Tweco PCM - 102 Machine Torch User Manual

Page 61

Manual 0-2818

A-5

APPENDIX

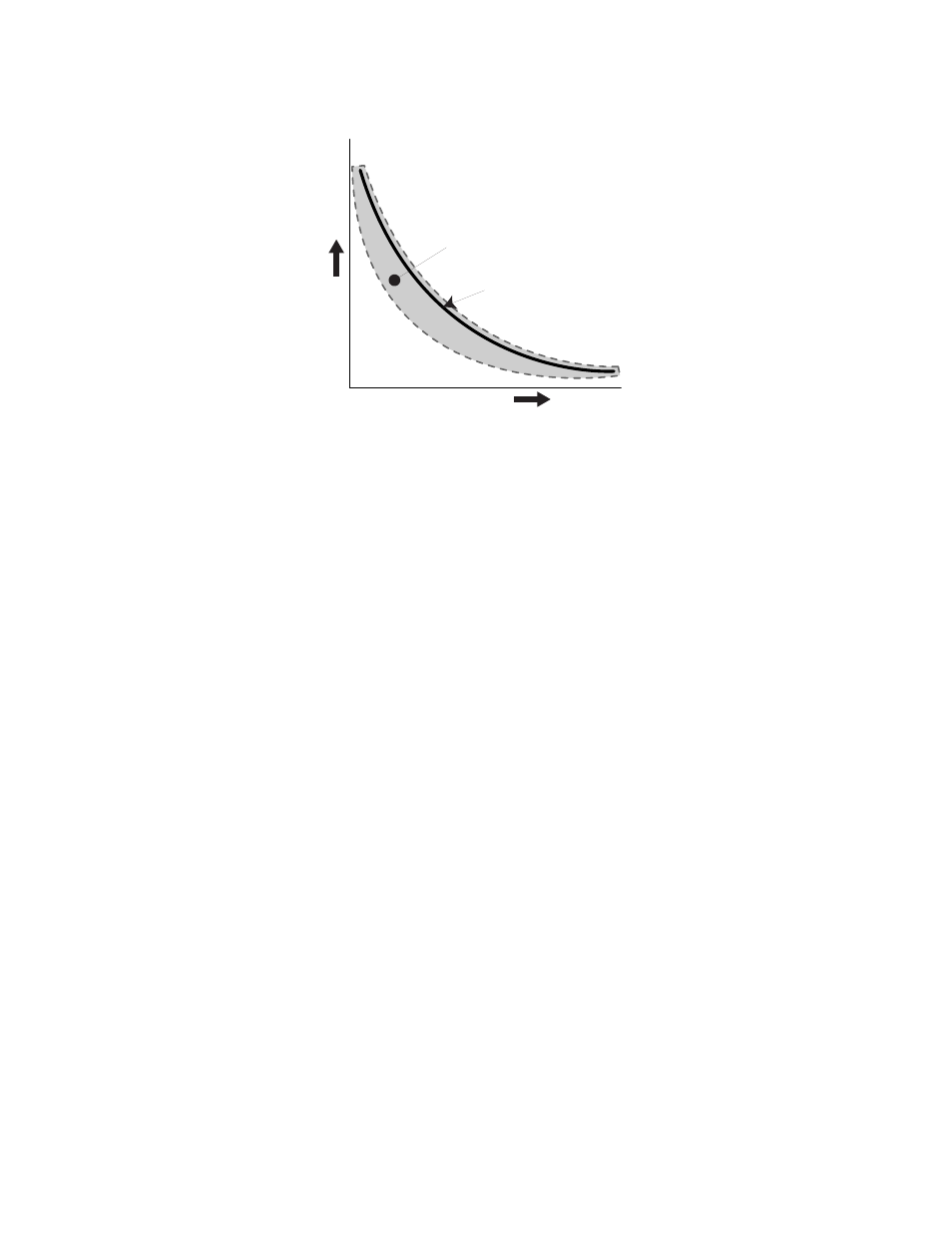

B. Hand Cutting Versus Machine (Mechanized) Cutting Speeds

Material Thickness

Speed

Machine Cutting

Speeds

Hand Cutting Speeds

(Shaded Area)

A-02947

Hand cutting speeds can be much less than those obtained from Machine (Mechanized) Type applications. Hand

cutting application speeds mostly depend on operator experience. The cut quality obtained at slower speeds for a

Hand application is just as good as those obtained from a Machine application. As the cut speeds increase or de-

crease from the Machine applications the following may occur:

• If cut speed is too fast the cut may exhibit one or more of the following: Insufficient Penetration, High Speed

Dross, Poor Consumable Life, Excessive Bevel Angle.

• If cut speed is too slow the cut may exhibit one or more of the following: Main Arc Extinguishes, Slow Speed

Dross, Wandering (Unstable) Arc, Poor Consumable Life.

C. Frequently Asked Questions

Q. What Electrode can be used?

A. Only SureLok Electrodes, 9-8402 and 9-8407 may be used. Depending on the application and power supply

the General Purpose Electrode (9-8402) provides good all around characteristics and performance. The

MaximumLife Electrode (9-8407) design offers improved electrode cooling resulting in a significant improve-

ment in parts life.

Q. Which Tip can be used?

A. All the Tips listed on the Appendix Page for the selected Power Supply application can be used. Select the

proper Tip for the desired application. It is recommended to use the Cutting / Drag Tip for general purpose

drag and light cutting applications. The Gouging Tip is recommended for gouging applications only. The

Standoff Tip can be used for standoff cutting applications for improved cut quality and speed.

Q. What if Electrode parts life is low?

A. Try using the MaximumLife Electrode.