Electrical installation, Maintenance/checkout – Banner RP-LM40 Rope Pull Switches User Manual

Page 4

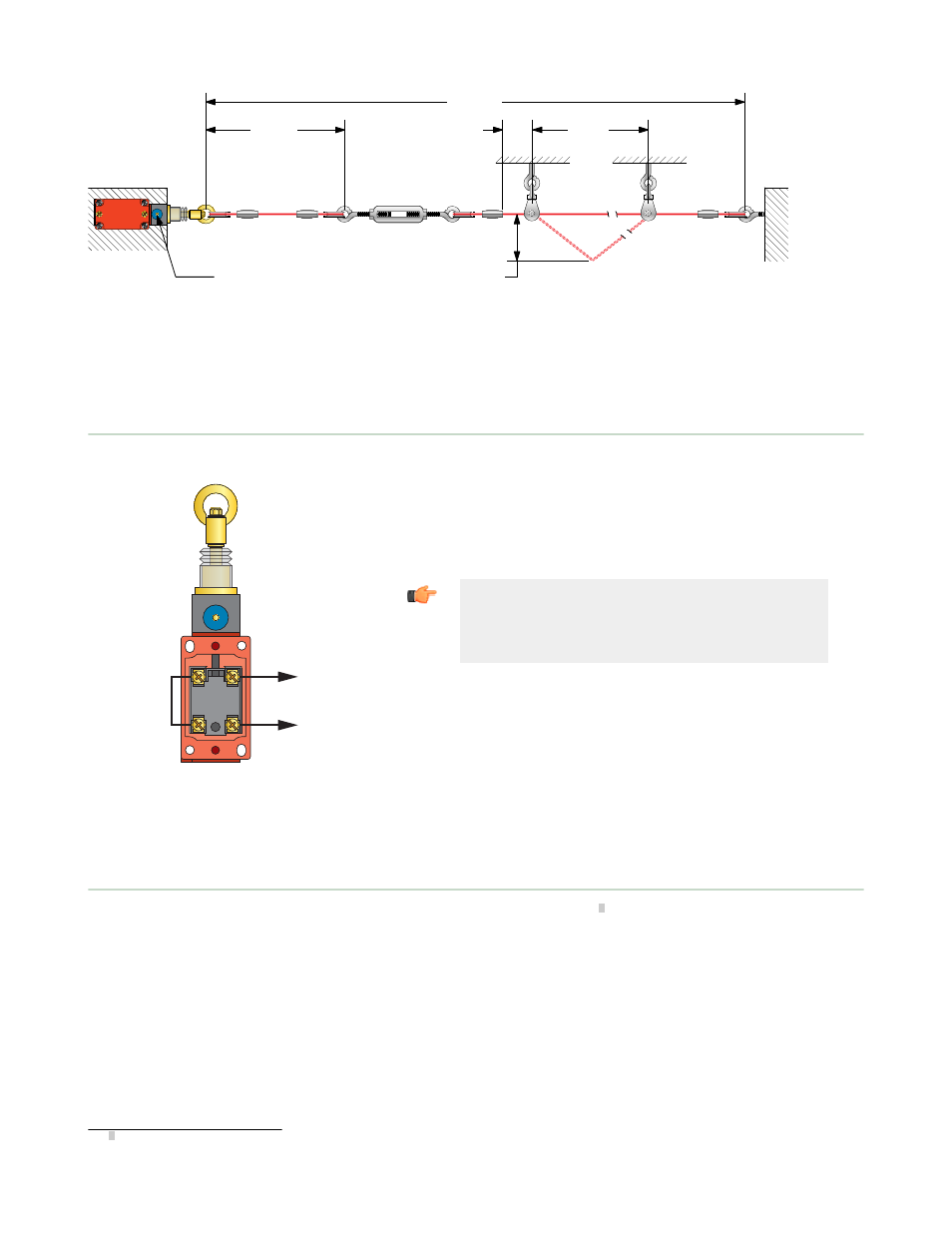

150 mm

(6") max.

6 m

(20') max.

3 m

(10') max.

25 mm

(1") min.

400 mm (16") max.

for Actuation of Switch

NOTE: Force to actuate must not exceed 200 N (45 lbf)

Reset Button—

Pull to Reset

Figure 4. Assembly of Rope and Hardware

All hardware is supplied by the user. The switch mounting holes are on a standard limit switch mounting pattern of 30 x 60

millimeters, and accept M5 (#10) hardware. Wire rope and associated hardware may be ordered separately; see

Accessories.

Electrical Installation

Install

Jumper Wire

Between

Contacts

13

25

14

26

To

Machine

Control

Stop

Circuit

Figure 5. Wire the two switch contacts in series

Access to the Wiring Chamber. The wiring chamber is accessed via a

cover plate (remove two screws). A conduit adapter is supplied to convert

the 20 millimeter threaded entrance to 1/2" NPT. An accessory cable gland

which fits the M20 thread is also available.

Wiring. Install a jumper wire to place the two switch contacts in series, as

shown.

Important: Model RP-LM40D-6 does not latch contacts

25–26 open when the rope is pulled. The contacts close

when the rope is released. When using model RP-

LM40D-6, a latch circuit must be included in the

machine control circuitry.

Maintenance/Checkout

At switch installation or replacement and at machine set up, a Designated Person

1

must test each switch for proper

machine shutdown response and check the switch(es) and installation for proper operation, physical damage, mounting

(looseness), and excessive environmental contamination. This must also take place on a periodic schedule determined by

the user, based on the severity of the operating environment and the frequency of switch actuations. Adjust, repair, or

replace components as needed. If inspection reveals contamination on the switch, thoroughly clean the switch and

eliminate the cause of the contamination. Replace the switch and/or appropriate components when any parts or

assemblies are damaged, broken, deformed, or badly worn; or if the electrical/mechanical specifications (for the

environment and operating conditions) have been exceeded. Always test the control system for proper functioning under

machine control conditions after performing maintenance, replacing the switch, or replacing any component of the switch.

Additional items that should be included in the checkout and/or regularly scheduled maintenance of a rope pull system:

•

Check for proper rope tension and adjust as needed

•

Verify free operation (no binding) of the rope and proper tripping when the rope is pulled

•

Periodically lubricate the pulleys and other moving parts associated with the rope

1 A Designated Person is identified in writing by the employer as being appropriately trained to perform a specified checkout procedure.

RP-LM40 Series Rope Pull Switches

4

www.bannerengineering.com - tel: 763-544-3164

P/N 62082 Rev. C