Noise checklist – Rockwell Automation System Design for the Control of Electrical Noise User Manual

Page 118

Publication GMC-RM001A-EN-P — July 2001

A-16

Noise Control Supplement

Noise Checklist

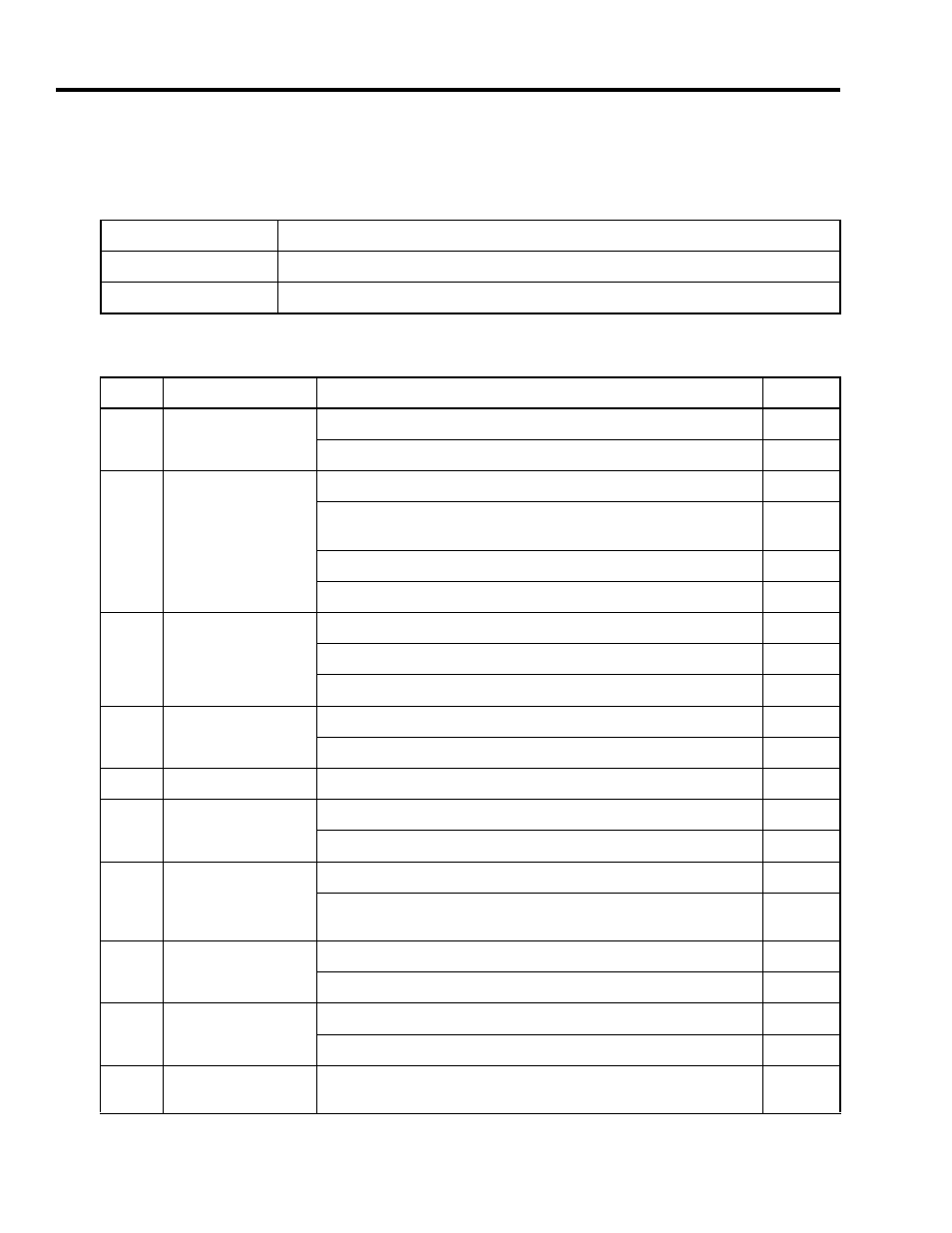

Use the following checklist to ensure that the number of potential

noise sources in your system is reduced and that the noise sensitive

components are not affected by the remaining noise.

System Identification:

Checked by:

Date:

Chapter

Title

Technique

Done

2

Zinc plated panels, bonded together top, middle, bottom

Panels bonded to machine structure by continuous low impedance paths

3

Segregating Sources and

Victims

Components segregated into Clean, Dirty and Very Dirty zones

Wiring segregated using color coded wireways with added shields, if

required

Wiring loops avoided

Wire run around the clean zone wireway to monitor for noise

4

Shielding Wires, Cables,

and Components

Additional shields between closely spaced zones

All clean signal cables shielded where appropriate

Shields grounded both ends at their circular cross section

5

EMC filters fitted adjacent to PWM loads

DC filters fitted where low voltage DC power crosses between zones

6

All contact-switched loads suppressed

7

Grounded DC power commons

De-coupled DC power at clean loads

8

Shielded cable for all VS motor power, grounded at both ends

Cable joints minimized (direct drive/motor preferred). Bulkhead connectors or

shielded junction boxes used.

9

High Speed Registration

Inputs

Shielded cable grounded to detector body and main panel

Clean power supply

10

Shielded cable grounded to detector body and main panel

Clean power supply

11

Measuring Noise

Reduction Effectiveness

Measure initial noise levels on DC distribution lines and install monitor wires

for periodic checks and recording