Rockwell Automation RECOMM-IBUS Interbus Communications Module User Manual

Page 40

5-10

Interbus Communications Module

The mapping in the scanner is set up in bytes. Inputs to the scanner

start at byte #512 and outputs start at byte #0.

PIDD/PODD parameter settings in the module determine the length

of I/O data mapped. In the example, each device is configured for 9

words (144 bits) of inputs and 9 words (144 bits) of outputs, the

maximum allowed for each device.

Using the PIDD/PODD values previously set in the RECOMM-IBUS

module, the I/O layout in the scanner is as shown in table 5.2.

Device 1.0’s SLC addressing is as follows:

Device 2.0’s SLC addressing starts immediately after 1.0

addressing (I:1.9 and O:1.9).

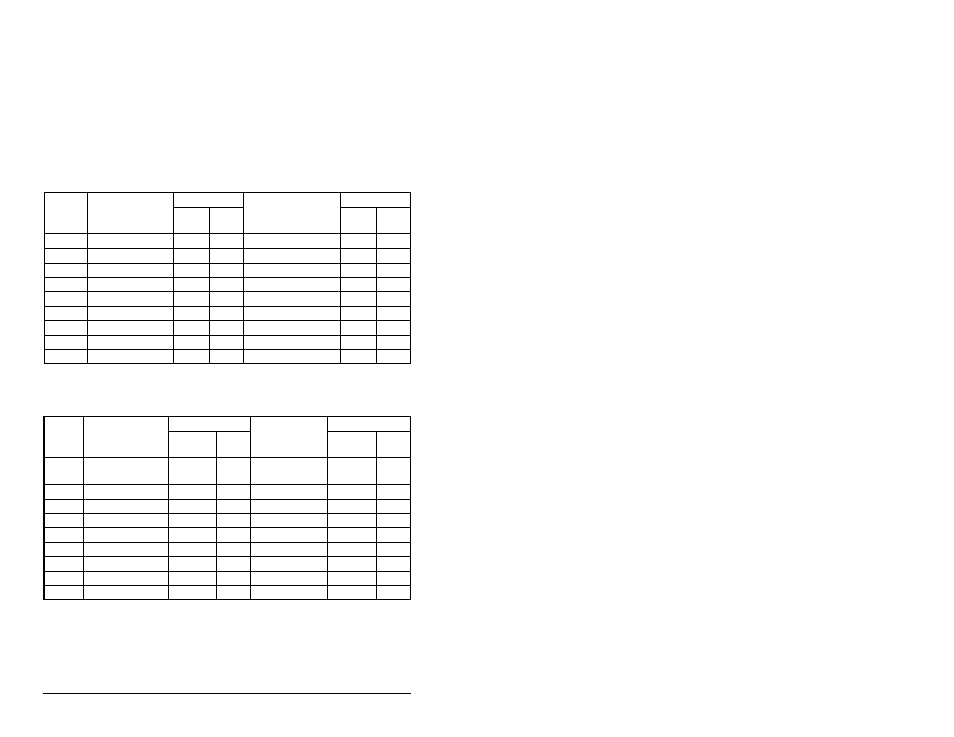

Table 5.2 – Scanner I/O Layout

Word

Inputs

(Data to Master)

Station

Outputs

(Data from

Master)

Station

1.0

2.0

1.0

2.0

0

Logic Status

512

530

Logic Command

0

18

1

Feedback

514

532

Reference

2

20

2

Datalink A1 Out

516

534

Datalink A1 In

4

22

3

Datalink A2 Out

518

536

Datalink A2 In

6

24

4

Datalink B1 Out

520

538

Datalink B1 In

8

26

5

Datalink B2 Out

522

540

Datalink B2 In

10

28

6

Datalink C1 Out

524

542

Datalink C1 In

12

30

7

Datalink C2 Out

526

544

Datalink C2 In

14

32

8

Datalink D1 Out

528

546

Datalink D1 In

16

34

Table 5.3 – SLC Addressing for Device 1.0

Word

Inputs

(Data to

Master)

Assignment

Outputs

(Data from

Master)

Assignment

Scanner SLC

Scanner SLC

0

Logic Status

512

I:1.0 Logic

Command

0

O:1.0

1

Feedback

514

I:1.1 Reference

2

O:1.1

2

Datalink A1 Out

516

I:1.2 Datalink A1 In

4

O:1.2

3

Datalink A2 Out

518

I:1.3 Datalink A2 In

6

O:1.3

4

Datalink B1 Out

520

I:1.4 Datalink B1 In

8

O:1.4

5

Datalink B2 Out

522

I:1.5 Datalink B2 In

10

O:1.5

6

Datalink C1 Out

524

I:1.6 Datalink C1 In

12

O:1.6

7

Datalink C2 Out

526

I:1.7 Datalink C2 In

14

O:1.7

8

Datalink D1 Out

528

I:1.8 Datalink D1 In

16

O:1.8