Section 5: customer/operator service, 01 introduction, 02 general maintenance – Tweco 150XL CE PAK Master Without Latch Circuit User Manual

Page 35: Section 5, Customer/operator service -1, 01 introduction -1 5.02 general maintenance -1

Manual 0-2727

5-1

CUSTOMER/OPERATOR SERVICE

SECTION 5:

CUSTOMER/OPERATOR

SERVICE

5.01 Introduction

This section describes maintenance procedures, basic

troubleshooting and service performable by operating

personnel. No other adjustments or repairs are to be at-

tempted by other than properly trained personnel.

5.02 General Maintenance

A. Routine Maintenance

NOTE

Refer to Appendix 4 for a recommended mainte-

nance schedule for water cooled plasma cutting

systems.

Routine maintenance for the Power Supply should in-

clude an occasional thorough cleaning and inspection. The

frequency depends on the usage and the operating envi-

ronment.

WARNING

Disconnect primary power at the source before as-

sembling or disassembling power supply, torch

parts, or torch and leads assemblies.

B. Power Supply Cleaning

To clean the unit, open the enclosure and use a vacuum

cleaner to remove any accumulated dirt and dust. The

unit should also be wiped clean. If necessary, solvents

that are recommended for cleaning electrical apparatus

may be used.

WARNING

Do NOT blow air into the power supply during

cleaning; make sure to always blow air out of the

unit. Blowing air into the unit can cause metal

particles to interfere with sensitive electrical com-

ponents and cause damge to the unit.

While the unit is open, inspect the wiring in the unit. Look

for any frayed wires or loose connections that should be

corrected.

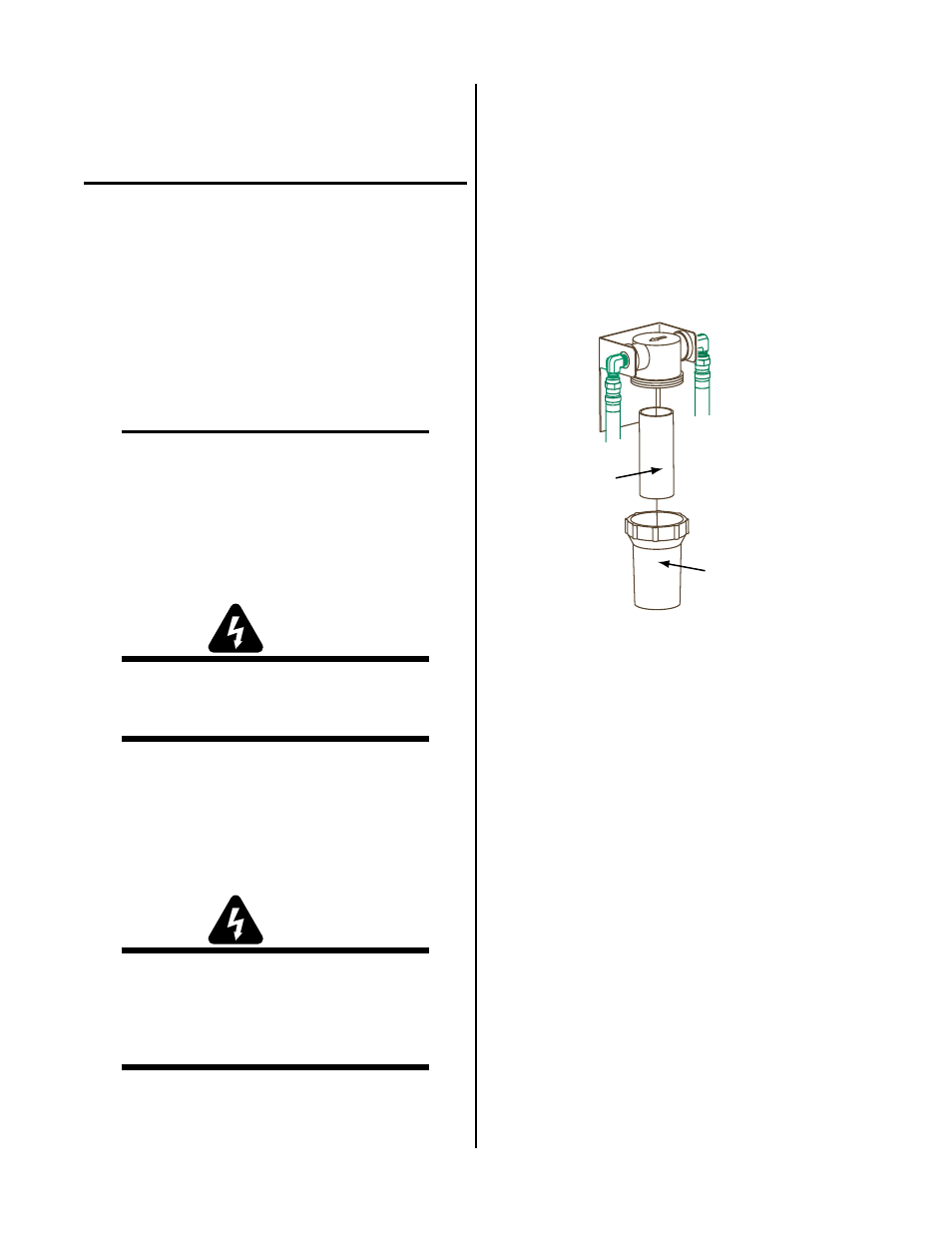

C. Coolant Filter Assembly Cleaning

The Coolant Filter Screen should be cleaned periodically.

To gain access to the Coolant Filter Assembly, remove the

right side panel when viewed from front of unit. Remove

the Filter Screen by unscrewing the filter holder from the

Coolant Filter Assembly. Clean the filter screen by rins-

ing with hot soapy water. Remove soap residue by rins-

ing with clean hot water. Be sure that all the soap has

been removed and the screen is dry of water before re-

installing in the Coolant Filter Assembly.

A-02152

Filter Holder

Filter

Figure 5-1 Coolant Filter Assembly

D. In-Line Coolant Filter Assembly Cleaning

The In-line Coolant Filter Screen should be cleaned peri-

odically. To gain access to the In-Line Coolant Filter As-

sembly remove the right side panel (when viewed from

the front of unit). Remove the Filter Screen by unscrew-

ing the Filter Holder from the In-Line Coolant Filter As-

sembly. Clean the Filter Screen by rinsing with hot soapy

water. Remove soap residue by rinsing with clean hot

water. Be sure that all the soap has been removed and

the screen is dry of water before re-installing in the In-

Line Coolant Filter Assembly.