Ultra-cut 400, 07 power supply status codes – Tweco 400 Ultra-Cut User Manual

Page 86

OPERATION

4-12

Manual No. 0-5164

ULTRA-CUT 400

4.07 Power Supply Status Codes

On start-up and during operation, the power supply control circuitry performs various tests. If the circuitry detects

a condition requiring operator attention, the status indicator on the control panel flashes a 2-part code to indicate

a code group and then a particular condition within the group. After 4 seconds, the sequence repeats.

Example: Indicator flashes 4 times; the condition is in group 4. After a 1.2 second delay, the indicator blinks 3

times; the condition code is 4-3, indicating that the coolant is overheating. After a 4-second delay, the indicator

repeats the sequence until the condition is corrected.

Some conditions can be active indefinitely, while others are momentary. The power supply latches momentary

conditions; some momentary conditions can shut down the system. The indicator may show multiple conditions

in sequence; it is important to recognize all possible conditions that may be displayed.

NOTE

These codes are for systems with Firmware versions 2.4 or later. If your system’s Firmware is a prior

version, contact your distributor for updates.

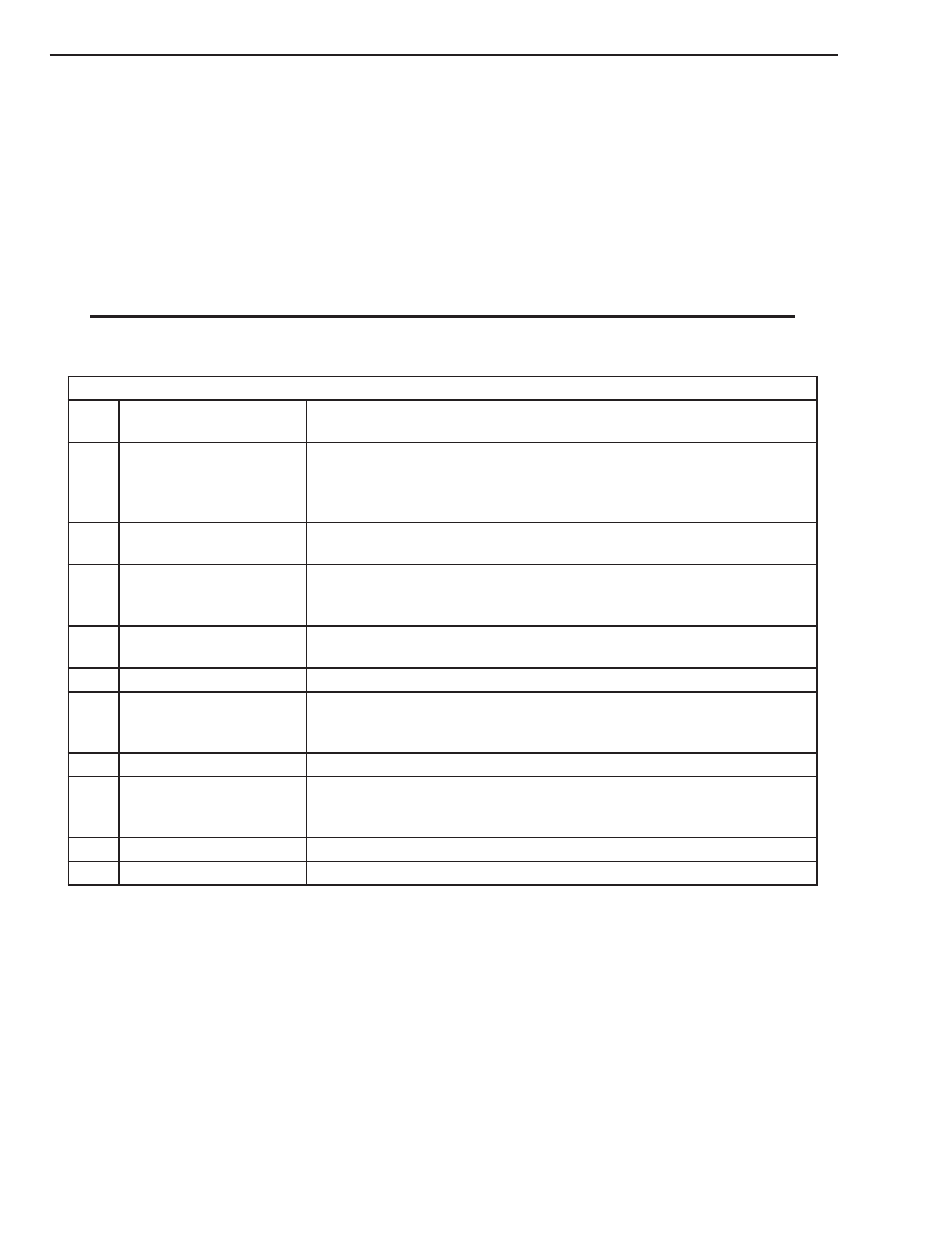

Fault Code Key

Error

Code

Error

Remedy / Comments

1-1

Plasma Disabled or Missing

AC Input Phase

Plasma Enable Off ; External E-Stop Activated or CCM TB1-1&2 jumper miss-

ing; Missing AC Phase; No power to GCM 2000 or 2010 Gas Control, check

GCM control cable connected, reset CP4 or CP5 circuit breaker in power supply,

blown fuse F19 in GCM.

1-2

Pilot Ignition Failure

Pilot did not start within 15 seconds. Preflow pressure too high; Defec-

tive Arc Starter

1-3

Lost Pilot

Pilot went out while CNC Start active Ensure process loaded agrees with torch

parts installed; If custom process cut current too low or preflow pressure too

high. Torch consumable parts worn

1-4

Transfer Lost

Arc was transferred to work for more than 50 ms and then went out while CNC

Start still active. Standoff too high; Current set too low.

1-5

Off the Plate

Function not currently enabled

1-6

Pilot Timed out no Transfer

Must transfer from Pilot to Cutting Arc in 85 ms. (SW8-1 OFF) or 3 sec. (SW8-

1 ON). Standoff too high or void in work under torch; cut current too low for

consumables; Preflow pressure too low.

1-7

Reserved

No information available; Contact customer service

1-8

Possible Shorted Torch

Tip voltage too close to electrode voltage. Plasma supply pressure too low;

Leak in Plasma hose to torch; plasma pressure / flow may be too low or cut cur-

rent too high. Torch consumable parts worn; Shorted torch body

1-9

Reserved

No information available; Contact customer service

1-10 Reserved

No information available; Contact customer service