Using a dynamic braking contactor, Attention – Rockwell Automation System Design for the Control of Electrical Noise User Manual

Page 115

Publication GMC-RM001A-EN-P — July 2001

Noise Control Supplement

A-13

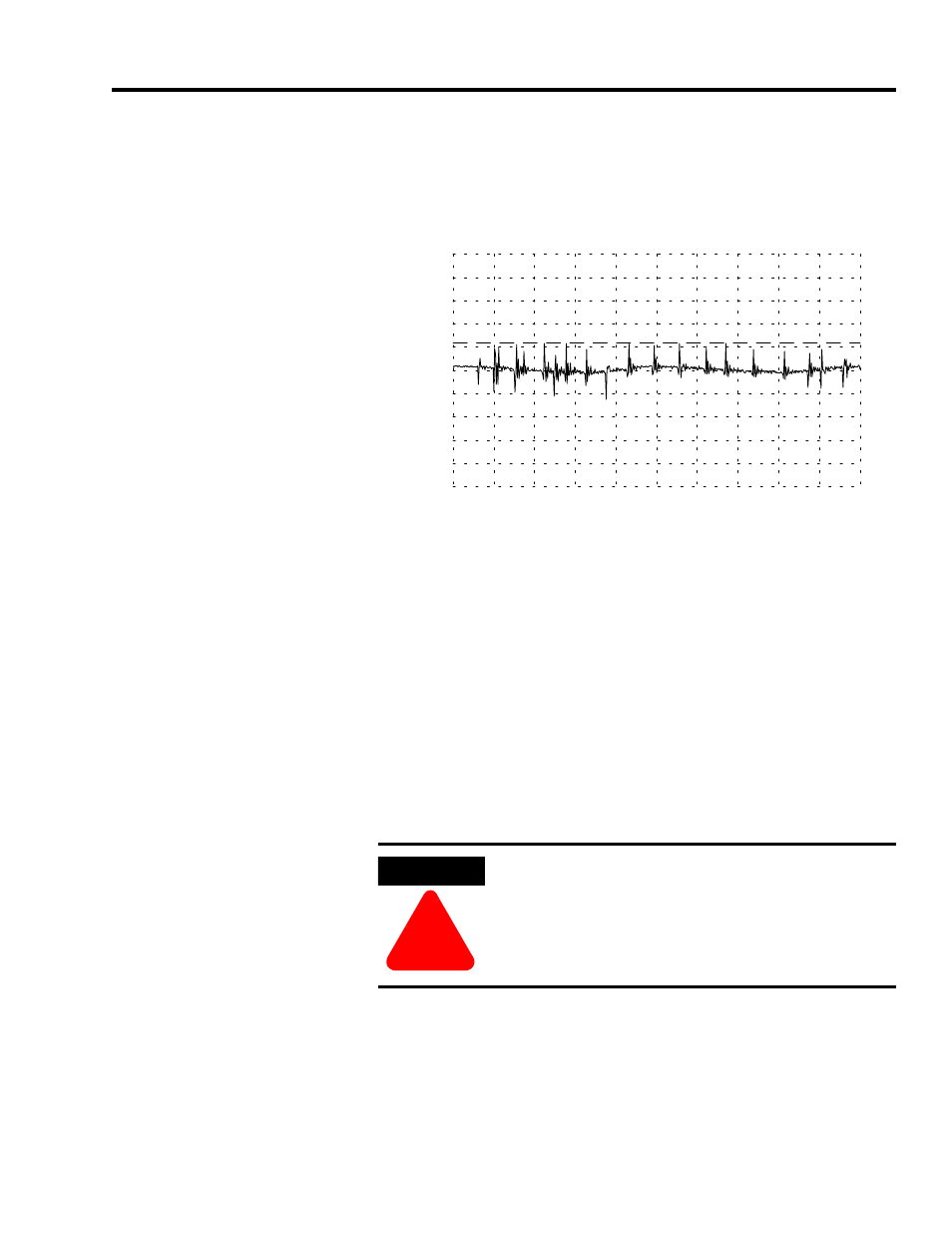

In Figure A.12 noise spikes greater than 2V, from an unsuppressed

inductive load are seen on the DC circuit of the second PSU.

Figure A.12

Noise spikes on +24V dc terminal of second PSU

Using a Dynamic Braking

Contactor

Dynamic braking (as shown in Figure A.13) requires the insertion of a

three-phase contactor between drive and motor and satisfies two

requirements.

•

Safety isolation where an operator must physically intervene in a

process. Usually combined with safety sensors such as a light

curtain.

•

Emergency braking in the event of power failure. This requires

three resistors connected across the motor windings by normally

closed contacts. The motor acts as a generator and the power is

dissipated by the resistors.

Note: Dynamic braking resistors are frequently confused with

dump-resistors which dissipate excess power from the DC bus

of a drive when a motor is regenerating.

µs

-10V

-8

-6

-4

-2

0

2

4

6

8

10V

2.3V pk

Victim Omron +24Vdc

DC floating

-1

0

1

2

3

4

5

6

7

8

9

ATTENTION

!

To avoid personal injury and/or damage to

equipment, the resistors must be installed. Opening

the circuit without resistors can result in very high

voltages due to motor inductance, prolonged arcing,

and eventually cause a fire in the contactor.