Rockwell Automation RECOMM-IBUS Interbus Communications Module User Manual

Page 24

4-4

Interbus Communications Module

To configure the module for Logic Command/Status,

Reference/Feedback and the maximum number of

Datalinks enabled in see the example in table 4.3.

Note that Datalink D2 is not used in this example because

maximum configuration has been reached. The maximum

configuration is shown to illustrate utilizing all 9 words of

inputs and 9 words of outputs. Depending on your

application needs, any subset of the above example can

be implemented.

The corresponding DPI I/O Config (8) setting would be

“11111” for all of the above information to transfer

between the module and the drive.

Step 5.

Reset the module. Refer to the section 4.4.3, Resetting

the Module, in this chapter.

The module is ready to receive I/O from the master (i.e., scanner).

You must now configure the scanner to recognize and transmit I/O

to the module. Refer to chapter 5, Configuring the Interbus Scanner.

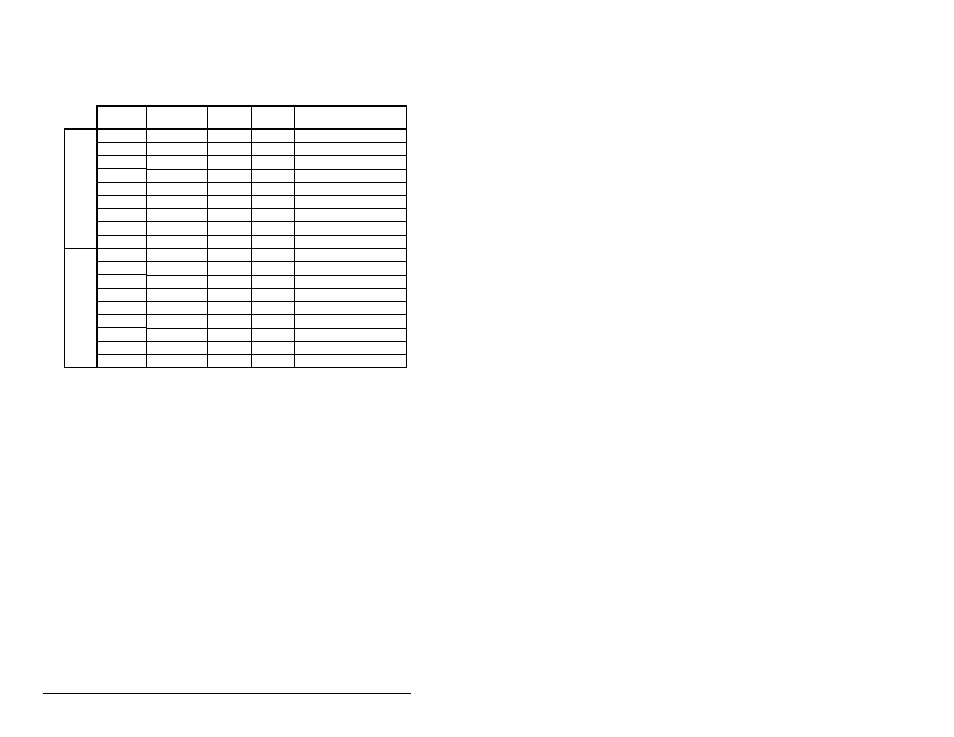

Table 4.3 – Module I/O Configuration Example

Parameter #

Name

Value

(Hex)

Value

(Dec)

Description

20

PIDD W0 Cfg

2F9A

12186

Logic Status (default)

22

PIDD W1 Cfg

2F9B

12187

Feedback (default)

24

PIDD W2 Cfg

2FA4

12196

Datalink A1 Out

26

PIDD W3 Cfg

2FA5

12197

Datalink A2 Out

Input

28

PIDD W4 Cfg

2FA6

12198

Datalink B1 Out

30

PIDD W5 Cfg

2FA7

12199

Datalink B2 Out

32

PIDD W6 Cfg

2FA8

12200

Datalink C1 Out

34

PIDD W7 Cfg

2FA9

12201

Datalink C2 Out

36

PIDD W8 Cfg

2FAA

12202

Datalink D1 Out

38

PODD W0 Cfg

2F98

12184

Logic Command (default)

40

PODD W1 Cfg

2F99

12185

Reference (default)

42

PODD W2 Cfg

2F9C

12188

Datalink A1 In

44

PODD W3 Cfg

2F9D

12189

Datalink A2 In

Output

46

PODD W4 Cfg

2F9E

12190

Datalink B1 In

48

PODD W5 Cfg

2F9F

12191

Datalink B2 In

50

PODD W6 Cfg

2FA0

12192

Datalink C1 In

52

PODD W7 Cfg

2FA1

12193

Datalink C2 In

54

PODD W8 Cfg

2FA2

12194

Datalink D1 In