Rockwell Automation FlexPak Plus NRG DC Drive User Manual

Page 13

12

WARNING

IN THE OPTIONAL BASIC DRIVE, THE USER

MUST INSTALL AN M CONTACTOR THAT HAS

A 115 VAC COIL WITH A MAXIMUM CURRENT

DRAW OF 440 MILLIAMPS. THE CONTACTOR

ADAPTER KIT MUST BE INSTALLED WITH THE

USER'S M CONTACTOR. (REFER TO DĆ3955)

PERSONAL INJURY MAY OCCUR IF THIS IS

NOT INSTALLED.

All interconnecting wire should primarily be sized and

installed in conformance with N.E.C., C.E.C. or local

codes. Refer to the controller and motor nameplates for

electrical data. Note that long cable runs may require

that a larger gauge be used to avoid excessive voltage

drop. Use of stranded wire, up to 19 strand, is also recĆ

ommended. Wire according to Figure 3.4.

After wiring, examine all terminals to determine that conĆ

nections are correctly made at both ends. Confirm wire

identification. Examine the firmness of the connections.

For applications using the 230V, 3Ć10 HPFlexPak Plus,

wires to the motor armature (A1 and A2) must be lugged

with the provided lugs, or equivalent, before connection

to the appropriate relay terminals.

WARNING

DO NOT ALLOW CONDUCTORS TO GROUND

ON THE CHASSIS. CHECK INTEGRITY OF ALL

WIRE INSULATION BEFORE DRAWING. REĆ

MOVE ONLY ENOUGH INSULATION TO MAKE A

FIRM TERMINAL CONNECTION. PERSONAL

INJURY COULD RESULT IF A BARE WIRE

TOUCHES THE CHASSIS.

3.4 Isolation Transformers

- Although an autoĆ

transformer may be required because of aĆc line voltage

levels, it is unable to provide a number of benefits stanĆ

dard with an isolation transformer.

The general requirements for an isolation transformer

are:

D Three phase

D 3 to 8% impedance

D Nonregulated

D Sinusoidal output

D 50/60 Hz, as required

D 150% overload for 1 minute (max.)

Refer also to Table 2.D for specific information on transĆ

former sizing requirements. In the Transformer" colĆ

umn at the right, maximum kVA and rated kVA figures

are listed in relation to specific dĆc motor hp/ VAC ratĆ

ings.

Reliance Electric offers a number of isolation transformĆ

ers suitable for use with the FlexPak Plus controller.

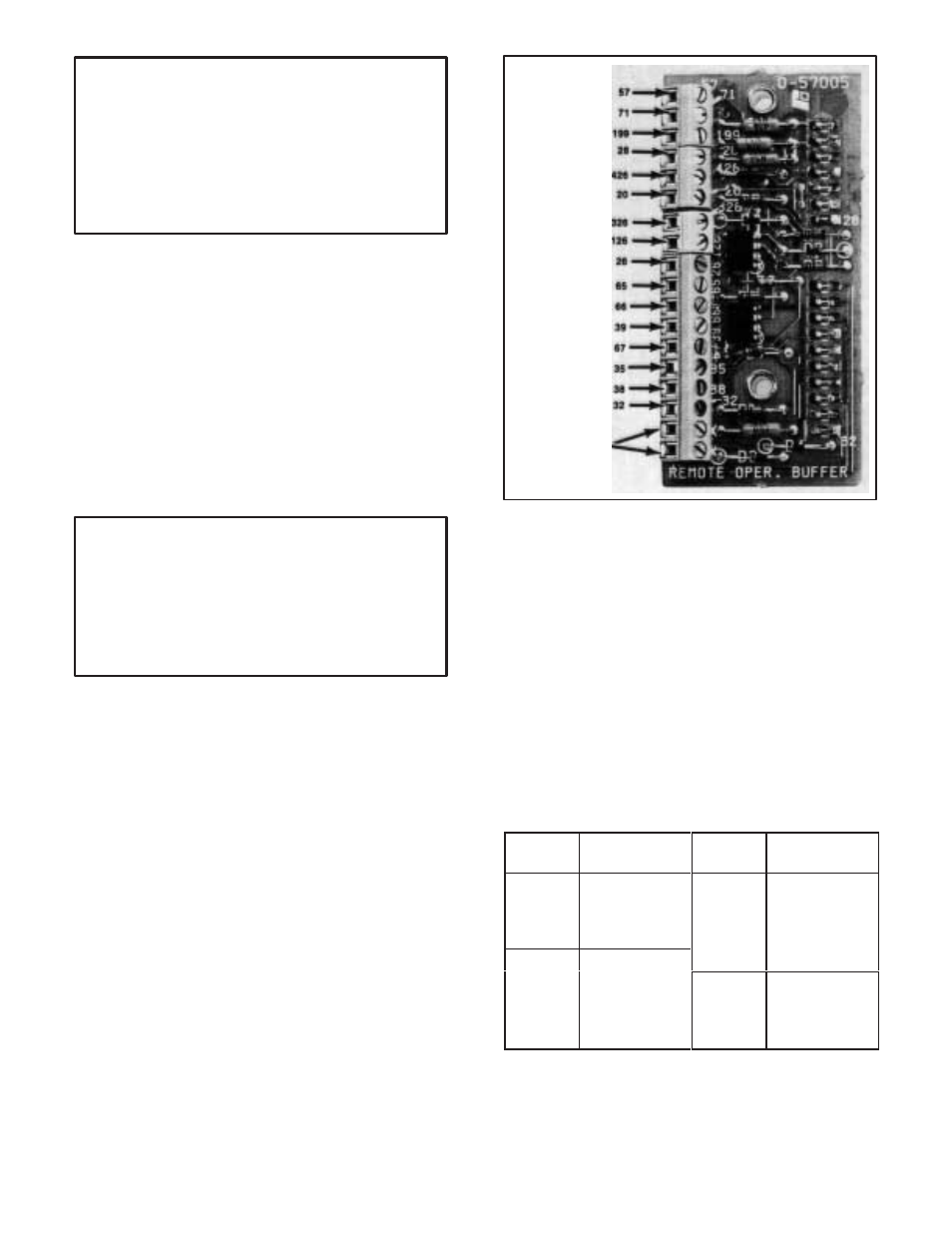

USER

CONVENIENCE,

BLANK

TERMINALS

Figure 3.5 - Remote Operators Buffer Terminal

Markings

3.5 HP/Current Jumper

- It is necessary to inĆ

spect the Current Scaling/Horsepower Jumper on the

Regulator Module to be sure that it is connected correctĆ

ly for a specific drive motor.

Step 1 - On the drive motor, locate the nameplate. Note

the fullĆload current.

Step 2 - Or, if current is not shown on the nameplate,

refer to Table 3.A. Relate the columns in the table with

known motor data. Read across to the right column

marked Motor Current." This figure indicates the propĆ

er jumper connection to make on the Module where a

corresponding number is etched.

Table 3.A - Horsepower Calibration

230 VAC

HP

Motor Current

Pin Connection

460 VAC

HP

Motor Current

Pin Connection

3

5

7.5

13

19

27

3

5

7.5

10

5.7

10

13

19

➀

10

36

15

27

15

20

54

72

20

➀

25

30

40

36

45

54

72

➀

High HPunits cannot be directly scaled to the lower HPunits, above

line, due to current transformers ratios used in feedback loop