06 system operation, 06 system operation -6 – Tweco 150XL CE PAK Master Without Latch Circuit User Manual

Page 32

OPERATION

4-6

Manual 0-2727

Description of Cut Characteristics

Excellent

- Minimum bevel (0 - 4°), minimum kerf (2 x

tip orifice diameter), little or no dross, smooth

cut surface.

Good

- Slight bevel (0 - 10°), slightly wider kerf (2-1/2 x

tip orifice diameter), some dross (easily re-

moved), medium-smooth cut surface, slight top

edge rounding.

Fair

- Excessive bevel (over 10°), wide kerf (over 2-1/2 x

tip orifice diameter), medium to heavy dross,

rough cut surface, top edge rounding.

NOTES

Cut quality depends heavily on set-up and param-

eters such as torch standoff, alignment with the

workpiece, cutting speed, gas pressures, and op-

erator ability.

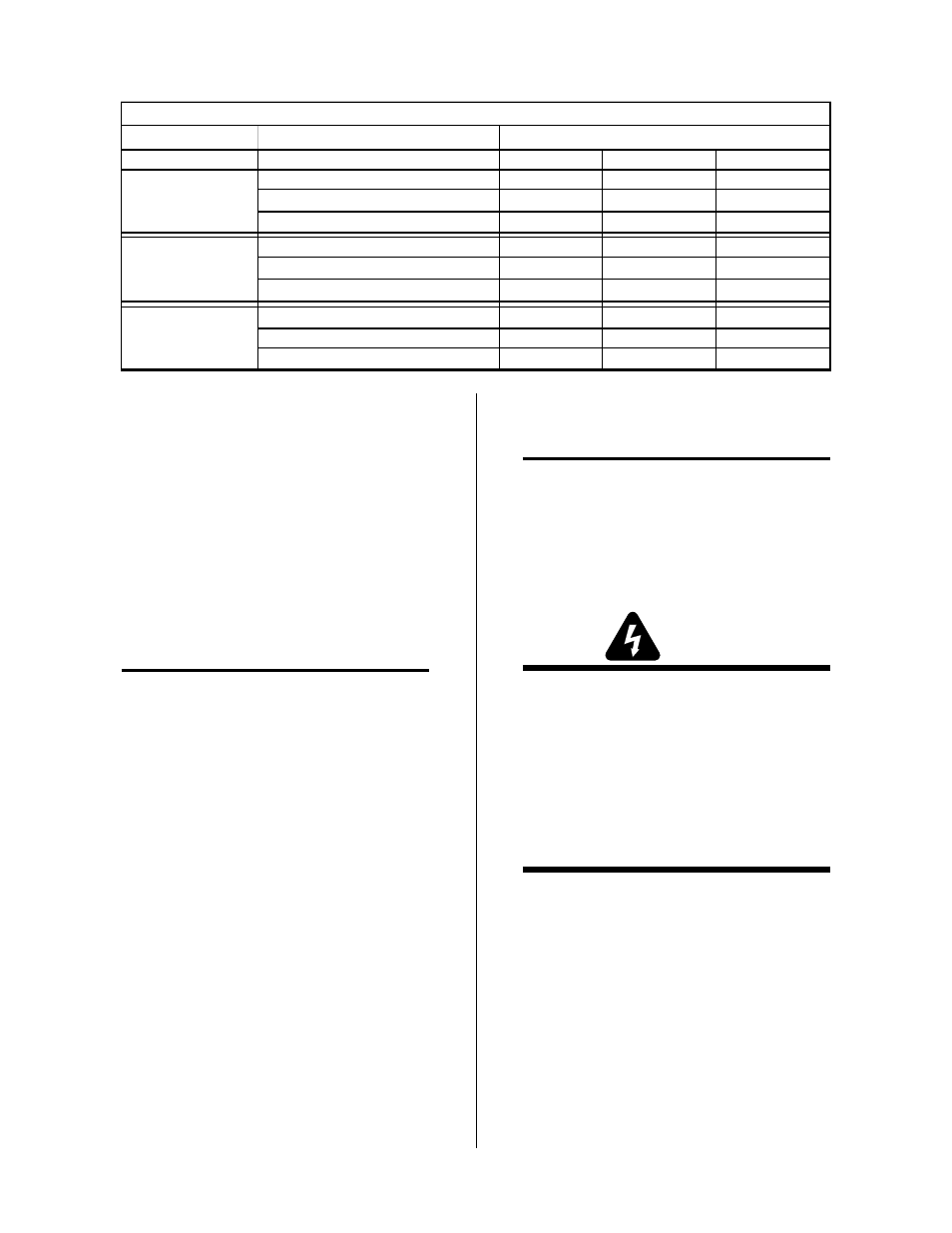

Cut Quality on Various Materials

Types of Material

Type of Gases

Material Thickness

Carbon Steel

Stainless

Aluminum

Air Plasma and

Gage (0.5 mm)

Excellent

Good-Excellent Good-Excellent

Air Secondary

Gage to 1 inch (0.5 mm - 25.4 mm)

Excellent

Good

Good

1 to 1-1/2 inch (25.4 mm - 38.1 mm)

Excellent

Good

Good

Nitrogen Plasma

Gage (0.5 mm)

NR

Good-Excellent Good-Excellent

and Air or CO2

Gage to 1/2 inch (0.5 mm - 12.7 mm)

NR

Good-Excellent Good-Excellent

Secondary

1/2 to 1-1/2 inch (12.7 mm - 38.1

)

NR

Good-Excellent Good-Excellent

Ar/H2 Plasma and

Gage to 1/4 inch (0.5 mm - 6.4 mm)

NR

NR

NR

N2 or CO2

1/4 to 1-1/4 inch (6.4 mm - 31.8 mm)

NR

Good

Excellent

Secondary

1/2 to 1-1/2 inch (12.7 mm - 38.1

)

NR

Good

Excellent

4.06 System Operation

NOTE

Frequently review the safety precautions at the front

of this manual.

This section contains operating information which is spe-

cific to the power supply. Detailed operating informa-

tion for torches can be found in the appropriate Torch

Instruction Manual.

WARNINGS

Disconnect primary power at the source before as-

sembling or disassembling power supply, torch

parts, or torch and leads assemblies, or adding cool-

ant.

It is not enough to simply move the ON/OFF

switch on the unit to OFF position when cutting

operations have been completed. Always open the

power supply disconnect switch five minutes after

the last cut is made.

A. Operational Suggestions

The suggestions below should be followed in all cutting

and gouging operations:

1. Wait five minutes before setting the ON/OFF switch

to OFF after operation. This allows the cooling fan to

run to dissipate operating heat from the power sup-

ply.

2. For maximum parts life, do not operate the pilot arc

any longer than necessary.

3. Use care in handling torch leads and protect them from

damage.