Operational flap linkage installation – E-flite RV-9 450 ARF User Manual

Page 20

20

E-flite RV-9 450 Assembly Manual

Operational Flap Linkage Installation

Required Parts

Wing assembly

Flap linkage

Clevis (2)

Clevis retainer (2)

Flap control horn (2) Flap servo cover

Servo with hardware 2mm x 5mm machine screw

Transmitter

Fuselage assembly

Flight battery

Speed control or separate receiver battery

Connector backplate

Nylon pushrod connector

2mm x 6mm sheet metal screw (4)

Required tools

Pliers

Phillips screwdriver: #1

Pin drill

Drill bit: 1/16-inch (1.5mm)

Thin CA

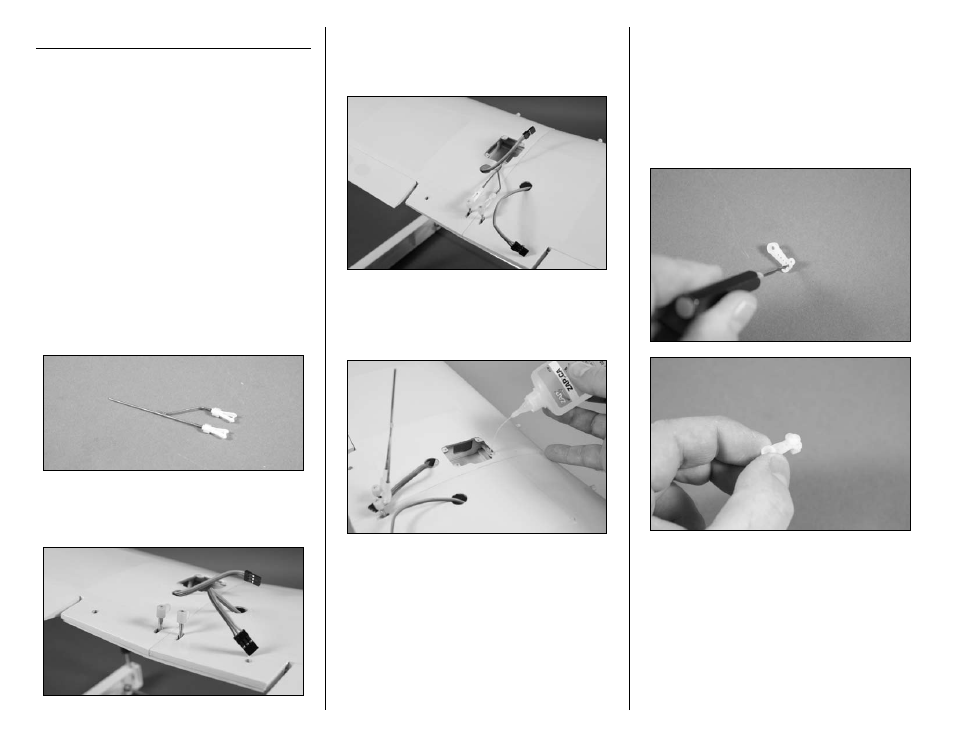

1. Locate two clevises and clevis retainers. Slide the

retainers onto the clevises. Thread the clevises on

the flap linkage 16 turns.

2. Thread the flap control horns on the flap control

rods until the top of the horn is aligned with the top

of the threaded rod.

3. Connect the clevises from the flap linkage to the

flap control horns. Do not slide the clevis retainers

into position as the clevises may require adjustment

to position the flaps properly.

4. Apply 2–3 drops of thin CA into each hole to

harden the surrounding wood. This provides a

harder surface, making the screws more secure

when installed.

5. Use a #00 Phillips screwdriver to remove the

servo horn from the flap servo. Use a pin drill

and 1/16-inch (1.5mm) drill bit to enlarge the

outer hole that is 1/2-inch (13mm) from the center

of the servo horn. Secure the pushrod connector

using a pushrod connector backplate. Insert the

nylon pushrod connector in the hole enlarged in

the last step. Use pliers to press the backplate onto

the connector.