3 configuring the network using cmd software – Rockwell Automation RECOMM-IBUS Interbus Communications Module User Manual

Page 33

Configuring the Interbus Scanner

5-3

PIDD and PODD parameters are used to identify what will be

transmitted on the network and the amount of network I/O the CMD

software will allocate on the scanner.

5.3

Configuring the Network Using CMD

Software

Before starting the network configuration process, make sure the

PC running CMD software is connected to the SST scanner (a null

modem cable is supplied with the scanner). The SLC and drives

need to be connected to the Interbus network and powered in order

for CMD software to configure the network. The CMD software tool

automatically creates a Reliance Electric sub-folder (in the Slaves

folder), if it does not already exist.

CMD needs to be in Extended Mode to configure the network. A

password (supplied by Phoenix Contact along with the CMD

software), is requested for this functionality each time CMD is

started. After CMD has started, you can also click Options/

Extended (Function Scope) to enter the password.

Step 1.

Select File / New from the pull-down menu to create a

new project. (See figure 5.2.)

28

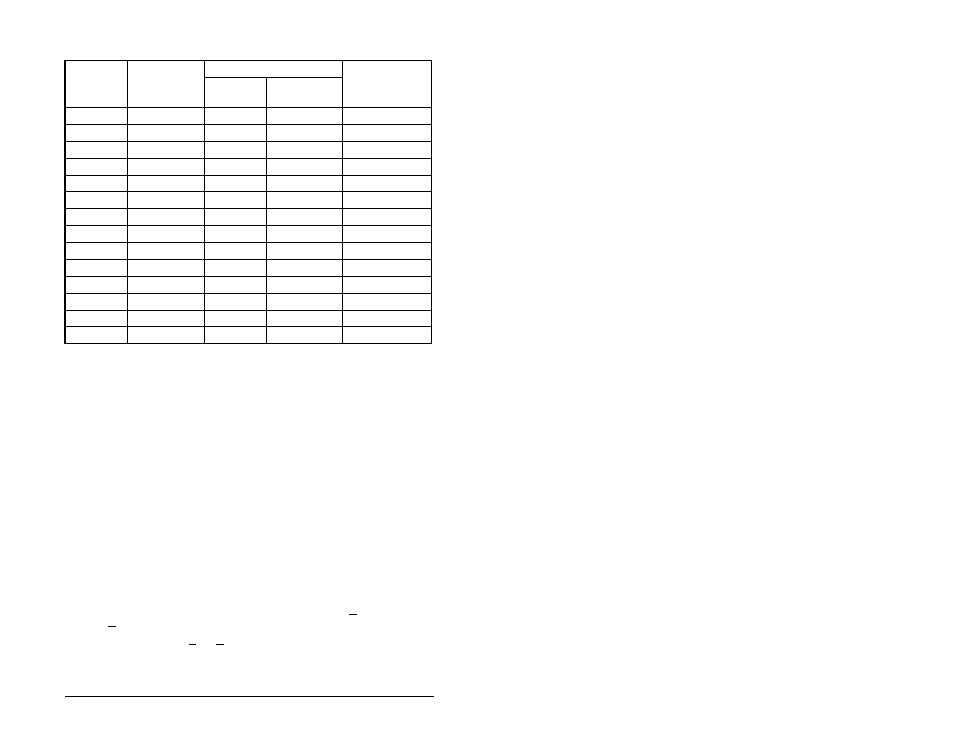

PIDD W4 Cfg

12198

2FA6

Datalink B1 Out

30

PIDD W5 Cfg

12199

2FA7

Datalink B2 Out

32

PIDD W6 Cfg

12200

2FA8

Datalink C1 Out

34

PIDD W7 Cfg

12201

2FA9

Datalink C2 Out

36

PIDD W8 Cfg

12202

2FAA

Datalink D1 Out

38

PODD W0 Cfg

12184

2F98

Logic Command

40

PODD W1 Cfg

12185

2F99

Reference

42

PODD W2 Cfg

12188

2F9C

Datalink A1 In

44

PODD W3 Cfg

12189

2F9D

Datalink A2 In

46

PODD W4 Cfg

12190

2F9E

Datalink B1 In

48

PODD W5 Cfg

12191

2F9F

Datalink B2 In

50

PODD W6 Cfg

12192

2FA0

Datalink C1 In

52

PODD W7 Cfg

12193

2FA1

Datalink C2 In

54

PODD W8 Cfg

12194

2FA2

Datalink D1 In

Table 5.1 – Module Parameter Settings for Ladder Example (Continued)

Parameter

Name

Value

Description

Binary/

Decimal

Hexadecimal