Appendix 2: grounding a cutting machine, Sc-3000 – Tweco SC-3000 User Manual

Page 72

SC-3000

APPENDIX

A-2

Manual 0-5100

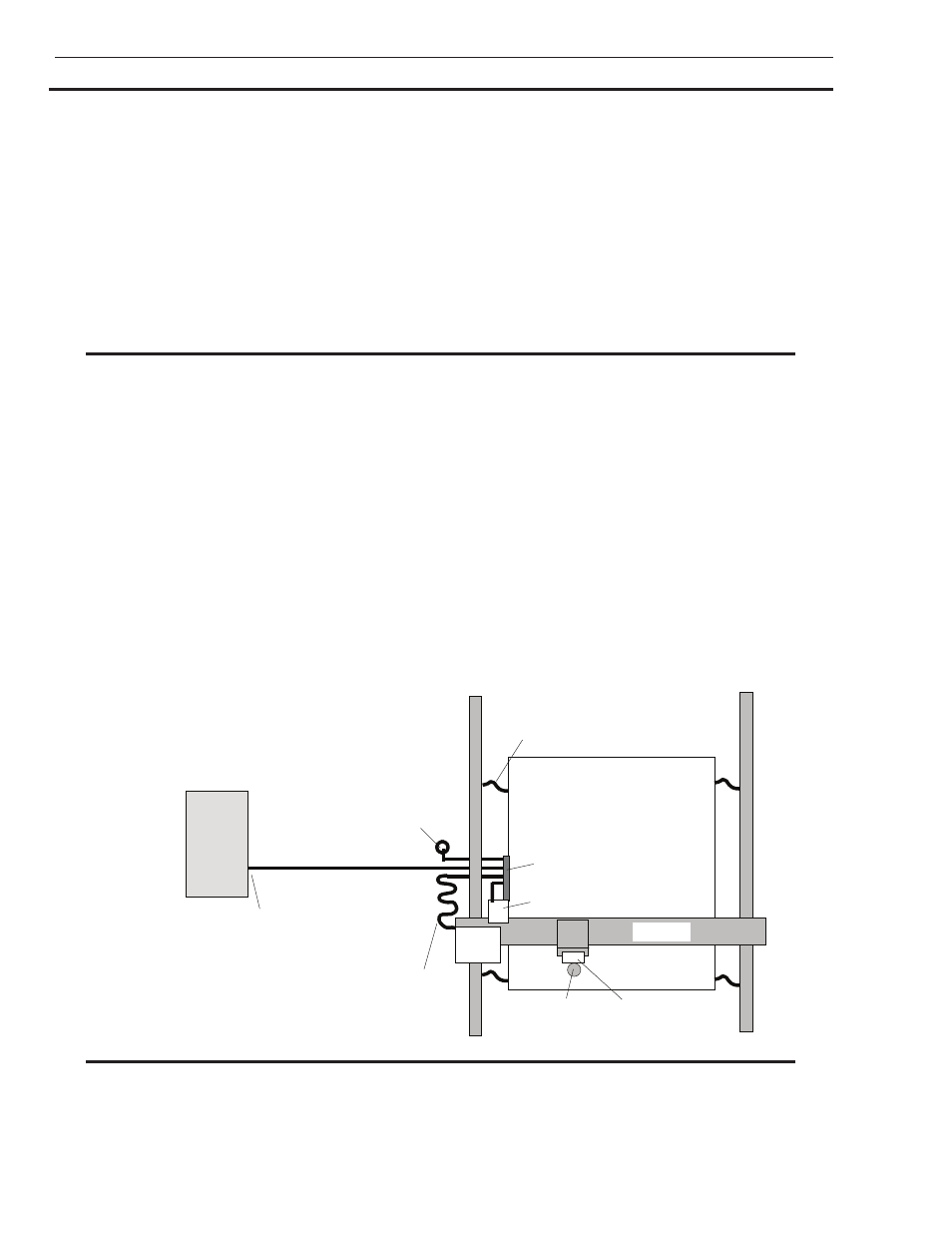

APPENDIX 2: GROUNDING A CUTTING MACHINE

This information and recommendations which are described here should help to understand the importance of

correct machine grounding

Furthermore, all manufacturer installation instructions for cutting machines and plasma sources must be complied

with.

The accurate grounding of plasma cutting machines is one of the most important parts to ensure proper function-

ing. This prevents electromagnetic interference (EMI) problems which can disturb electrical devices and causes a

malfunction.

The aim is to achieve low electrical impedance from machine ground to earth ground.

This is described below.

NOTE

It implicates an improper use if no sufficient grounding is provided !

All components of the machine which need grounding must be connected to a single star point. Preferably this star

point is affixed at the cutting table and is connected to a ground rod by a suitable cable.

The distance to the star point should be less than 10' (3 meters). The resistance to ground should be less than 1

Ohms.

All metallic parts of the machine (servos, control console and height control components) must be connected to the

star point.

The four corners of the cutting table must be connected to the rail.

Example of a Cutting machine with a cutting current up to 150 A. The same cables used for welding can be used

as grounding cables.

Figure1: View from above (top view)

Star Point

Rail

Gantry

Torch

Lifter

Plasma source

Positive Plasma Voltage Output

(Work Lead)

width of cable 1/0 AWG equivalent 50 qmm

Torch

width of cable 2/0 AWG

equivalent 70 qmm

on all 4 corners

Cutting Table

stranded wire 2/0 AWG

equivalent 70 qmm

Chassis of Machine Control

Ground Rod

width of cable 2/0 AWG

equivalen t 70 qmm

Rail

Art # A-08942_AB

NOTE

For a higher cutting current (more than 150 A) the width of cables should be increased to 4/0 AWG, equivalent

95 qmm.