Rockwell Automation FlexPak Plus NRG DC Drive User Manual

Page 20

19

5.3 Motor Problems

- Do not overlook the possiĆ

bility that the malfunction may be located in the drive

motor. The following steps should become part of a

troubleshooting routine:

D Recheck all motor connections for firmness and

correct identification.

D Check that no obvious grounds have occurred on

any of the wires. However, do not use a megger

when checking for grounds unless the motor wiring

to the FlexPak Plus controller is completely disconĆ

nected.

D A voltĆohmmeter (VOM) may be used for ground

checking without disconnecting conductors to the

FlexPak Plus controller.

D Check the field windings for open or short conditions.

D Check continuity through the armature and brushes.

Use terminals A1 and A2 at the Controller as test

points.

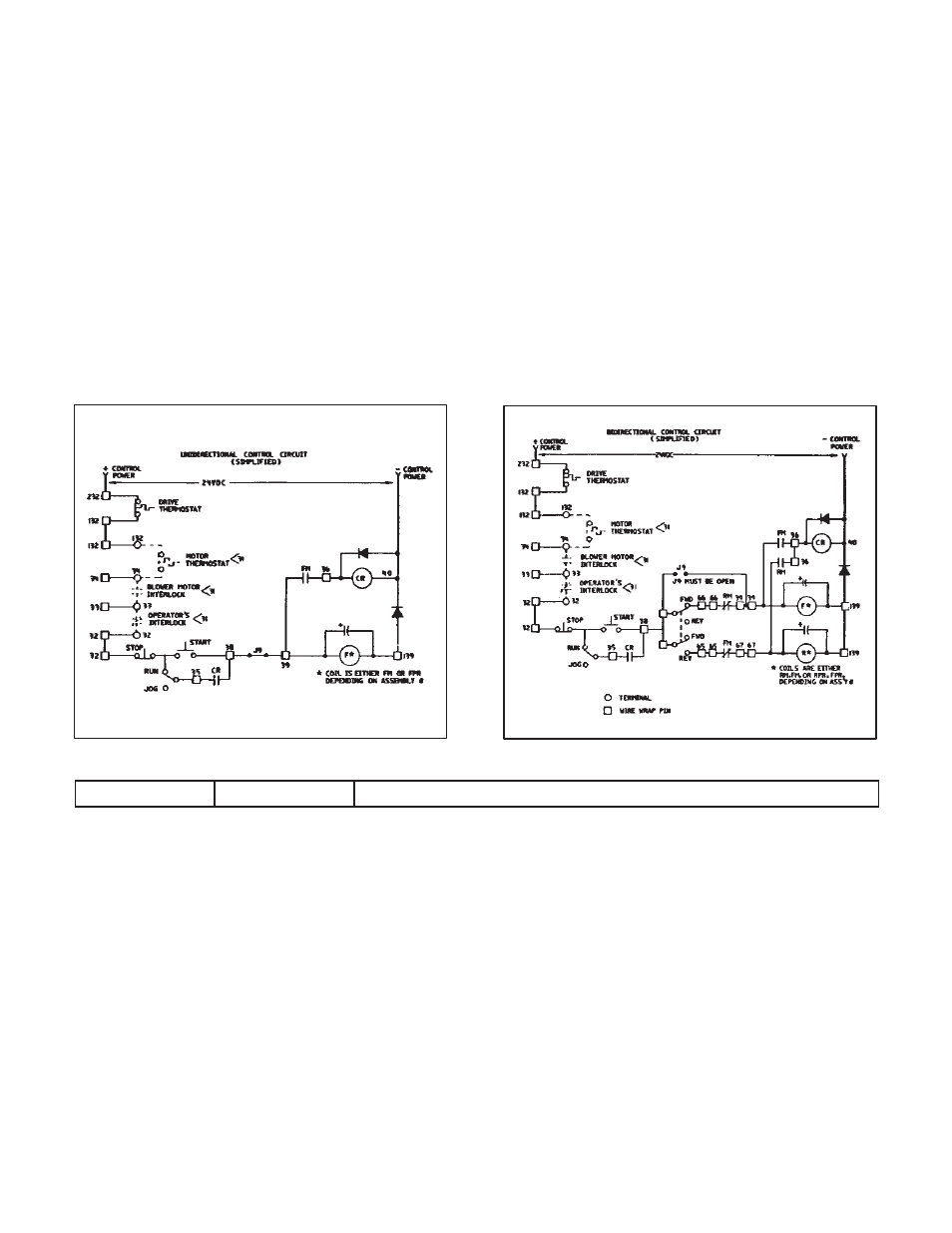

Figure 5.1 - Unidirectional Control Circuit

(simplified)

5.4 Mechanical

- It may be that the malfunction is

a simple mechanical problem. The load on the drive

motor may be too large, or it may have too high an inerĆ

tia. The results are long stopping times and currentĆlimit

starting demands. Thus, the freedom of motion of the

load device should be considered.

5.5 Controller Malfunctions

- Table 5.A presĆ

ents an organized troubleshooting sequence based on

a symptom/probable cause/suggested procedure apĆ

proach. They develop from the most simple, obvious

malfunction to more complex ones.

5.6 Schematics, Diagrams

- In order to aid with

the troubleshooting process, various schematics and

diagrams are included. Note that these drawings are the

latest revisions as of the date of publication of this

manual. The manufacturer cannot guarantee that subĆ

sequent changes will not occur; although, if any do,

they should be minor. In cases of doubt, contact your loĆ

cal Reliance Electric Sales Office.

Figure 5.2 - Bidirectional Control Circuit

(simplified)

Symptom

Probable Cause

Recommended Procedures