Rockwell Automation 1746-FIO4V SLC 500 Fast Analog I/O/ User Manual User Manual

Page 60

Publication 1746-UM009B-EN-P - September 2007

60 Write Ladder Logic

Brake Monitor Example Program for SLC 5/02 (or later) Processors

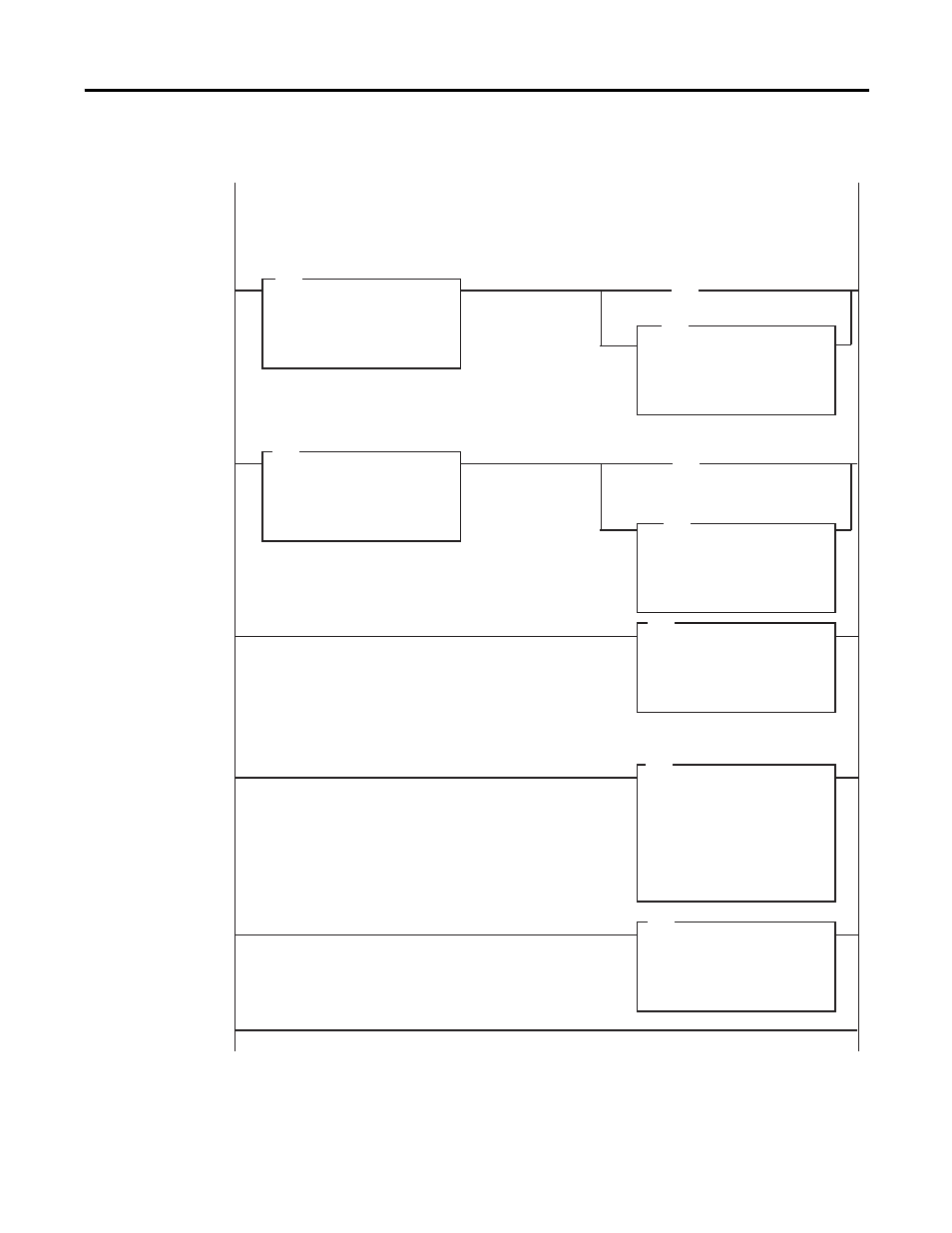

Rung 2:2

The next 2 rungs ensure that the analog input value to be scaled remains within the limits of 409 and 2047. This

prevents out-of-range conversion errors in the SCL and PID instructions. The latch bits can be used elsewhere in the

program to identify the particular out-of-range error which occurred.

Rung 2:3

Rung 2:4

Rung 2:6

This rung immediately updates the analog output card driven by the PID’s CV.

Rung 2:7

+END+

Rung 2:5

The PID control variable is the input for the scale instruction. The PID instruction guarantees that the CV remains

within the range of 16383. The CV is scaled to 6242–31208, the numeric range required for a 4–20 mA output signal.

Under

RangeB3

(L)

0

Over

Range

B3

1

GRT

GREATER THAN

Source A

Source B

N7:0

0

2047

LES

LESS THAN

Source A

Source B

N7:0

0

409

MOV

MOVE

Source A

Dest

409

N7:0

0

MOV

MOVE

Source

Dest

2047

N7:0

0

PID

PID

Control Block

Process Variable

Control Variable

Control Block Length

N10:0

N7:0

N10:29

SCL

SCALE

Source

Rate (1/10000)

Offset

Dest

N10:29

0

15239

6242

O:1.0

IOM

IMMEDIATE OUT w MASK

Slot

Mask

Length

O:1.0

FFFF

(L)