08 ground connections for mechanized applications – Tweco 150XL CE PAK Master Without Latch Circuit User Manual

Page 23

Manual 0-2727

3-7

INSTALLATION PROCEDURES

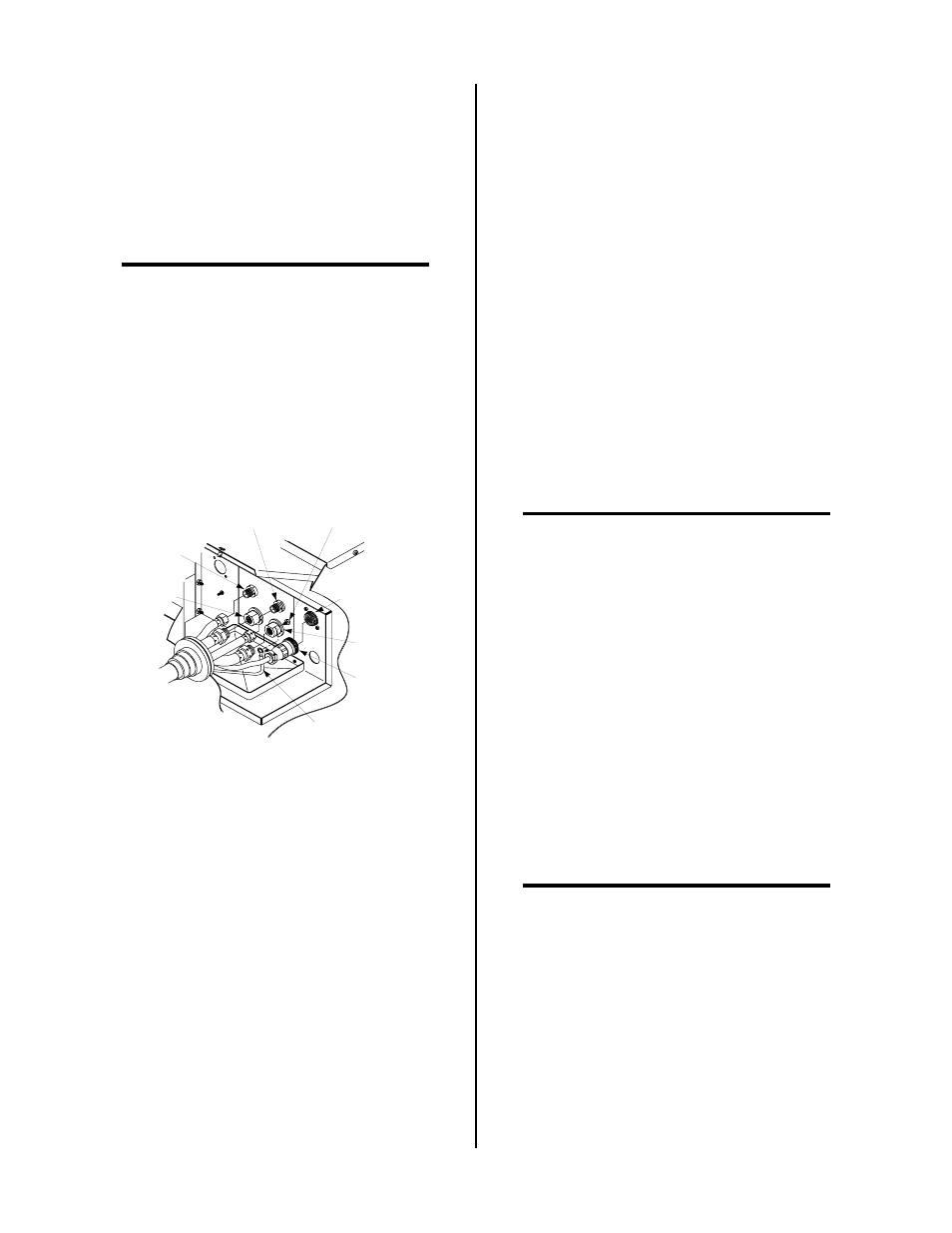

Connect the CNC Control Cable and Torch Leads to the

Power Supply using the following procedure:

1.

Open the Access Panel to gain access to the Torch

Bulkhead Panel.

2.

Feed the connector on the end of the CNC Control

Cable through the rubber boot on the front panel

of the Power Supply (see NOTE).

NOTE

Feed the Control Cable through the rubber boot first

as there will not be enough space inside the rubber

boot for the connector if the Coolant and Gas Leads

have been fed through the rubber boot first.

3.

Connect the CNC Control Cable connector to the

Control Cable connector on the Torch Bulkhead

Panel.

4.

Feed the end of the Torch Leads through the rub-

ber boot.

A-02113

Secondary

Gas

Plasma (+)

Gas

Control Cable

Connector

Coolant

Return

Coolant

Supply (-)

CNC Control

Cable

Torch Leads

Shield Stud

Shield Wire

With Ring Lug

Figure 3-9 Shielded Machine Torch Connections

5.

Connect the Torch Leads Shield Wire per the fol-

lowing procedure:

a. Remove one nut and star washer from the torch

leads shield stud on the Torch Bulkhead Panel.

b. Place the ring lug from the Torch Leads Shield

Wire over the shield stud.

c. Secure the wire with the nut and star washer.

6.

Connect torch coolant and gas leads to connectors

on the Torch Bulkhead Panel.

7.

Close the Access Panel and turn the two latching

screws.

8.

Check the torch for proper parts assembly.

9.

Connect the other end of the CNC Control Cable

to the desired equipment.

3.08 Ground Connections For

Mechanized Applications

A. Electromagnetic Interference (EMI)

Pilot arc initiation generates a certain amount of electro-

magnetic interference (EMI), commonly called RF noise.

This RF noise may interfere with other electronic equip-

ment such as CNC controllers, remote controls, height

controllers, etc. To minimize RF interference, follow these

grounding procedures when installing mechanized sys-

tems:

B. Grounding

1. The preferred grounding arrangement is a single point

or “Star” ground. The single point, usually on the cut-

ting table, is connected with 1/0 (42 mm

2

) or larger

wire to a good earth ground (refer to paragraph ‘C’,

Creating An Earth Ground). The ground rod must be

placed as close as possible to the cutting table. Ideally

less than 10 ft (3.0 m), but no more than 20 ft (6.1 m).

NOTE

All ground wires should be as short as possible.

Wires of long length will have increased resistance

to RF frequencies. Smaller diameter wire has in-

creased resistance to RF frequencies, so using a

larger diameter wire is better.

2. Components that are mounted on the cutting machine;

CNC controller, plasma remote controls, height con-

trollers, remote arc starters, etc., should be grounded

to the cutting machine frame (chassis) with at least a

12 AWG (4 mm

2

) wire. Flat copper braid works even

better.

3. The cutting machine frame is then connected to the

“Star” point using AWG 6 (13.3 mm

2

) or larger wire.

4. The plasma power supply work cable (see NOTE) is

connected to the cutting table at the single point “Star”

ground.

NOTE

Do Not connect the work cable directly to the

ground rod.

5. Make sure work cable and ground cables are prop-

erly connected. The work cable must have a solid

connection to the cutting table. The work and ground

connections must be free from rust, dirt, grease, oil

and paint. If necessary grind or sand down to bare

metal. Use lock washers to keep the connections tight.

Using electrical joint compound to prevent corrosion

is also recommended.