Reducing dynamic braking circuit noise – Rockwell Automation System Design for the Control of Electrical Noise User Manual

Page 116

Publication GMC-RM001A-EN-P — July 2001

A-14

Noise Control Supplement

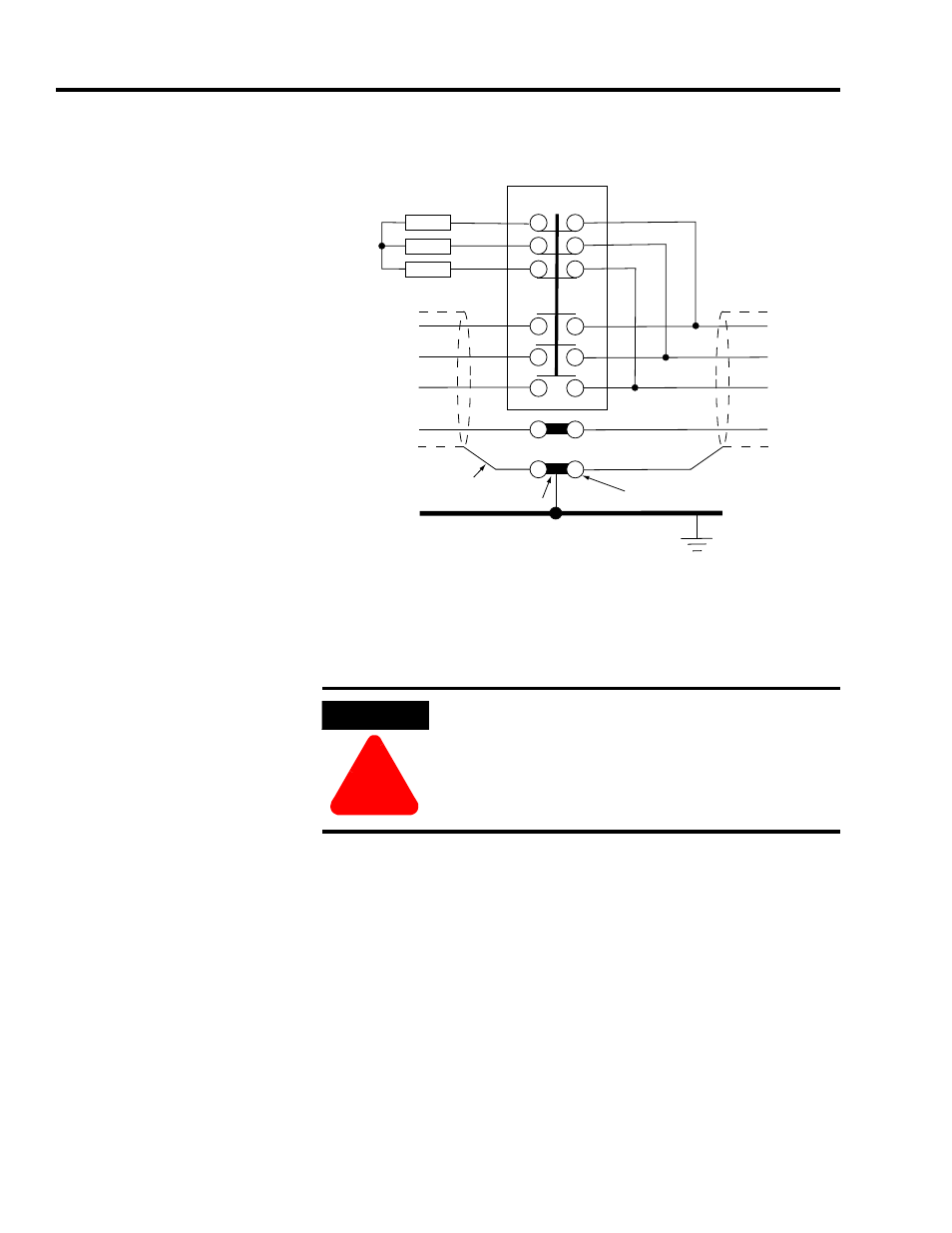

Figure A.13

Typical dynamic brake contactor interconnections

Note: Exposed power wiring conductors that are not shielded are a source of RFI noise. Keep exposed conductors as

short as possible and isolated from sensitive devices and wiring.

Note: The safety ground (GND) and shield connections are permanently connected. This is essential for electrical

safety.

Note: Unbraid all cable shields and bond together, connecting directly to the grounded terminal or stud. Do not use

the shield drain wire for this bonded connection.

Reducing Dynamic Braking Circuit Noise

Because the contactor and resistors are connected to the motor power

leads they carry the most intense noise levels in the system and

require special treatment to avoid noise related problems. Refer to the

guidelines below to reduce dynamic braking noise.

•

Mount unshielded components and wiring in the very-dirty zone.

•

Use shielded cable as much as possible. In some low-risk

applications it may be acceptable to twist the wires together

instead of shielding.

U

V

W

U

V

W

1

1

1

2

3

1

1

1

Resistor

Resistor

Resistor

Contactors

Unbraided shield

Grounded terminal or stud

Isolated terminal

Enclosure wall

Motor

Drive

ATTENTION

!

Implementation of safety circuits and risk assessment

is the responsibility of the machine builder. Please

reference international standards EN1050 and EN954

estimation and safety performance categories. For

more information refer to Understanding the

Machinery Directive (publication SHB-900).