Rockwell Automation RECOMM-PBUS PROFIBUS Communications Module User Manual

Page 59

Using I/O Messaging

6-7

Parameter Settings

Scanner Settings

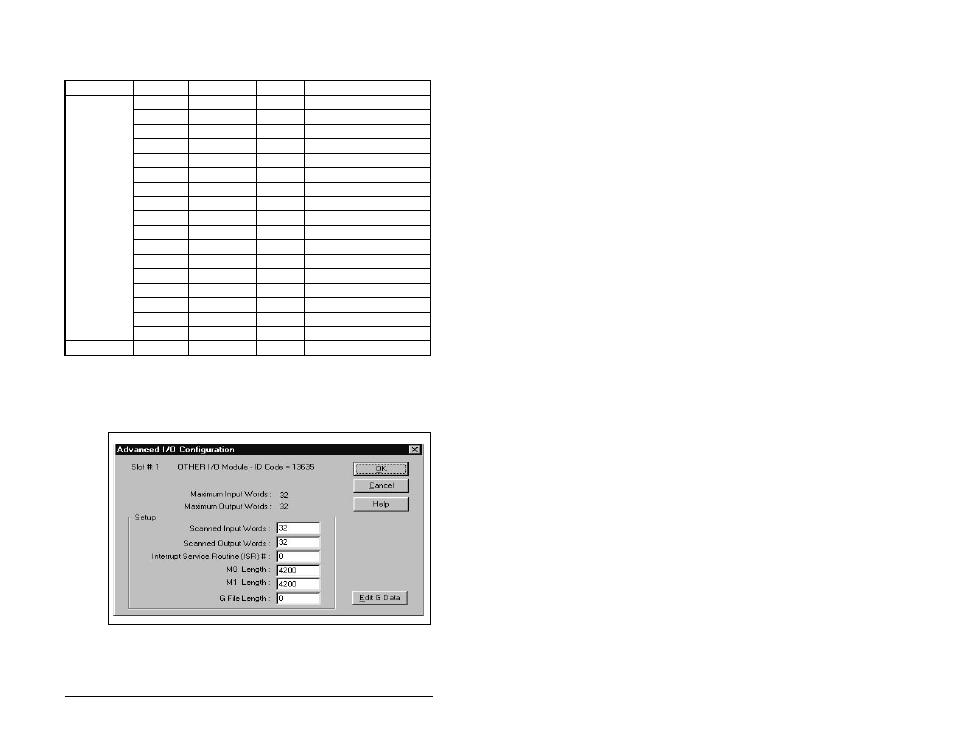

An SST-PFB-SLC scanner is in slot 1 of the SLC rack and

configured as Station 0. The Advanced I/O Configuration is set up

as shown in figure 6.3.

The two PROFIBUS modules are set up as Station 1 and Station 2,

and are configured as 14 words input & output each. See chapter 5.

Table 6.1 – Parameter Settings for Sample SLC Program

Device

Parameter

Name

Value

Description

SP600

90

Speed Ref A Sel

22

‘DPI Port 5’ (RECOMM-PBUS)

300

Data In A1

140

Points to Accel Time 1 (140)

301

Data In A2

142

Points to Decel Time 1 (142)

302

Data In B1

100

Points to Jog Speed (100)

303

Data In B2

155

Points to Stop Mode A (155)

304

Data In C1

101

Points to Preset Speed 1 (101)

305

Data In C2

102

Points to Preset Speed 2 (102)

306

Data In D1

103

Points to Preset Speed 3 (103)

307

Data In D2

104

Points to Preset Speed 4 (104)

310

Data Out A1

140

Points to Accel Time 1 (140)

311

Data Out A2

142

Points to Decel Time 1 (142)

312

Data Out B1

100

Points to Jog Speed (100)

313

Data Out B2

155

Points to Stop Mode A (155)

314

Data Out C1

101

Points to Preset Speed 1 (101)

315

Data Out C2

102

Points to Preset Speed 2 (102)

316

Data Out D1

103

Points to Preset Speed 3 (103)

317

Data Out D2

104

Points to Preset Speed 4 (104)

RECOMM-PBUS

11

DPI I/O Config

xxx1 1111

Enables Cmd/Ref, Datalinks A-D

Figure 6.3 – Advanced I/O Configuration