05 troubleshooting guide, 05 troubleshooting guide -3 – Tweco PCM - 102 Machine Torch User Manual

Page 35

Manual 0-2818

5-3

SERVICE

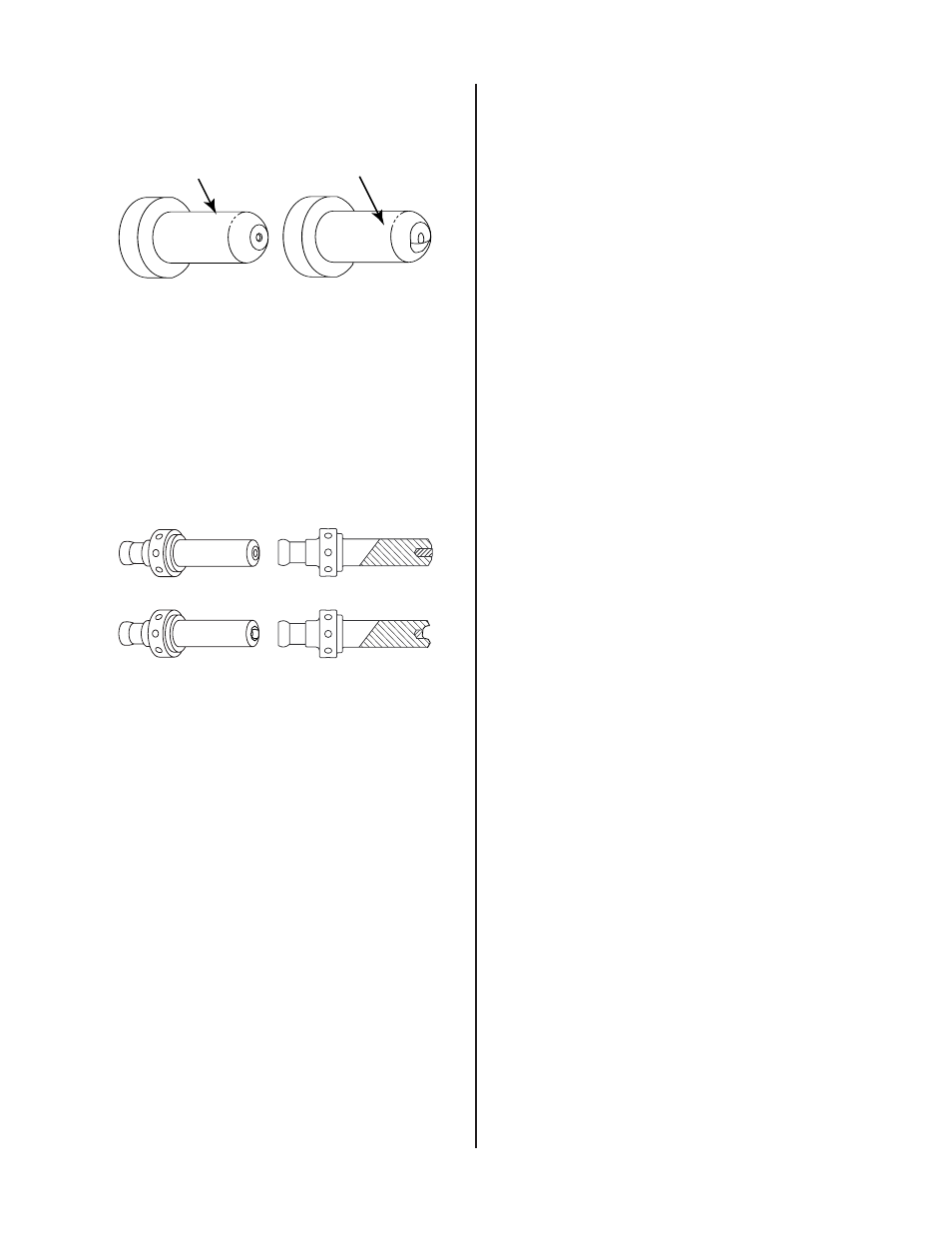

3. Remove the tip. Check for excessive wear (indicated

by an elongated or oversized orifice). Clean or re-

place the tip if necessary.

Good Tip

Worn Tip

A-00942

Figure 5-2 Tip Wear

4. Remove the gas distributor and check for excessive

wear, plugged gas holes, or discoloration. Replace if

necessary.

5. Remove the SureLok Electrode by pulling it straight

out of the Torch Head. Refer to the following figure

and check the face of the electrode for excessive wear.

Worn Electrode

New Electrode

A-02794

Figure 5-3 Electrode Wear

6

. Reinstall the SureLok Electrode by pushing it straight

into the torch head until it clicks.

7

. Reinstall the desired gas distributor and tip into the

torch head.

8. Hand tighten the shield cup until it is seated on the

torch head. If resistance is felt when installing the

cup, check the threads before proceeding.

5.05 Troubleshooting Guide

This subsection covers troubleshooting that requires dis-

assembly and electronic measurements. It is helpful for

solving many of the common problems that can arise with

this torch assembly.

How to Use This Guide

The following information is a guide to help the Customer

/ Operator determine the most likely causes for various

symptoms.

This guide is set up as follows:

X. Symptom (Bold Type)

Any Special Instructions (Text Type)

1. Cause (Italic Type)

a. Check / Remedy (Text Type)

Locate your symptom, check the causes (easiest listed first)

then remedies. Repair as needed being sure to verify that

unit is fully operational after any repairs.

Troubleshooting

A. Torch will not pilot when torch switch is activated

1. Power Supply RUN / SET / LATCH switch in SET

position

a. Place RUN / SET / LATCH switch to RUN po-

sition.

2. Parts - In - Place (PIP) not satisfied.

a. Check canted coiled spring inside shield cup

3. Faulty Torch Switch

a. Check for continuity

4. Faulty torch parts

a. Inspect torch parts and replace if necessary. Re-

fer to Section 5.04, Inspection and Replacement

Consumable Torch Parts

5. Gas pressure too high

a. Set proper operating gas pressure.

6. Faulty components in torch and leads assembly

a. Inspect torch assemblies and replace if neces-

sary. Refer to Section 5.06, Torch & Leads

Troubleshooting.

7. Faulty components in power supply system components

a. Return for repair or have qualified technician

repair per Service Manual.