Auxiliary contacts inspection and replacement – Rockwell Automation 1512A MV Controllers - 800A One-High Cabinet User Manual

Page 62

5-14

Maintenance

1512A-UM102B-EN-P – June 2013

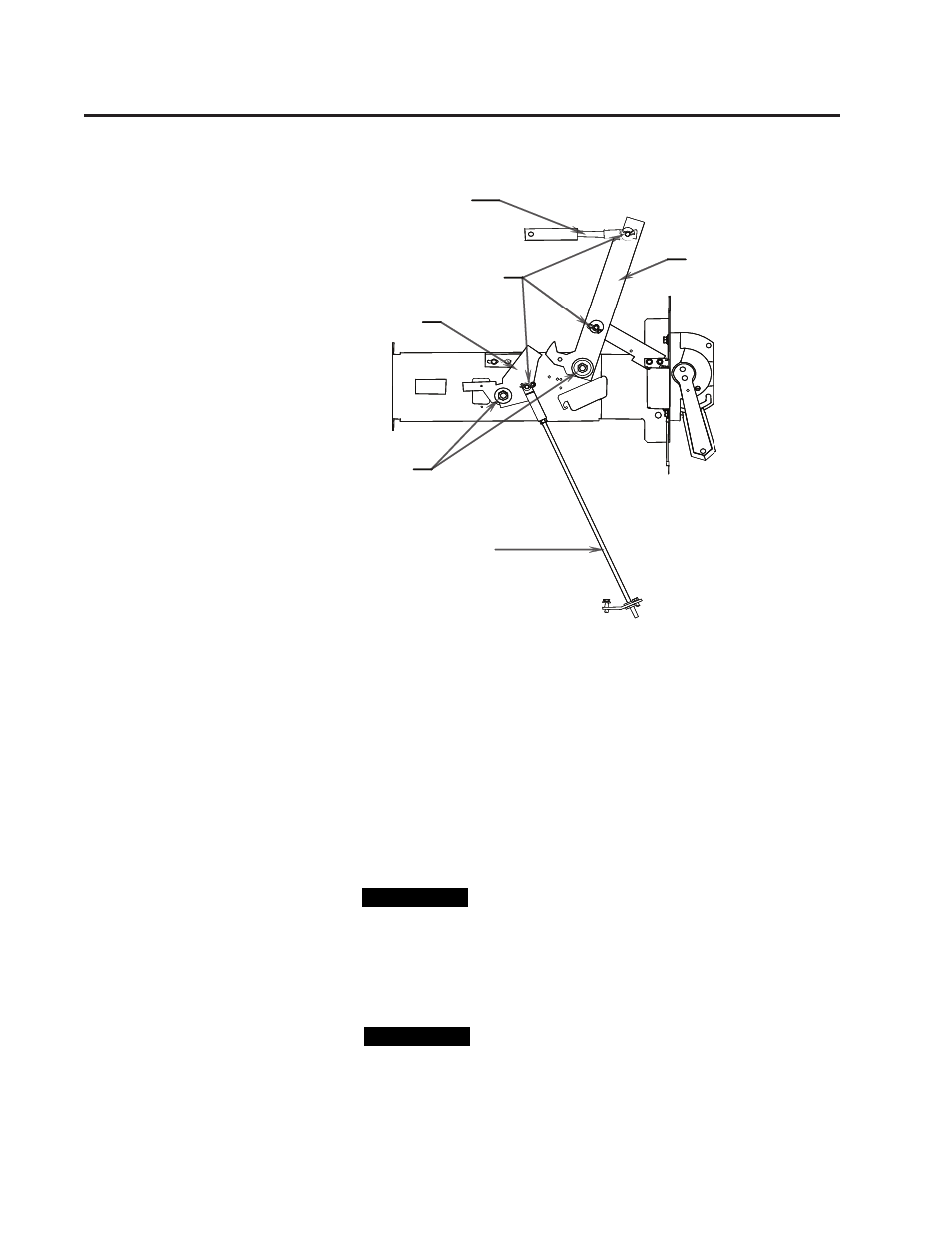

Threaded Connecting Rod

Clevis Pins and Cotter Pins

Switch Interlock Lever

Isolation Switch

Operating Lever

Lubrication Points

(Only at replacement)

Contactor Interlock Rod

Threaded Connecting Rod

Clevis Pins and Cotter Pins

Switch Interlock Lever

Isolation Switch

Operating Lever

Lubrication Points

(Only at replacement)

Contactor Interlock Rod

Figure 5.12 – Isolation Switch Handle Mechanism Lubrication Points

5) Inspect the mounting hardware on the isolation switch operating

lever and contactor interlock rod (see Figure 5.11). Tighten any

loose hardware.

6) Inspect the isolation switch blades and the incoming line stabs (see

Figure 5.12). The mating surfaces must be clean and well lubricated.

7) Remove any dirt and dried grease.

Do not scrape or file the parts. This may remove the

plating and expose the underlying copper to corro-

sion.

8) Lubricate the isolation switch blades and the isolation switch blade

pivot points with Nyogel 759G (see Figure 5.12).

Lubricate the isolation switch blades a minimum of

once per year to avoid excessive wear to the compo-

nents and to prevent the isolation switch blades from

overheating.

Auxiliary Contacts

Inspection and Replacement

I M P O R T A N T

I M P O R T A N T

I M P O R T A N T

I M P O R T A N T

Isolation Switch Mechanism

Inspection and Lubrication

(cont.)