Appendix 7: pak master 75xl plus system data – Tweco PCM - 102 Machine Torch User Manual

Page 68

APPENDIX

A-12

Manual 0-2818

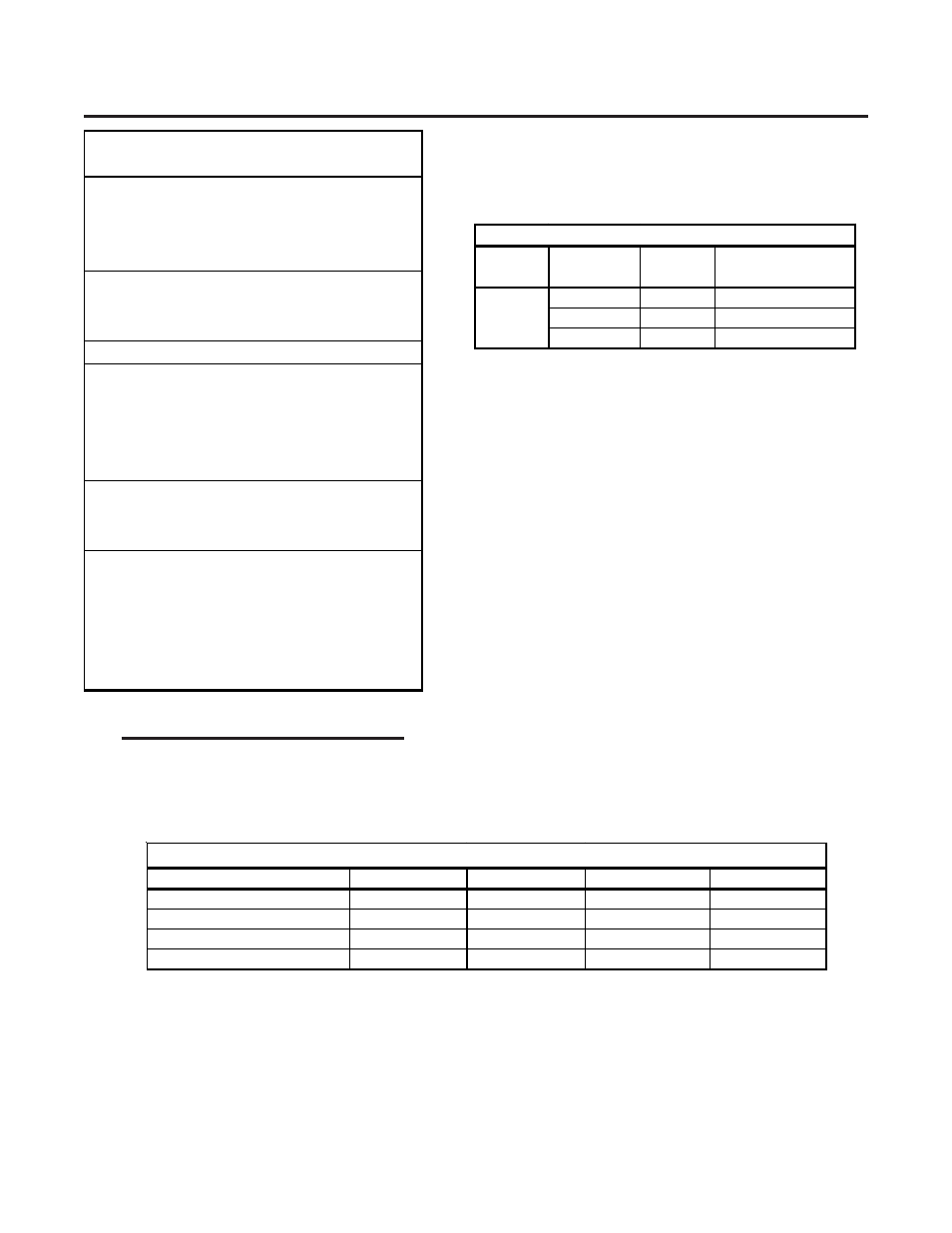

Application

Electrode

Gas Distributor

Tip

Shield Cup

Drag Cutting

9-8407

8-7501

8-7503

8-7500

Cutting (without Standoff Cup)

9-8407

8-7501

9-7726

8-7500

Cutting (with Standoff Cup)

9-8407

8-7501

9-7726

8-7507

Gouging

9-8407

8-7508

8-7506

8-7500

Consumable Matrix For Pak Master 75XL Plus

APPENDIX 7: PAK MASTER 75XL PLUS SYSTEM DATA

NOTE

For CE Applications refer to Appendix 9.

Cut Quality on Various Materials and Thicknesses

The following table defines the cut quality on various

materials and thicknesses:

Cut Quality on Various Materials

Material

Type of

Type of

Cut

Thickness

Material

Gas

Characteristics

Carbon Steel

Air

Good - Excellent

Stainless

Air

Good - Excellent

Aluminum

Air

Good - Excellent

Gage

to

3/4 inch

Description of Cut Characteristics:

Excellent -

Minimum bevel (0 - 4°), minimum kerf (2 x tip

orifice diameter), little or no dross, smooth cut

surface.

Good -

Slight bevel (0 - 10°), slightly wider kerf (2-1/2 x tip

orifice diameter), some dross (easily removed), me-

dium-smooth cut surface, slight top edge rounding.

Cutting Range

Material

Most Metals

Up to

3/4 inch (19 mm)

Speed

10 ipm (0.25 mpm)

Pierce Rating

Material

Carbon Steel

Thickness

3/8 inch (9.5 mm)

Transfer Distance

3/8 inch (9.5 mm)

Gouging

Width

1/8 inch (3.2 mm)

Depth

1/8 inch (3.2 mm)

Number Passes

Single

Speed

20 ipm (0.5 mpm)

Bevel Cut Capability

Degrees

0° to 45°

Material Thickness

1/4 inch (6.3 mm)

Gas Requirement

Type Gas

Air

Operating Pressure

60 psi (4.1 bar)

Max Input Pressure

125 psi (8.6 bar)

Cutting & Gouging

Total Flow

300 scfh (142 lpm)

Torch Specifications For

Pak Master 75XL Plus Power Supply