Cutmaster 102 – Tweco 102 Cutmaster User Manual

Page 64

CUTMASTER 102

SERVICE

Manual 0-4997

5T-2

5T.02 Inspection and Replacement of

Consumable Torch Parts

WARNING

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the AC

indicator light of the Power Supply is ON.

Remove the consumable torch parts as follows:

NOTE

The shield cup holds the tip and starter cartridge

in place. Position the torch with the shield cup

facing upward to prevent these parts from falling

out when the cup is removed.

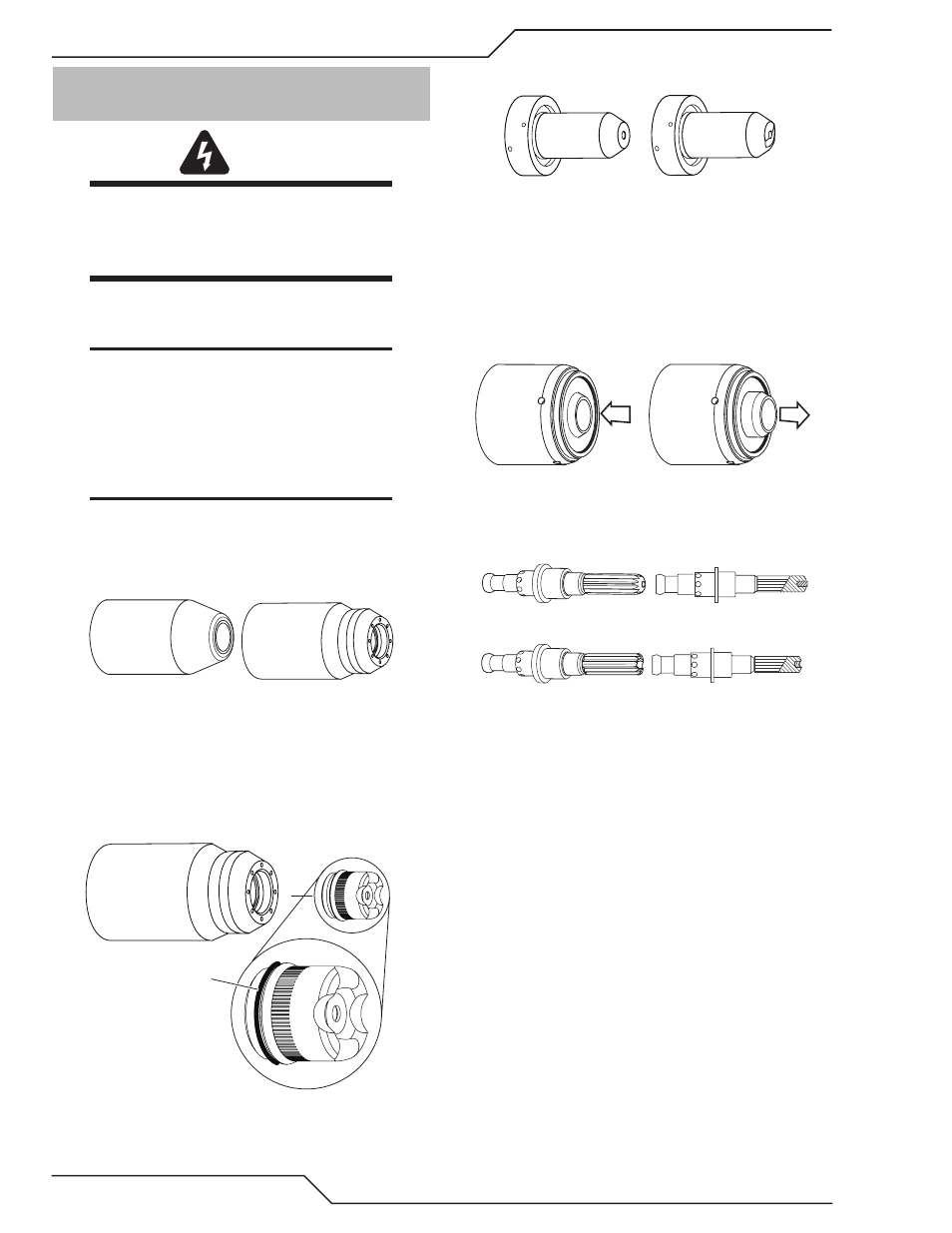

1. Unscrew and remove the shield cup from the torch.

NOTE

Slag built up on the shield cup that cannot be re-

moved may effect the performance of the system.

2. Inspect the cup for damage. Wipe it clean or replace

if damaged.

Art # A-08067

Shield Cups

3. On torches with a shield cup body and a shield

cap or deflector, ensure that the cap or deflector

is threaded snugly against the shield cup body. In

shielded drag cutting operations (only), there may

be an O-ring between the shield cup body and drag

shield cap. Do not lubricate the O-ring.

Drag Shield Cap

Shield

Cup Body

O-Ring No. 8-3488

Art # A-03878

4. Remove the tip. Check for excessive wear (indicated

by an elongated or oversized orifice). Clean or

replace the tip if necessary.

Good Tip

Worn Tip

A-03406

Example of Tip Wear

5. Remove the starter cartridge. Check for excessive

wear, plugged gas holes, or discoloration. Check the

lower end fitting for free motion. Replace if neces-

sary.

Art # A-08064_AC

Spring-Loaded

Lower End Fitting

Full Compression

Spring-Loaded

Lower End Fitting at Reset /

Full Extension

6. Pull the Electrode straight out of the Torch Head.

Check the face of the electrode for excessive wear.

Refer to the following figure.

Worn Electrode

New Electrode

Art # A-03284

Electrode Wear

7

. Reinstall the Electrode by pushing it straight into the

torch head until it clicks.

8

. Reinstall the desired starter cartridge and tip into the

torch head.

9. Hand tighten the shield cup until it is seated on the

torch head. If resistance is felt when installing the

cup, check the threads before proceeding.

This completes the parts replacement procedures.