Rockwell Automation FlexPak Plus NRG DC Drive User Manual

Page 10

9

Guideline 3 - Regardless of the above placement

guidelines, the user is responsible for providing ambiĆ

ent temperatures that meet the controllers specificaĆ

tions of 0

°

to 55

°

C (32

°

to 131

°

F). This must be given

careful consideration especially to units located near

the very top of the supplied enclosure. Relative humidity

must be kept between 5 and 95% without condensaĆ

tion.

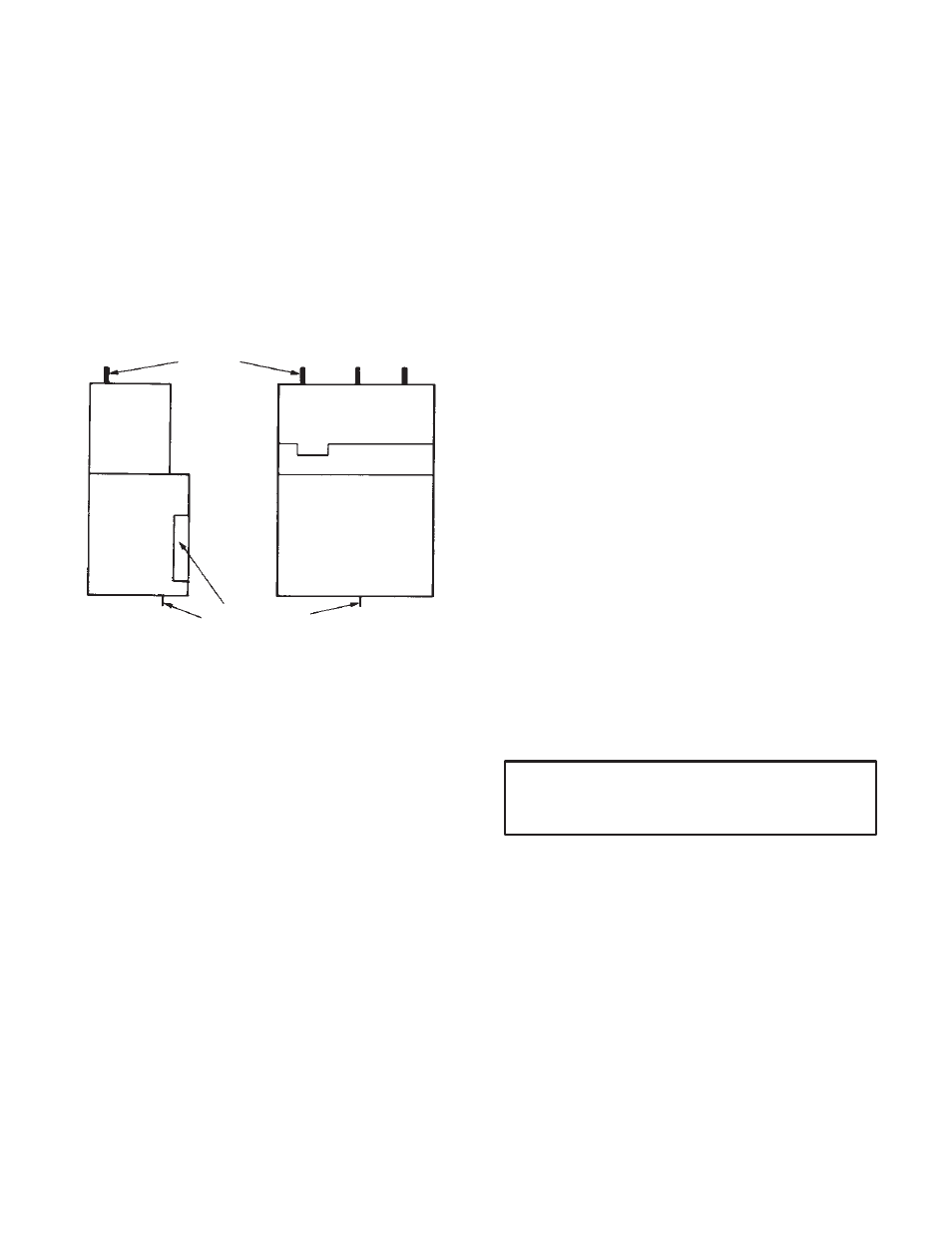

Guideline 4 - Due to the UĆshaped panel design of the

FlexPak Plus, the controller must be mounted in the verĆ

tical position to allow for proper cooling.

The controller is also designed to allow for power wiring

to enter from the top and for control and signal wiring to

be routed in thru the openings in the sides of the controlĆ

ler or from the bottom. (Refer to Figure 3.2.)

POWER

WIRING

CONTROL AND

SIGNAL WIRING

LEFT SIDE VIEW

FRONT VIEW

Figure 3.2 - Mounting and Wiring Orientations

Guideline 5 - Do not route the tachometer feedback

signal cable, if used, with aĆc or dĆc control or power wirĆ

ing. Also use the specified wire for this function..

Guideline 6 - Although autoĆtransformers may step up

and step down aĆc power supply voltage, they do not

isolate the driven system from the aĆc line. Users should

consider using an isolation transformer if the applicaĆ

tion conditions warrant it.

If an isolation or autoĆtransformer is used ahead of the

controller, the disconnect switch should be placed on

the aĆc power line between the power source and the

transformer primary. Again, use a f used disconnect

switch. (Do not use a circuit breaker type switch beĆ

cause of the high inrush of transformer equipment.).

An isolation transformer is not necessary unless the apĆ

plication conditions require one. However, its use proĆ

vides distinct advantages. With an isolation transformĆ

er:

D Personal injury is guarded against should accidental

contact be made with an electrical conductor from

the drive.

D AĆc power line disturbances, or transients, are

minimized by an isolation transformer, thereby reĆ

ducing or eliminating damage to other solidĆstate

equipment powerĆconversion components in the

controller and other userĆequipment on the same ac

line.

D The transformer provides electrical isolation beĆ

tween the aĆc power lines and the drive motor.

Damaging currents may be eliminated in instances

where a dĆc output accidentally becomes grounded

in a unit where the aĆc electrical system is grounded.

For detailed information, refer to Paragraph 3.4.

Guideline 7 - The National Electrical Code requires

that a threeĆpole, fused disconnect switch be installed

on the incoming aĆc line ahead of the controller to proĆ

vide branch circuit protection. The fuse should be Class

K5.

It is recommended that the disconnect switch be placed

within easy reach of operating and maintenance perĆ

sonnel. Do not place it inside a surrounding enclosure

since cabinet doors may be locked. (Consult your local

codes.)

Guideline 8 - It is necessary to connect the GND

(Green/ground) wire of the threeĆconductor incoming

aĆc line to the terminal provided on the Chassis. Ring

type connectors are recommended. The user must be

sure that the ground wire is connected to the plant

ground at the source.

The motor frame should also be grounded. In many

cases it is adequate to use a screw in the conduit box

near the motor.

Guideline 9 - A thermostat is used to guard against

motor overload protection, It is essential to properly

connect the motor thermostat to connections 34 and

132.

CAUTION: External overload devices must be conĆ

nected between terminals 32, 33, 34 and 132. The

drive will not start without them.

Refer to Figure 3.4 where a typical Operator's Station

schematic is shown.

Guideline 10 - When planning signal or control wire

runs, follow these practices:

D Conduits should be steel.

D If these conduits cross 460 VAC conductors, make

sure the cross is at 90

°

.

D Do not route signal wires through junctions or

terminal boxes that contain nonĆsignal aĆc or dĆc

(115/230/460V) wires.