Production, Process flow – USG Casting Fireplace Surrounds User Manual

Page 20

Drying

To achieve uniform results and optimal physical properties, all gypsum cement castings must be properly dried.

This is probably the most important step in the entire process of fabricating fireplace surrounds. Make sure parts

are completely supported after demolding so that the shape does not change. Proper drying will allow for:

– Maximum strength development

– Uniform absorption

– Increased production capabilities

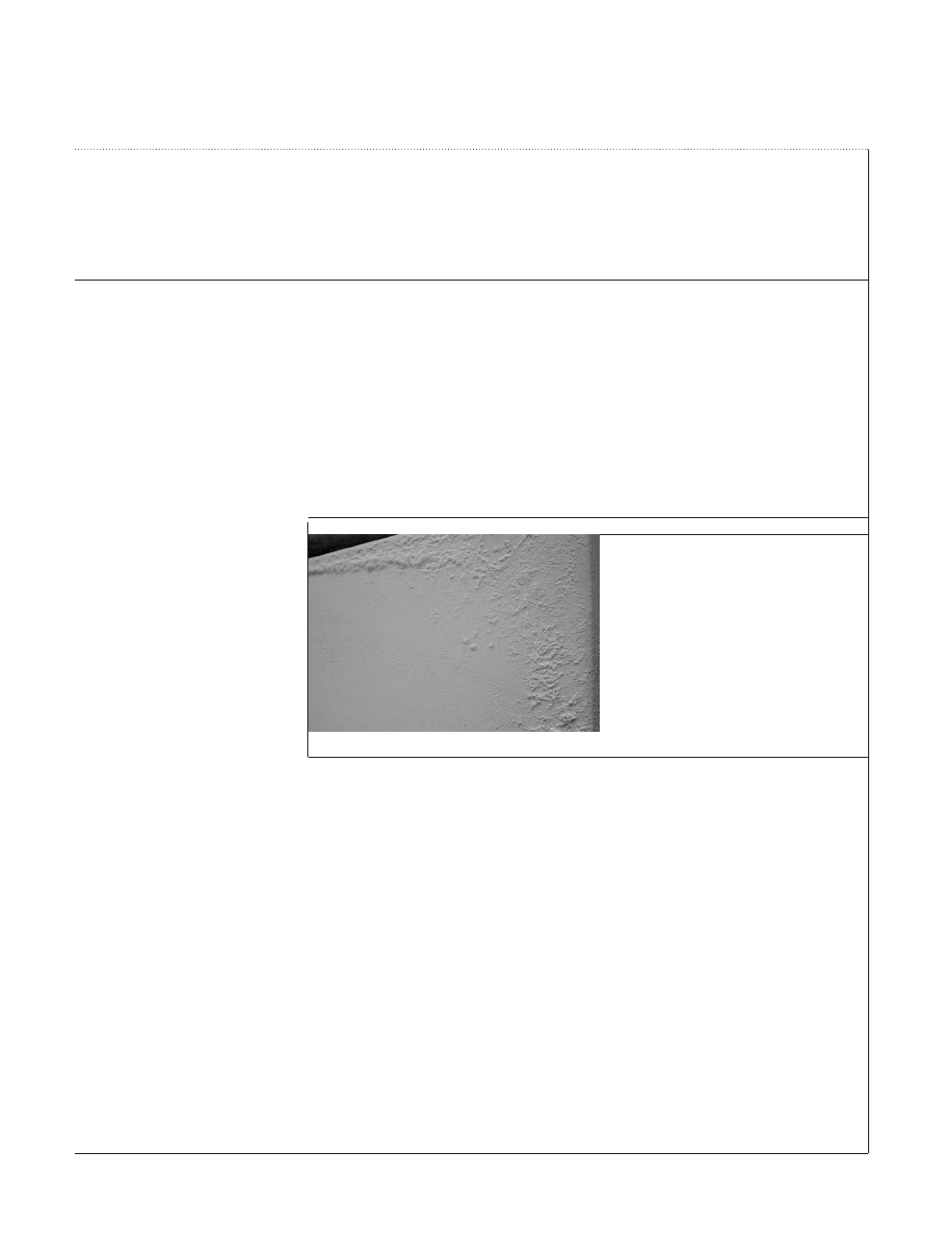

– Reduced efflorescence (soluble salts that migrate to the surface of the part and cause chalky spots on the

part – see photo below)

– Mold and mildew prevention

– Better paintability/finishing

Efflorescence on the Surface of a Mantel

Gypsum cements require approximately 19 lbs. of water per 100 lbs. of powder by weight for complete hydration

in the setting process. However, additional amounts of water are needed to obtain a mixable slurry. After the

material is mixed, cast, and has set, any water in excess of the 19 parts needed is considered excess or “free” water

and must be removed by drying. In addition, moisture left in the part may lead to the growth of mold or mildew.

Production

Process Flow

20

Casting Fireplace Surrounds