Noise example 1, Noise example 1 -2 – Rockwell Automation System Design for the Control of Electrical Noise User Manual

Page 20

Publication GMC-RM001A-EN-P — July 2001

2-2

High Frequency (HF) Bonding

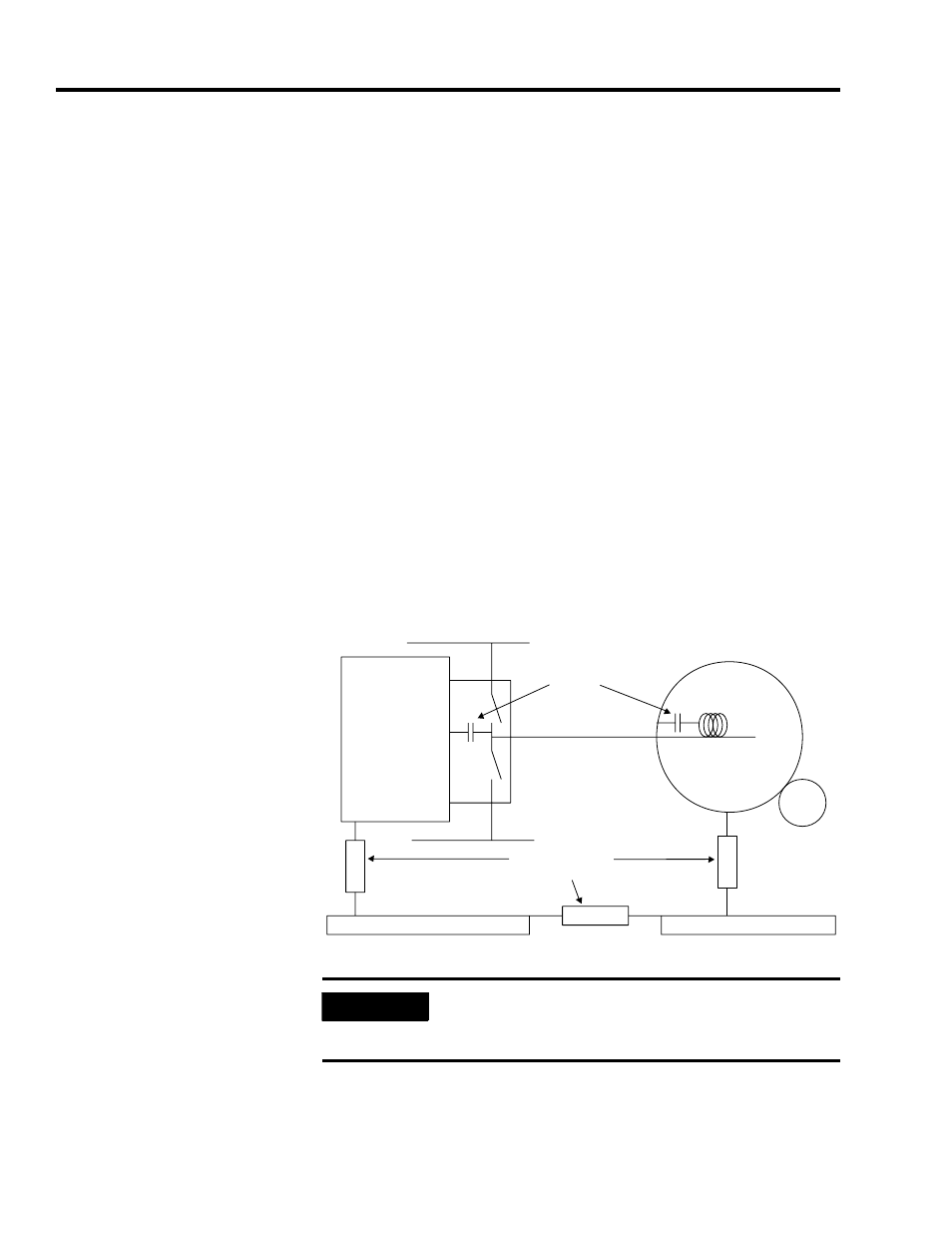

Noise Example 1

The transistors impose a 600V step change in the wire B (typically less

than 200nS). Stray capacitance A charges very rapidly causing a

current spike. This is the dominant noise source in PWM (Pulse Width

Modulated) drive systems.

The current circulates through stray capacitance C, bonding

impedance D, bonding impedance E, bonding impedance F, and back

to stray capacitance A. A voltage spike will appear between motor

frame and machine structure (Vd), between machine structure and the

panel (Ve) and between the panel and drive chassis (Vf).

The circuit of an encoder mounted on the motor will then have a

voltage spike of amplitude Vd + Ve relative to the panel and to any

input circuit on the panel, potentially a noise victim.

The noise voltages are proportional to the impedance of the bonds

(voltage = current x impedance). If these are reduced to zero, no

voltage will appear between encoder and panel.

Figure 2.1

Switching noise affecting encoder signal

+600V dc

DC common

Heatsink

(connected

to chassis)

Panel

Machine Structure

Windings

Motor

Drive

Stray

capacitance

Impedance due to

poor bonding

Transistor block

A

D

E

B

C

F

Encoder

IMPORTANT

The quality of bonding techniques applied during

installation directly affects the noise voltages

between system components.