9. Connect the ground (work) clamp to your work

piece.

10. Set the DOWN SLOPE control knob to the desire weld

current ramp down time. Refer to Section 4.01.

11. Set the weld current control knob to the desired

amperage.

12. The tungsten must be ground to a blunt point

in order to achieve optimum welding results. It

is critical to grind the tungsten electrode in the

direction the grinding wheel is turning.

13. Install the tungsten with approximately 1/8” to ¼”

sticking out from the gas cup, ensuring you have

correct sized collet.

14. Tighten the back cap then open the valve on the

torch.

15. Plug the power cable into the appropriate outlet,

and turn the switch to the “ON” position. The power

L.E.D. light should illuminate. Set the “Process

Selection Switch” to HF TIG

16. You are now ready to begin HF TIG Welding.