Banner QMT72 Rope Pull Switches User Manual

Page 5

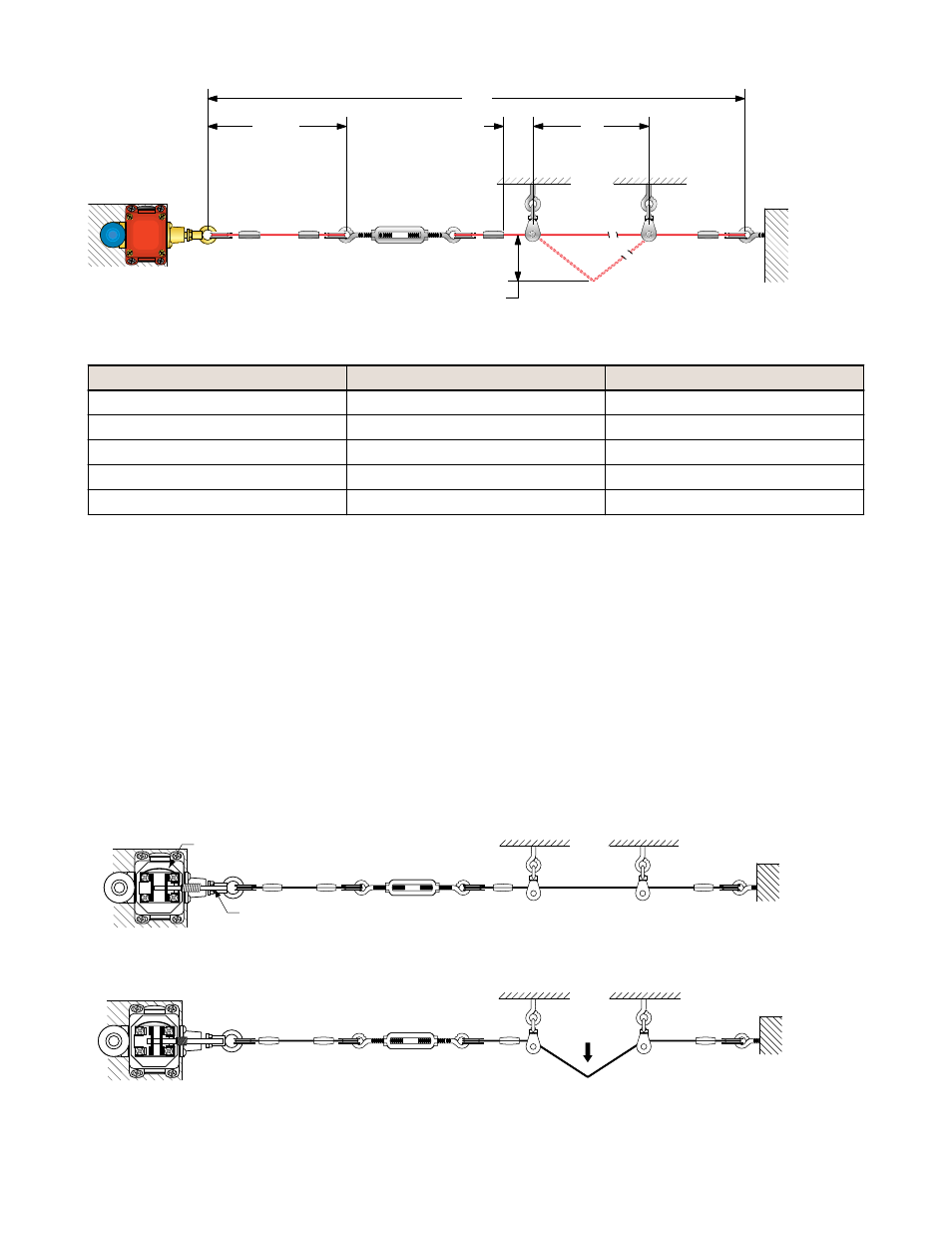

150 mm

(6") max.

L1

L2

25 mm

(1") min.

400 mm (16") max.

for Actuation of Switch

NOTE:

Force to actuate must

not exceed 200 N (45 lbf)

Figure 2. Assembly of Rope and Hardware

Model

Max. Total Length L1

Max. Distance Between Pulleys L2

RP-QM72D-6L

6 m (20 ft)

3 m (10 ft)

RP-QM72D-12L

12 m (40 ft)

4 m (13 ft)

RP-QMT72D-20L

20 m (66 ft)

5 m (17 ft)

RP-QMT72E-12L

12 m (40 ft)

4 m (13 ft)

RP-QMT72F-12L

12 m (40 ft)

4 m (13 ft)

Installation Procedure

1. Mount the switch securely on a solid, stationary surface.

2. Fasten an eye bolt at the opposite end of the rope span, up to 6 m (20 ft), or 12 m (40 ft) or 20 m (66 ft) from the

switch, depending on model. The anchor for the eye bolt also must be solid and stationary, to withstand the

constant tension of the rope.

3. Assemble the rope, as shown. Keep the rope’s PVC cover intact along its complete length.

4. Use pulleys (recommended) or eye bolts at each support point. A pulley must be used when routing the rope

around a corner, regardless of the angle.

5. Apply tension to the rope using the turnbuckle until the indicator mark on the switch aligns with the leading edge of

the housing flange. This indicates sufficient rope tension. (Contacts 25/26, and 45/46, if applicable, will close.)

6. Pull hard on the rope and reset the latch several times. If contact 25/26 (45/46) remains open following the reset,

further tighten the turnbuckle, until contact 25/26 (45/46) closes.

7. Repeat step 6 until contact 25/26 (45/46) remains closed for the Run condition.

All hardware is supplied by the user. The switch mounting holes are on a mounting pattern of 72 x 40 or 72 x 76

millimeters, and accept M5 (#10) hardware. Wire rope and associated hardware may be ordered separately; see

Accessories.

Wire in Series

Tension Indicator Mark

Figure 3. Run Position: Proper Rope Tension

Figure 4. Rope Pulled: Contact 25/26 (45/46) Opens

Rope Pull Switches

P/N 62084 Rev. C

www.bannerengineering.com - tel: 763-544-3164

5