2 using the lcd oim to configure the module, 3 setting the i/o configuration – Rockwell Automation RECOMM-IBUS Interbus Communications Module User Manual

Page 22

4-2

Interbus Communications Module

4.2

Using the LCD OIM to Configure the

Module

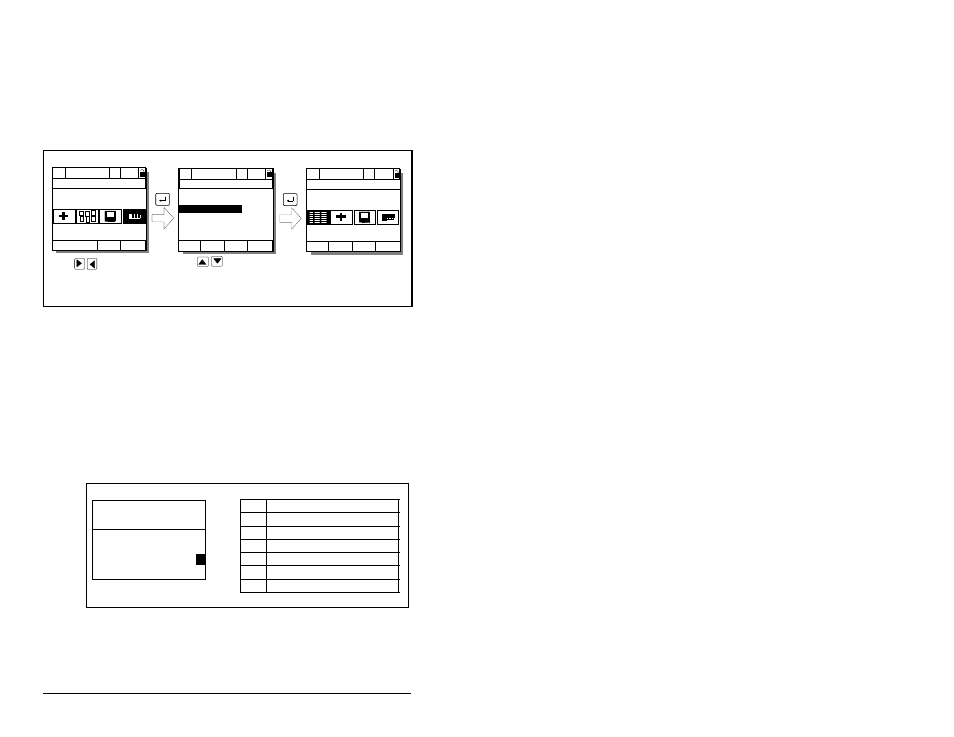

Use the procedure in figure 4.1 to access the parameters on the

Interbus module using the LCD OIM. If you are unfamiliar with the

operation of the LCD OIM, refer to the SP600 AC Drive User Manual

(D2-3485) for more information.

4.3

Setting the I/O Configuration

The I/O configuration determines the data that is sent to and from

the drive. This is a two part process: enabling/disabling the data

transmitted between the module and drive, and identifying the data

transmitted between the module and the scanner.

Step 1.

Enable or disable the data transmitted between the

module and drive by setting the bits in DPI I/O Config (8).

A “1” enables the I/O. A “0” disables the I/O.

Bit 0 is the right-most bit. In figure 4.2, it is highlighted and equals

“1.”

Figure 4.1 – Accessing the Interbus Parameters using the LCD OIM

P0: SP600

> >

Auto

Stopped

Main Menu

Device Select

Use to select

R E C O M M - I B U S .

P0: SP600

> >

Auto

Stopped

P5: RECOMM-IBUS

> >

Auto

Stopped

Main Menu

Parameters

Device: Port 0

SP600

R E C O M M - I B U S

Monitor

Lang

Edit the Interbus

parameters using the

same techniques as for

drive parameters.

Use to highlight

Device Select icon

Figure 4.2 – I/O Configuration Screen on an LCD OIM

Bit

Description

0

Logic Command/Reference (Default)

1

Datalink A

2

Datalink B

3

Datalink C

4

Datalink D

5 - 16 Not Used

Port 5 Device

RECOMM-IBUS

Parameter #: 8

DPI I/O Config

x x x x x x x x x x x 0 0 0 0

1

Cmd/Ref

b00

LCD OIM Screen