Rope pull emergency stop switches, Rp-ls42f-75l.. series, E-stop reset – Banner RP-LS42 Rope Pull Switches User Manual

Page 7: Maintenance, Repairs

Rope Pull Emergency Stop Switches –

RP-LS42F-75L.. Series

P/N 67709 rev. A

7

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

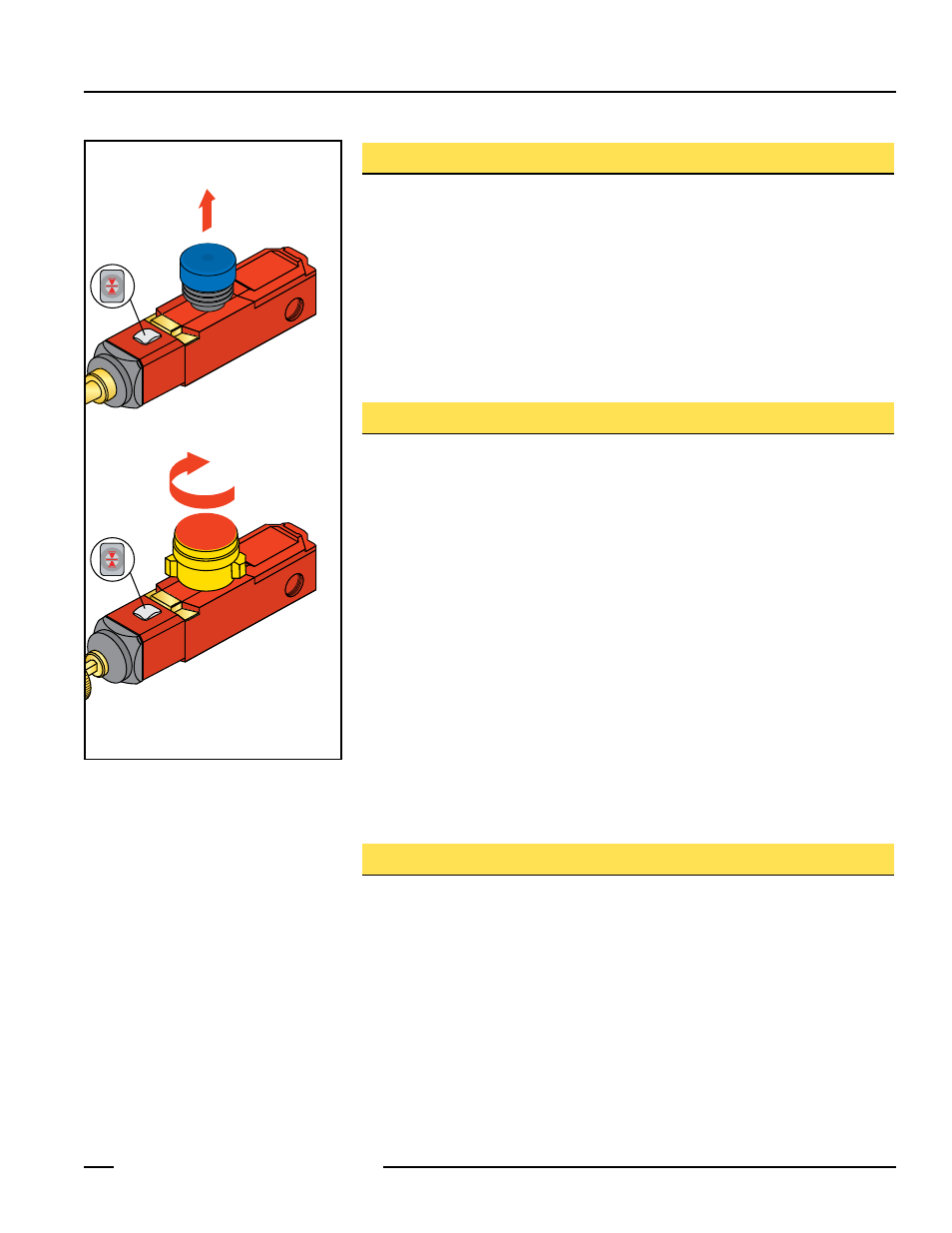

E-Stop Reset

E-Stop and Latch Reset

Following the pulling of the rope or the pressing of the E-stop button (model RP-LS42F-

75LE), the latch must be reset. The procedure differs slightly between the two models.

See Figure 6.

Models RP-LS42F-75L and RP-LS42F-75LF: Pull the blue reset button; the arrows

should then be centered in the tensioning indicator window.

Model RP-LS42F-75LE: The E-stop can be reset only when proper tension is indicated.

Turn the yellow knob clockwise until the blue arrow is in the “I” position (indicating that

the latch has been reset). The latch should make an audible click when reset.

Maintenance

Each rope pull emergency stop installation should be tested for proper machine

shutdown response at each shift change or machine setup by a Designated Person*.

In addition, a Qualified Person* should check for proper rope tension, and adjust as

needed, on a periodic schedule determined by the user, based upon severity of the

operating environment and the frequency of switch actuations.

The pulleys and other moving parts associated with the rope should be periodically

lubricated. If inspection reveals dirt on the rope pull switch or rope assembly, the dirt

must be cleaned off and its cause must be eliminated. Replace the rope pull switch

and/or rope assembly when any parts (including contacts) or assemblies are found to be

damaged, broken, deformed, or badly worn.

The rope pull switch and rope assembly should be replaced at specified intervals based

upon the environment and operating conditions. Replacement of the rope pull switch and

rope assembly should be considered after no more than 500,000 operations. Always

test the control system for proper functioning under machine control conditions after

maintenance or replacement of the rope pull switch.

* A Designated Person is identified in writing by the employer as being appropriately trained to perform

a specified checkout procedure. A Qualified Person possesses a recognized degree or certificate

or has extensive knowledge, training, and experience to be able to solve problems relating to the

emergency stop rope pull switch installation.

Repairs

Banner rope pull emergency stop switches have no field-replaceable components.

Contact the Banner Factory Application Engineering Group at the address or the

numbers listed at the bottom of the back page. They will issue an RMA (Return

Merchandise Authorization) number for your paperwork, and give you the proper shipping

address.

Figure 7. Resetting the latch

Model RP-LS42F-75L

and RP-LS42F-75LF

Model RP-LS42F-75LE

Pull

Turn clockwise

to reset

NOTE: Proper rope tension must

be displayed before latch

can be reset