Wire size and terminal screw torque, I/o memory mapping, Output data file – Rockwell Automation 1769-OF8V CompactLogix Analog Output Module User Manual

Page 17

CompactLogix Analog Output Module 17

Rockwell Automation Publication 1769-IN089A-EN-P - March 2011

3.

Tighten the terminal screw making sure the pressure plate secures the

wire. Recommended torque when tightening terminal screws is 0.68

N•m (6 in•lb).

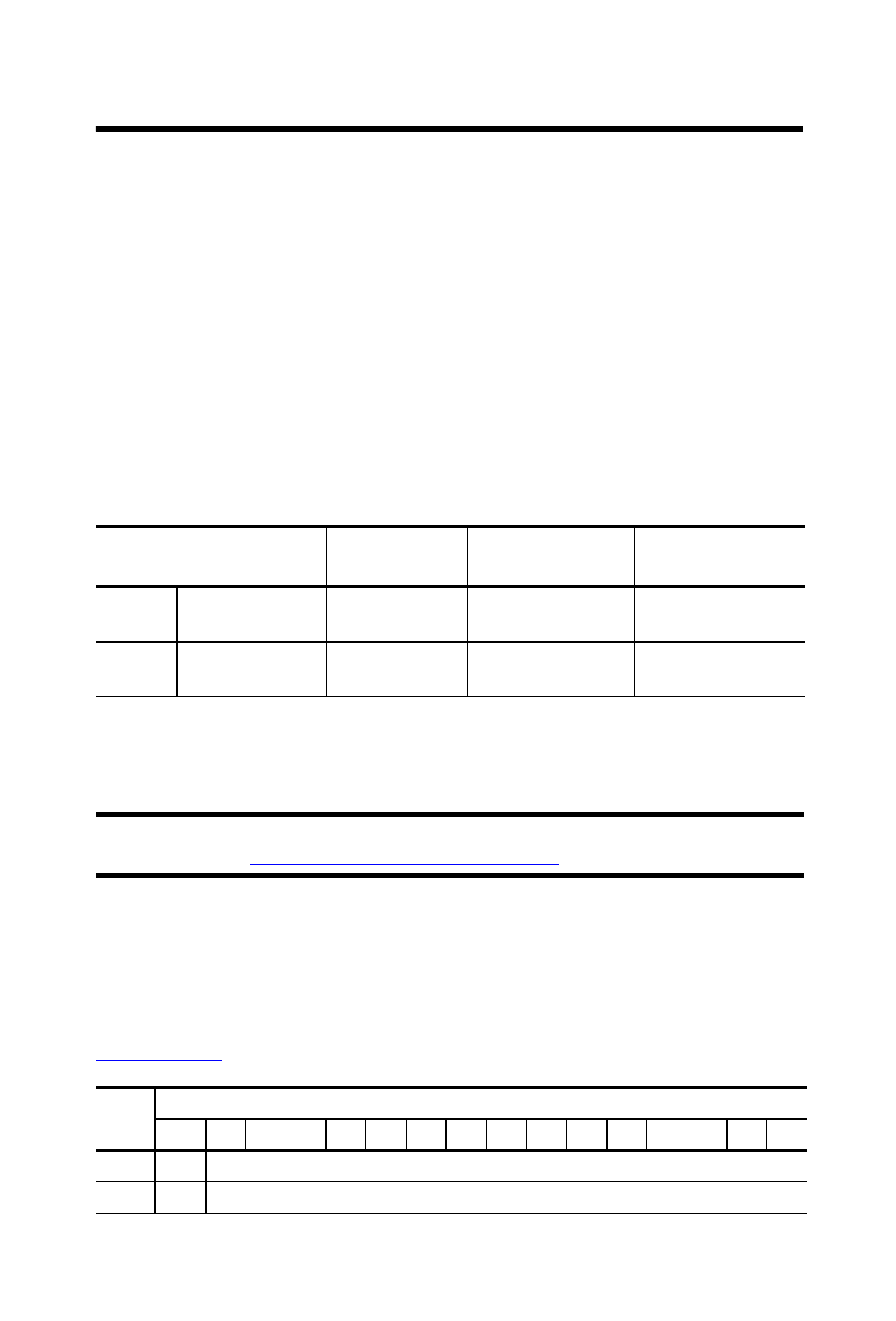

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions.

I/O Memory Mapping

Output Data File

For each module, slot x, words 0…7 in the output data file contain the channel

0 …7 output data. Word 8 is used to unlatch any condition that has been latched.

Refer to the Compact I/O Analog Modules User Manual, publication

or additional details.

TIP

If you need to remove the finger-safe cover, insert a screw driver into one

of the square, wiring holes and gently pry the cover off. If you wire the

terminal block with the finger-safe cover removed, you will not be able to

put the cover back on the terminal block because the wires will obstruct

the cover.

Wire Type

Wire Size

Terminal Screw

Torque

Retaining Screw

Torque

Solid

Cu-90 °C (194 °F) #14…#22 AWG

0.68 N•m

(6 lb•in)

0.46 N•m

(4.1 lb•in)

Stranded Cu-90 °C (194 °F) #16…#22 AWG

0.68 N•m

(6 lb•in)

0.46 N•m

(4.1 lb•in)

IMPORTANT

If you are using RSLogix 5000 software, version 15, please refer to

RSLogix 5000 Controller Tags on page 22

Wo

rd

Bit Position

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

0

SGN

Analog Output Data Channel 0

1

SGN

Analog Output Data Channel 1