Workpiece power supply + _ c b a – Tweco PCM - 102 Machine Torch User Manual

Page 17

Manual 0-2818

2-3

INTRODUCTION

;;

;;

;;

;

;

;

;

;

;;

;;

A-00002

Workpiece

Power

Supply

+

_

C

B

A

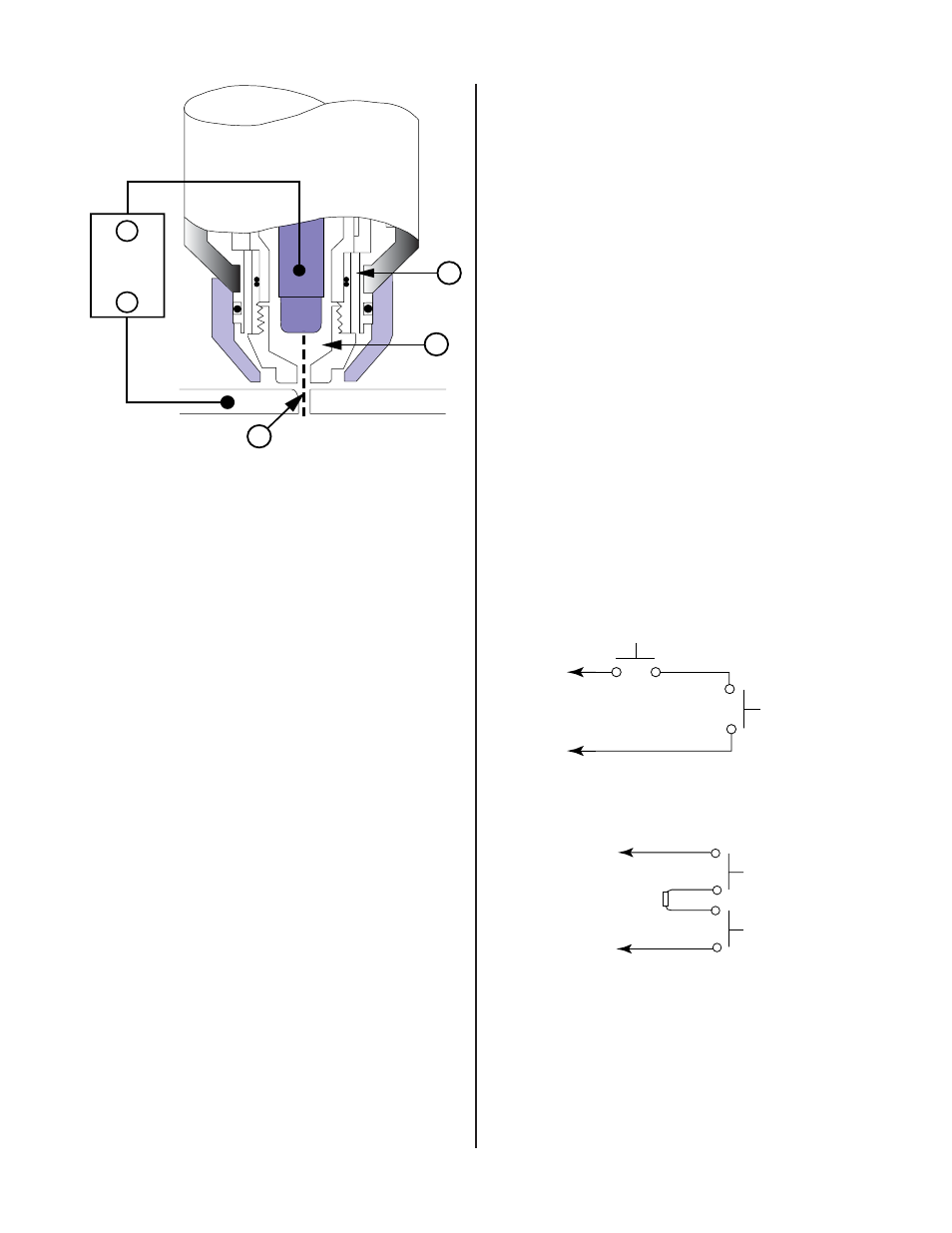

Figure 2-2 Typical Torch Head Detail

By forcing the plasma gas and electric arc through a small

orifice, the torch delivers a high concentration of heat to a

small area. The stiff, constricted plasma arc is shown in

Zone C (Figure 2-2). Direct current (DC) straight polarity is

used for plasma cutting, as shown in the illustration.

Zone A (Figure 2-2) is used as a secondary gas that cools

the torch. This gas assists the high velocity plasma gas in

blowing the molten metal out of the cut allowing for a fast,

slag-free cut.

B. Gas Distribution

The single gas used is internally split into plasma and sec-

ondary gases.

The plasma gas flows into the torch through the negative

lead, through the gas distributor, around the electrode,

and out through the tip orifice.

The secondary gas flows down around the outside of the

torch gas distributor, and out between the tip and shield

cup around the plasma arc.

C. Pilot Arc

When the torch is started a pilot arc is established be-

tween the electrode and cutting tip. This pilot arc creates

a path for the main arc to transfer to the work.

D. Capacitive Discharge

Because direct current (DC) alone is not sufficient to strike

and maintain the pilot arc, capacitive discharge is also used.

The high voltage jumps between the tip and electrode with

the DC following.

E. Main Cutting Arc

DC power is also used for the main cutting arc. The nega-

tive output is connected to the torch electrode through the

torch lead. The positive output is connected to the work-

piece via the work cable and to the torch through a pilot

wire.

F. Interlocks

One pressure switch acts as an interlock for the gas sup-

ply. If supply pressure falls below minimum requirements

the pressure switch will open, shutting off the DC power,

and the GAS indicator will go off. When adequate gas

supply pressure is available the pressure switch will close,

allowing power to be resumed for cutting.

G. Parts-In-Place (PIP)

The torch head has built-in contacts called Parts-In-Place

(PIP). These two contacts are made through the canted

coiled spring inside the shield cup when it is installed. The

torch will fail to operate if these contacts are not made.

A-00458

Torch Switch

PIP Pin

PIP Pin

Shield Cup

To Control

Cable Wiring

Figure 2-3A Parts-In-Place (PIP) Diagram - Machine

Torch

A-03761

Torch Trigger

PIP Switch

Shield Cup

To Control

Cable Wiring

Torch Switch

Figure 2-3B Parts-In-Place (PIP) Diagram - Hand

Torch