Mechanical installation – Banner RP-LM40 Rope Pull Switches User Manual

Page 3

WARNING: Not a Safeguarding Device

An Emergency Stop Device is not considered a safeguarding device because it requires an

overt action by an individual to stop machine motion or hazards.

A safeguarding device limits or eliminates an individual's exposure to a hazard without action by the

individual or others. Because an individual must actuate the device for it to function, these devices do

not fit the definition of a safeguarding device and cannot be substituted for required safeguarding. Refer

to the relevant standards to determine those requirements.

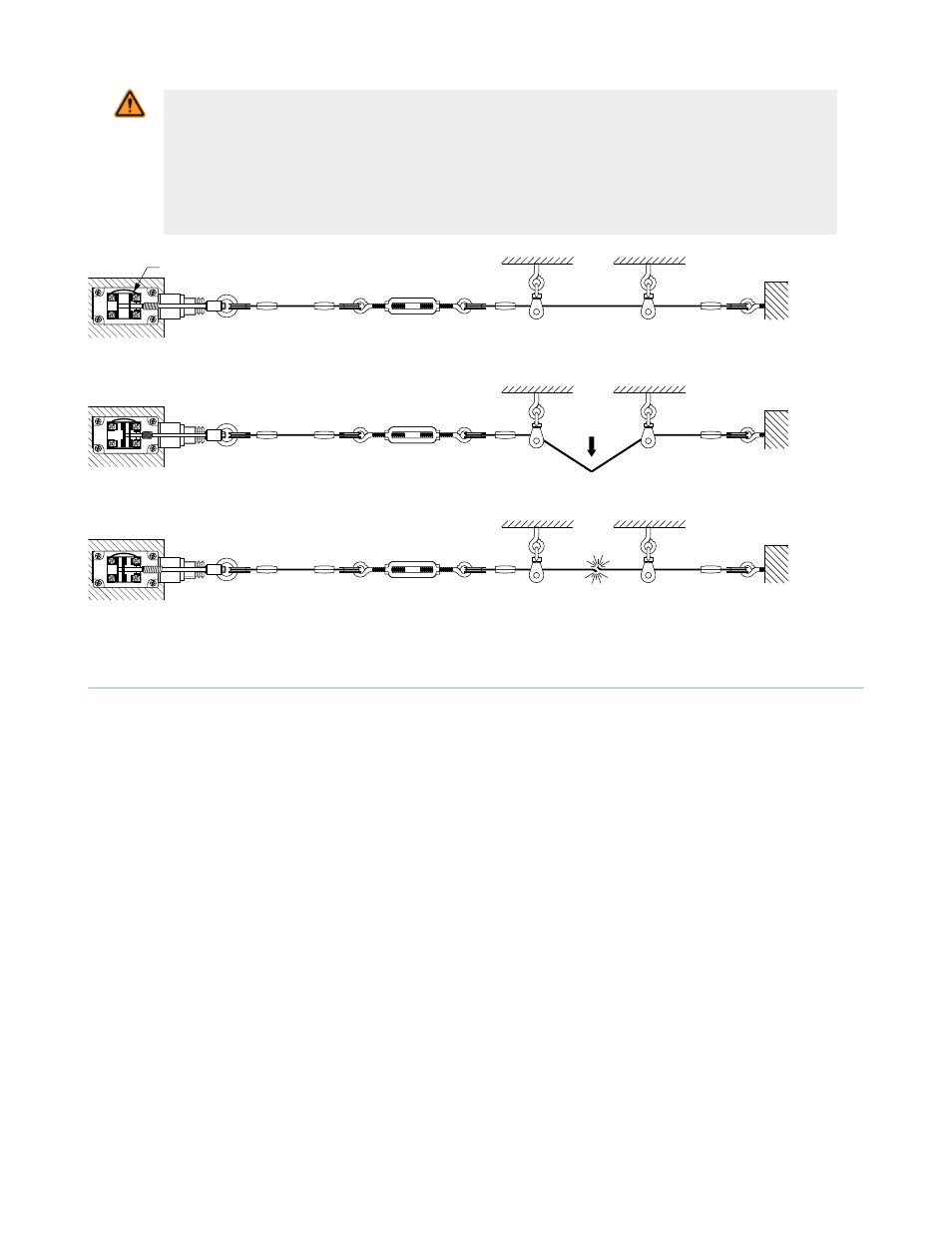

Wire in Series

Figure 1. Run Position: Proper Rope Tension

Figure 2. Rope Pulled: Contact 25-26 Opens

Figure 3. Rope Break or Slack: Contact 13-14 Opens

Mechanical Installation

Installation Guidelines

•

The rope should be easily accessible and visible along its entire length. Markers or flags may be fixed on the rope

to increase its visibility

•

Mounting points, including support points, must be rigid and allow sufficient space around the rope to allow easy

access

•

The rope should be free of friction at all supports. Pulleys are recommended

•

Use only pulleys (not eye bolts) when routing the rope around a corner or whenever direction changes, even

slightly

•

Never run rope through conduit or other tubing

•

Never attach weights to the rope

•

Temperature affects rope tension. The rope expands (lengthens) when temperature increases, and contracts

(shrinks) when temperature decreases. Significant temperature variations require frequent checks of the tension

adjustment

•

Do not exceed the maximum specified total rope length. Banner offers models for other spans; contact Banner

Engineering or visit

www.bannerengineering.com

for model selection

Installation Procedure

1. Mount the switch securely on a solid, stationary surface.

2. Fasten an eye bolt at the opposite end of the rope span, up to 6 m (20 ft) from the switch. The anchor for the eye

bolt also must be solid and stationary, to withstand the constant tension of the rope.

3. Assemble the rope as shown. Keep the rope’s PVC cover intact along its complete length.

4. Use pulleys (recommended) or eye bolts at each support point. A pulley must be used when routing the rope

around a corner, regardless of the angle.

5. Connect a continuity tester (or ohmmeter) between terminals 25–26 of the switch. Adjust the turnbuckle to tighten

the rope, until contact 25–26 closes. This indicates sufficient rope tension.

6. Pull hard on the rope several times. If contact 25–26 remains open (following reset, for model RP-LM40D-6L),

further tighten the turnbuckle, until contact 25–26 closes.

7. Repeat step 6 until contact 25–26 remains closed for the Run condition.

RP-LM40 Series Rope Pull Switches

P/N 62082 Rev. C

www.bannerengineering.com - tel: 763-544-3164

3