Rope pull emergency stop switches, Rp-ls42f-75l.. series, Models – Banner RP-LS42 Rope Pull Switches User Manual

Page 3: Overview, Warning

Rope Pull Emergency Stop Switches –

RP-LS42F-75L.. Series

P/N 67709 rev. A

3

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

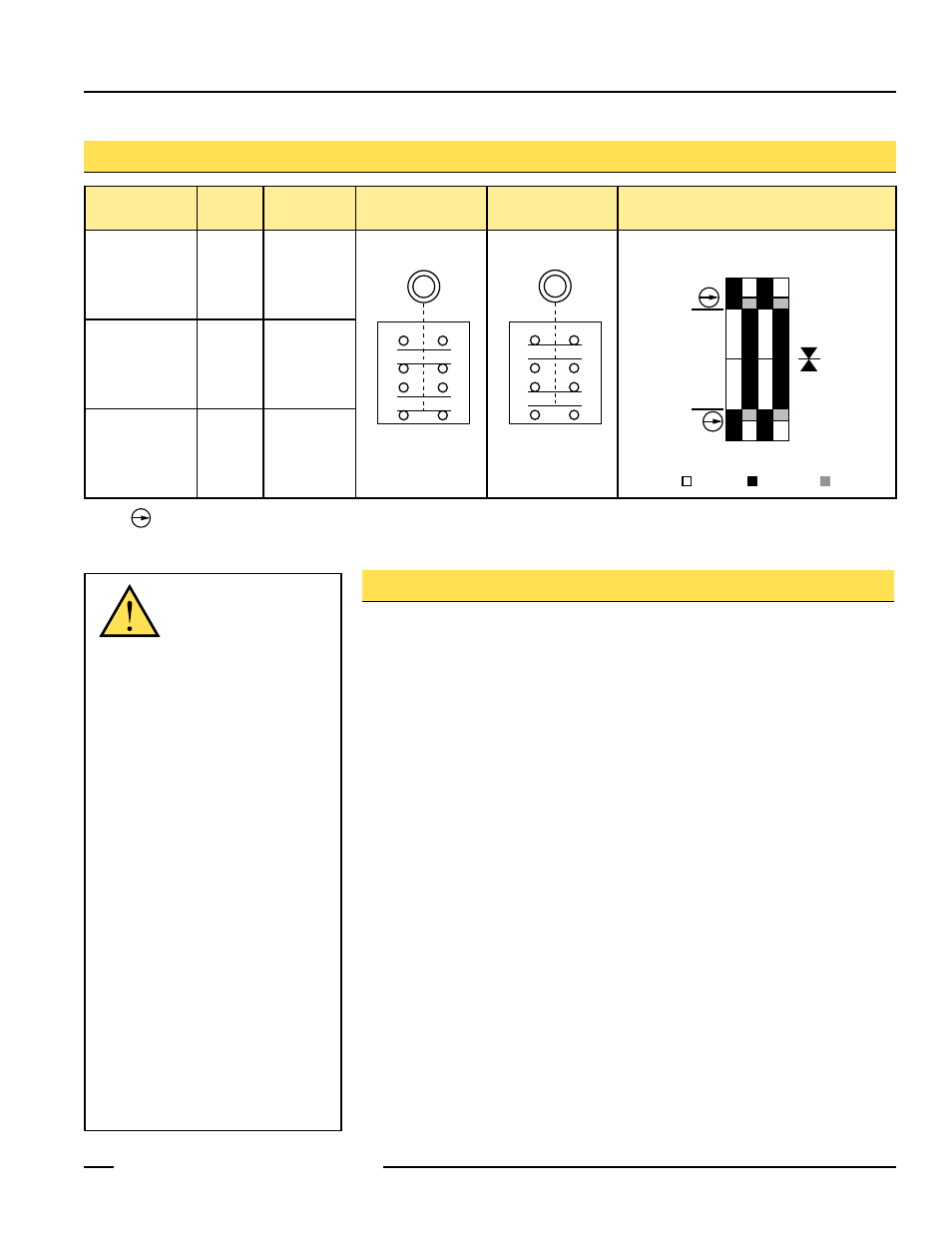

Models

Model

†

E-Stop

Built-in

Turnbuckle

Run

Position

Cable Pulled/

Cable Break

Switching

Diagram

RP-LS42F-75L

No

No

RP-LS42F-75LE

Yes

Yes

RP-LS42F-75LF

No

Yes

21

22

13

14

41

42

33

34

21

22

13

14

41

42

33

34

21

22

13

14

41

42

33

34

21

22

13

14

41

42

33

34

13-14

21-22

Break (180N)

Tension

Set Point

240N

Latch

Pull (300N)

-5 (0.20)

+5 (0.20)

-3.8 (0.15)

-3 (0.12)

+3 (0.12)

mm (in)

+3.8 (0.15)

33-34

41-42

Latch

Overview

Models RP-LS42F-75L.. are rope pull emergency stop switches in compact, limit switch-

style housings made of high-impact thermoplast. When used with steel wire rope, they

can provide emergency stop actuation along conveyors and similar machinery. Red

PVC-covered 3 mm diameter wire rope is recommended (see page 10).

The switches have redundant contacts; terminals 21/22 and 41/42 are positive opening

when there is a cable-pull or cable-brake situation. When used separately, these contacts

provide inputs to a dual-channel safety module (see Figure 6). Terminals 21/22 and

41/42 can also be used individually to provide single-channel switching or as a single-

channel input to a safety module. Terminals 13/14 and 33/34 are for monitoring purposes

only (closed in a cable-brake/-pull situation).

When the rope is properly tensioned (240N), the red arrows are centered on the hash

mark on the tension indicator window, the contacts at terminals 21/22 and 41/42 are

closed, and the contacts at terminals 13/14 and 33/34 are opened (see Figures 1, 2

and 4).

These rope pull emergency stop switches are not generally considered safeguarding

devices, in that they do not prevent or reduce exposure of individuals to a hazard. They

provide the same function as other types of emergency stop switches.

All models feature “latching” operation. When the rope is pulled, the switch contacts

21/22 and 41/42 open and remain open until the built-in reset button is manually reset

(see Figure 1).

WARNING ...

Not a Safeguarding

Device

An Emergency Stop Device, including,

but not limited to buttons, rope pulls and

cable pulls, is not generally considered

a safeguard; and does not alone fulfill

U.S. or International requirements for

safeguarding hazards associated with

machinery.

The definition of safeguarding is the

"protective measure using safeguards [guards

or protective devices] to protect persons from

the hazards which cannot reasonably be

eliminated..." (ISO12100-1, 3.29 and 3.30).

A safeguard limits or eliminates an individual's

exposure to a hazard (examples include

interlocking devices, safety mats, safety light

screens). An emergency stop is considered

to be a complementary protective measure,

which is neither an inherently safe design

measure, nor safeguarding, but may

be required as part of the safety related

control system and risk reduction strategy

(ISO12100-2, 4.5.1 and 4.5.2).

The user must refer to the relevant

standard(s) to determine the safeguarding

requirements for their particular situation.

NOTE:

This symbol for a positive-opening safety contact (IEC 60947-5-1) is used in the switching diagram to identify the point in actuator travel where

the normally-closed safety contact is fully open.

Contacts: Open Closed Transition