Rockwell Automation FlexPak Plus NRG DC Drive User Manual

Page 9

8

SECTION 3

INSTALLATION

3.0 General

- This Section outlines the procedures

that are to be followed in order to properly install a FlexĆ

Pak Plus controller.

The dĆc motor should be installed and wired in accorĆ

dance with installation instructions supplied with each

drive.

There are certain general warnings and cautions that

should be kept in mind before planning begins. They

should be considered a general checklist which, iffolĆ

lowed, will minimize installation problems and decrease

assembly time. As a user aid, they are listed here.

DANGER

THIS UNIT SHOULD BE INSTALLED, ADJUSTED

AND SERVICED BY QUALIFIED ELECTRICAL

MAINTENANCE PERSONNEL FAMILIAR WITH

THE CONSTRUCTION AND OPERATION OF

THIS TYPE OF EQUIPMENT. THEY SHOULD

ALSO BE FAMILIARWITH THE POTENTIAL

HAZARDS INVOLVED. IF THIS WARNING IS NOT

OBSERVED. PERSONAL INJURY OR EQUIPĆ

MENT DAMAGE MAY RESULT.

DANGER

BE ABSOLUTELY CERTAIN THAT A GROUND

WIRE FROM THE INCOMING AĆC POWER LINE

IS PROPERLY CONNECTED TO THE CHASSIS

GROUND TERMINAL PROVIDED. WITHOUT

PROPER GROUNDING, PERSONAL INJURY

MAY OCCUR.

WARNING

THE CONTROLLER REQUIRES A THREEĆ

PHASE POWERSUPPLY THAT PROVIDES EIĆ

THER230 VAC OR460 VAC AT 60 HZ, OR220

VAC OR 440 VAC AT 50 HZ. IF CORRECT

VOLTAGE IS NOT AVAILABLE, IT WILL BE

NECESSARY TO INSTALL A TRANSFORMER

BETWEEN THE POWERSUPPLY AND THE

CONTROLLER. DO NOT OPERATE THE FLEXĆ

PAK PLUS CONTROLLERON POWERSUPĆ

PLIES WITH AVAILABLE SHORTĆCIRCUIT CURĆ

RENTS IN EXCESS OF 5000 AMPERES. DAMĆ

AGE TO EQUIPMENT AND PERSONAL INJURY

MAY OCCUR.

WARNING

THE USERIS RESPONSIBLE FORCONFORMĆ

ING WITH THE NATIONAL ELECTRICAL CODE

WITH RESPECT TO MOTOR, CONTROLLER

AND OPERATOR DEVICE INSTALLATION, WIRĆ

ING AND STARTĆUP. THE USER IS ALSO REĆ

SPONSIBLE FORUNDERSTANDING AND APĆ

PLYING ALL OTHERAPPLICABLE LOCAL

CODES WHICH GOVERN SUCH PRACTICES AS

WIRING PROTECTION, GROUNDING, DISCONĆ

NECTS AND OVERCURRENT PROTECTION.

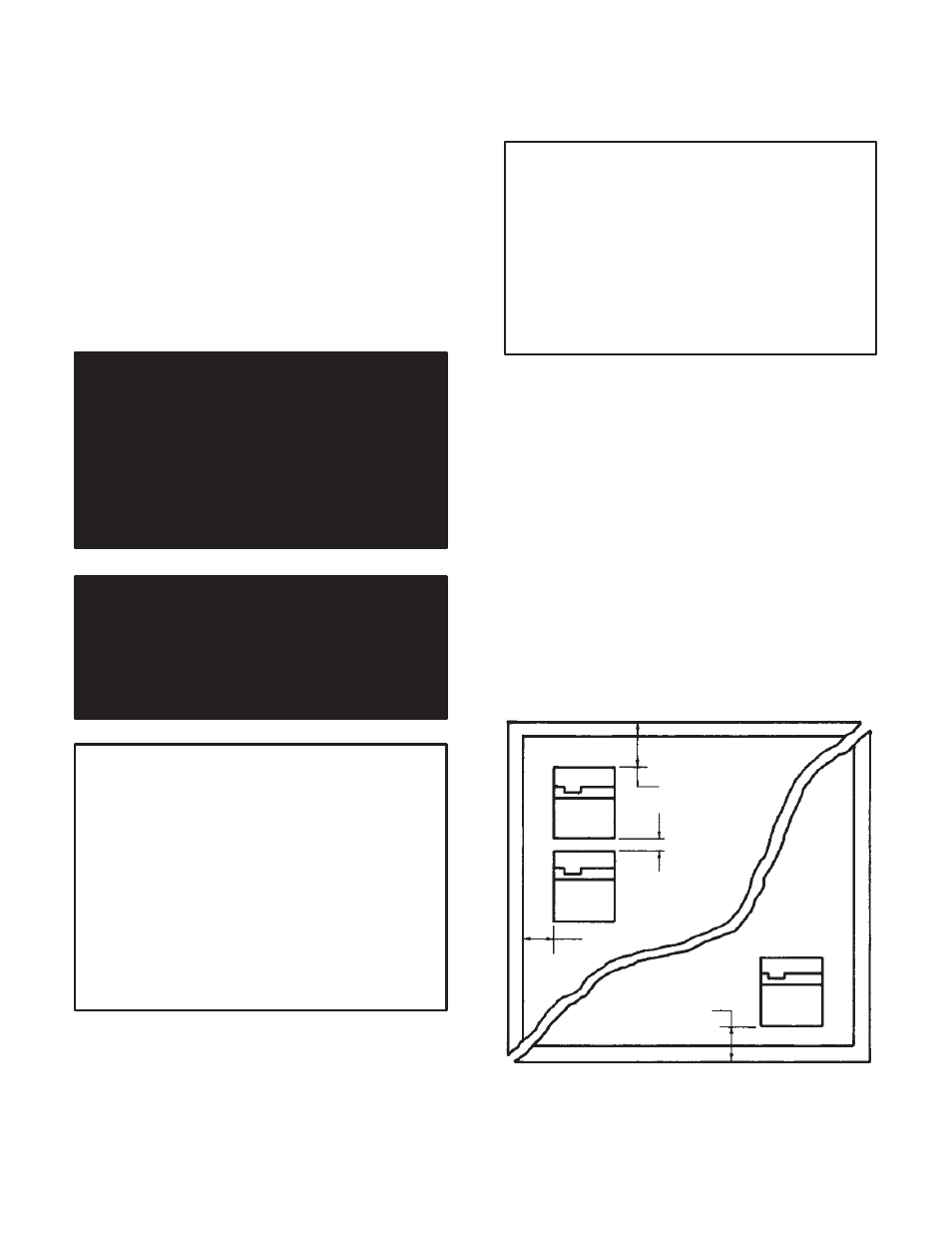

3.1 Layout Guidelines

- This Paragraph lists recĆ

ommended layout procedures common to all FlexPak

Plus controllers.

Guideline 1 - The FlexPak Plus controller is designed

as a panelĆmounted unit. It is to be hung within 10S of

vertical with the rear ofthe Chassis firmly resting against

the mounting surface. (Do not position the Chassis on

a horizontal surface.)

Guideline 2 - It is necessary to leave at least a 4 inch

(102 mm) clearance between controllers including top,

bottom and side. This unobstructed area allows for

proper air circulation through the heat sink. Do not

place the controller directly in a corner. Leave at least 8

inches (200 mm) from the top or 6 inches (150 mm) from

the bottom ofthe enclosure. (Refer to Figure 3.1.) Heat

builds up at the cabinet's top and may exceed the perĆ

missible inside ambient temperature upper limit. At the

cabinet's bottom, the unit must be high enough to allow

air to flow upwards.

8 in. (200 mm)

4 in. (102 mm)

4 in.

(102 mm)

6 in. (150 mm)

Figure 3.1 - Enclosure Mounting Minimum

Distances