Optical alignment, Dy, perform the – Banner EZ-SCREEN Safety Light Curtain Systems User Manual

Page 31

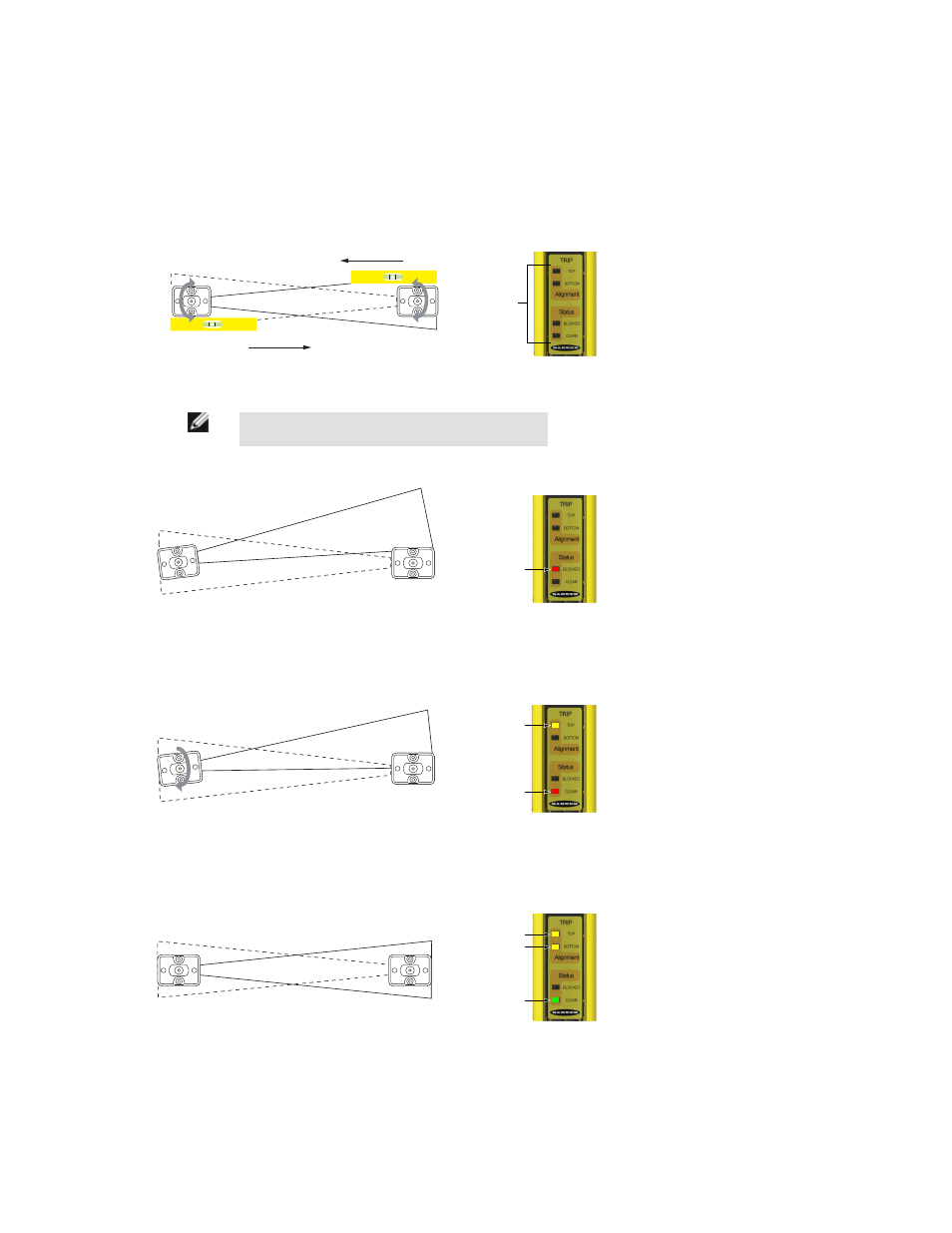

Optical Alignment

1. Verify sensor mounting.

2. Verify optimal alignment, adjusting sensor rotation with power ON:

a. Verify that the emitter and receiver are pointed squarely at each other. Use a straight edge (for example, a level) to deter-

mine the direction the sensor is facing. The sensor face must be perpendicular to the optical axis.

Straight Edge

Straight Edge

All OFF

NOTE: At power-up, all indicators are tested (flash).

b. If the synchronization beam is not aligned, the Status Blocked indicator is Red and both Alignment indicators will be OFF.

ON Red

c. If the Green Status and Yellow Alignment indicators are ON, go to step “d”. If not, rotate each sensor (one at a time) left and

right until the Status Clear indicator comes ON Green. As the sensor rotates out of alignment, the Status Blocked indicator

will come ON Red.

ON Red

ON Yellow

d. To optimize alignment, note the position where the Status Blocked indicator comes ON Red when the sensor is rotated both

left and right. Center the sensor between the two positions, and tighten the end cap mounting screws, making sure the posi-

tioning does not drift as the screws are tightened.

ON Green

ON Yellow

ON Yellow

For situations where alignment is difficult, a LAT-1-LS Laser Alignment Tool can be used to assist or confirm alignment by

providing a visible red dot along the sensor’s optical axis.

EZ-SCREEN® Type 2 Light Screen Instruction Manual

122452 rev. B

www.bannerengineering.com - tel: 763-544-3164

31