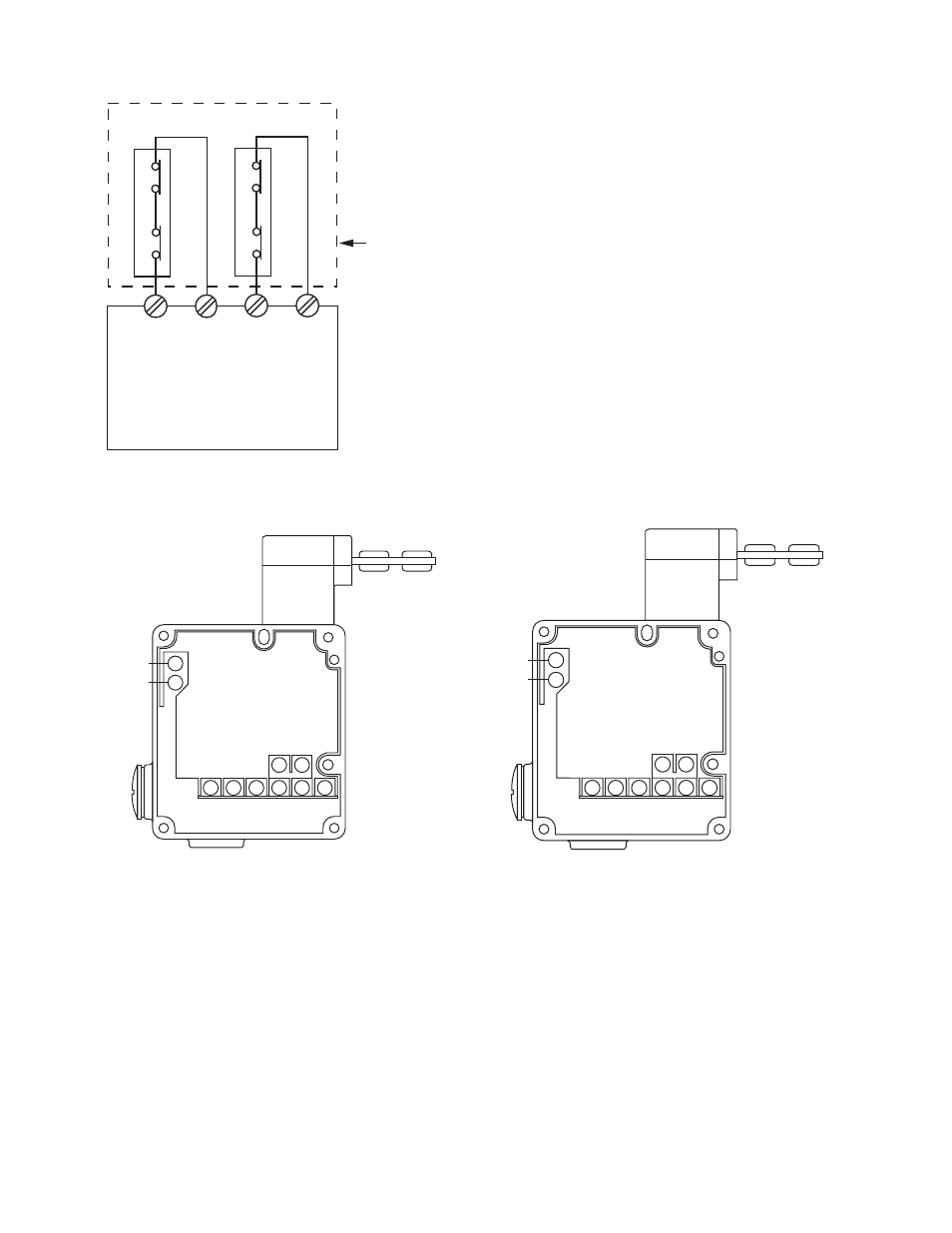

Figure 1. switch wiring to safety module, Figure 3. switch electrical connec, Tions for si-gm100xdsh models – Banner SI-QM100 Locking Style Switches User Manual

Page 5: Periodic checks

Safety Switch #1

Safety Switch #2

Input

Channel

#1

Input

Channel

#2

2-channel Safety Module

(2-channel E-stop Module

2-channel Gate Monitor Module, etc.)

Single gate

or guard

32

21

22

31

32

21

22

31

Figure 1. Switch Wiring to Safety Module

Refer to the installation instructions provided with the safety mod-

ule for information regarding the interface of the safety module to

the machine stop control elements.

Connect two redundant safety switches per interlock guard to an

appropriate 2-channel input safety module.

13

E1

E2

14

21

22

31

43

44

32

Solenoid

Voltage

Figure 2. Switch Electrical Connections for SI-GM100xG Mod-

els

11

E1

E2

12

21

22

31

43

44

32

Solenoid

Voltage

Figure 3. Switch Electrical Connections for SI-GM100xDSH

Models

Periodic Checks

Safety switches should be checked at each shift change or machine setup by a designated person for:

1. Breakage of the switch body or actuator,

2. Good alignment and full engagement of the actuator with the receptor,

3. Confirmation that the safety switch is not being used as an end stop,

4. Loosening of the switch or actuator mounting hardware, and

5. Verification that it is not possible to reach any hazard point through an opened guard (or any opening) before hazardous machine

motion has completely stopped.

In addition, a qualified person should check for the following on a periodic schedule determined by the user based upon the severity of

the operating environment and the frequency of switch actuations:

Machine Safety Switches

P/N 049374 Rev. F

www.bannerengineering.com - tel: 763-544-3164

5