Section 4: operation, 01 introduction, 02 operating controls – Tweco 150XL CE PAK Master Without Latch Circuit User Manual

Page 27: Section 4, Operation -1, 01 introduction -1 4.02 operating controls -1, A. front and access panel, B. control panel

Manual 0-2727

4-1

OPERATION

SECTION 4:

OPERATION

4.01 Introduction

This section provides a description of the CE Power Sup-

ply operating controls and procedures. Identification of

the Front and Rear Panel components is followed by op-

erating procedures.

4.02 Operating Controls

This subsection provides specific functional descriptions

of the Power Supply operating controls and indicators.

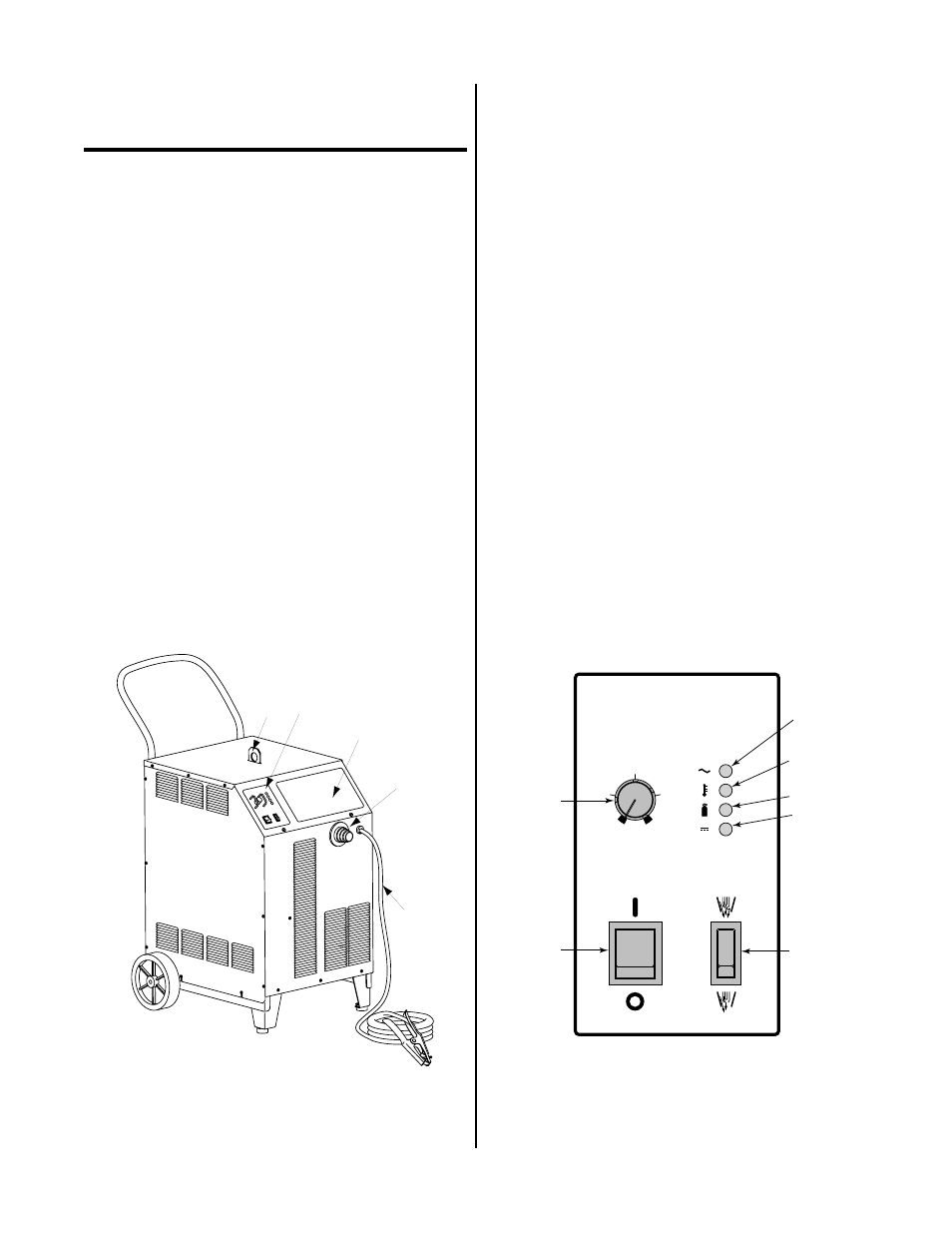

A. Front and Access Panel

1.

Control Panel

All operator controls, except gas pressure adjust-

ment, are located on this panel and include:

• Power ON/OFF and RUN/SET switches

• CURRENT control

• LED indicators for AC Power, TEMP, GAS/

Coolant, and DC.

A-02079

1

2

3

4

5

Figure 4-1 Front and Access Panels

2.

Access Panel

A panel to gain access to the bulkhead area con-

taining the torch connections.

3.

Torch Leads Input

Rubber Boot and hole in the front panel to feed

the torch leads through to the internal bulkhead

connections.

4.

Work Cable and Clamp

Work cable with clamp (factory installed).

5.

Lifting Eye

Used to lift the Power Supply with cable and hook.

B. Control Panel

1.

Current Control

Adjustment to set the desired output current be-

tween 30-120 amps. For drag cutting applications

set the control between 30 - 35 amps. The unit has

an automatic fold-back circuit that limits current

to 35 amps during drag cutting.

2.

ON/OFF Power Switch

ON position supplies AC power to activate all sys-

tem control circuits. OFF position deactivates con-

trol circuits.

SET

RUN

RUN

ON

ON

OFF

OFF

TEMP

TEMP

AC

GAS

GAS

DC

DC

A

120

120

30

30

75

75

50

50

100

100

CURRENT

CURRENT

1

2

3

4

5

6

7

A-02078

Figure 4-2 Control Panel