Preface – Rockwell Automation Ethernet Design Considerations Reference Manual User Manual

Page 9

Rockwell Automation Publication ENET-RM002C-EN-P - May 2013

9

Preface

Rockwell Automation uses open network technology for seamless, plant-wide

integration. These open networks share a universal set of communication

services. As a result, information can be communicated seamlessly throughout

the plant and to and from the Internet for e-business applications.

Each Rockwell Automation network is ideal for a wide range of applications,

operates with devices manufactured by various vendors, and shares data with

industry-standard information networks.

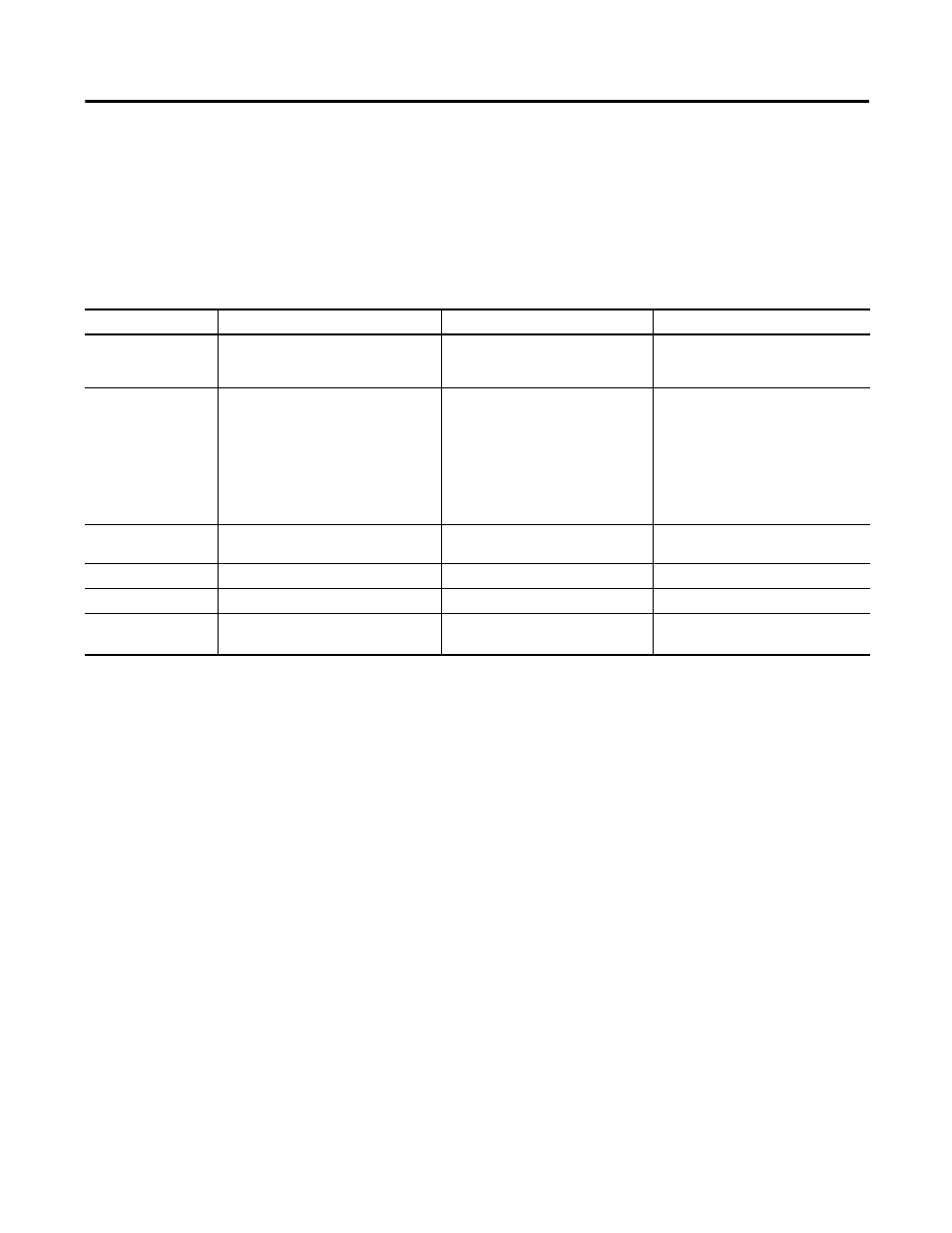

Comparison

EtherNet/IP Network

ControlNet Network

DeviceNet Network

Function

Plant management system tie-in (material

handling) with configuration, data collection,

and control on a single high-speed network

Supports transmission of time critical data

between PLC processors and I/O devices

Connects low-level devices directly to

plant-floor controllers without the use of I/O

modules

Typical devices networked

• Mainframe computers

• Programmable controllers

• Robots

• HMI

• I/O

• Drives

• Process instruments

• Programmable controllers

• I/O chassis

• HMIs

• Personal computers

• Drives

• Robots

• Sensors

• Motor starters

• Drives

• Personal computers

• Push buttons

• Low-end HMIs

• Bar code readers

• PLC processors

• Valve manifolds

Data repetition

Large packets, data sent regularly

Medium-size packets; data transmissions are

deterministic and repeatable

Small packets; data sent as needed

Number of nodes, max

No limit

99 nodes

64 total nodes

Data transfer rate

10 Mbps, 100 Mbps, or 1 Gbps

5 Mbps

500, 250, or 125 Kbps

Typical use

Plant-wide architecture

High-speed applications

Redundant applications

Scheduled communication

Supply power and connectivity to low-level

devices