Production, Mold materials – USG Casting Fireplace Surrounds User Manual

Page 12

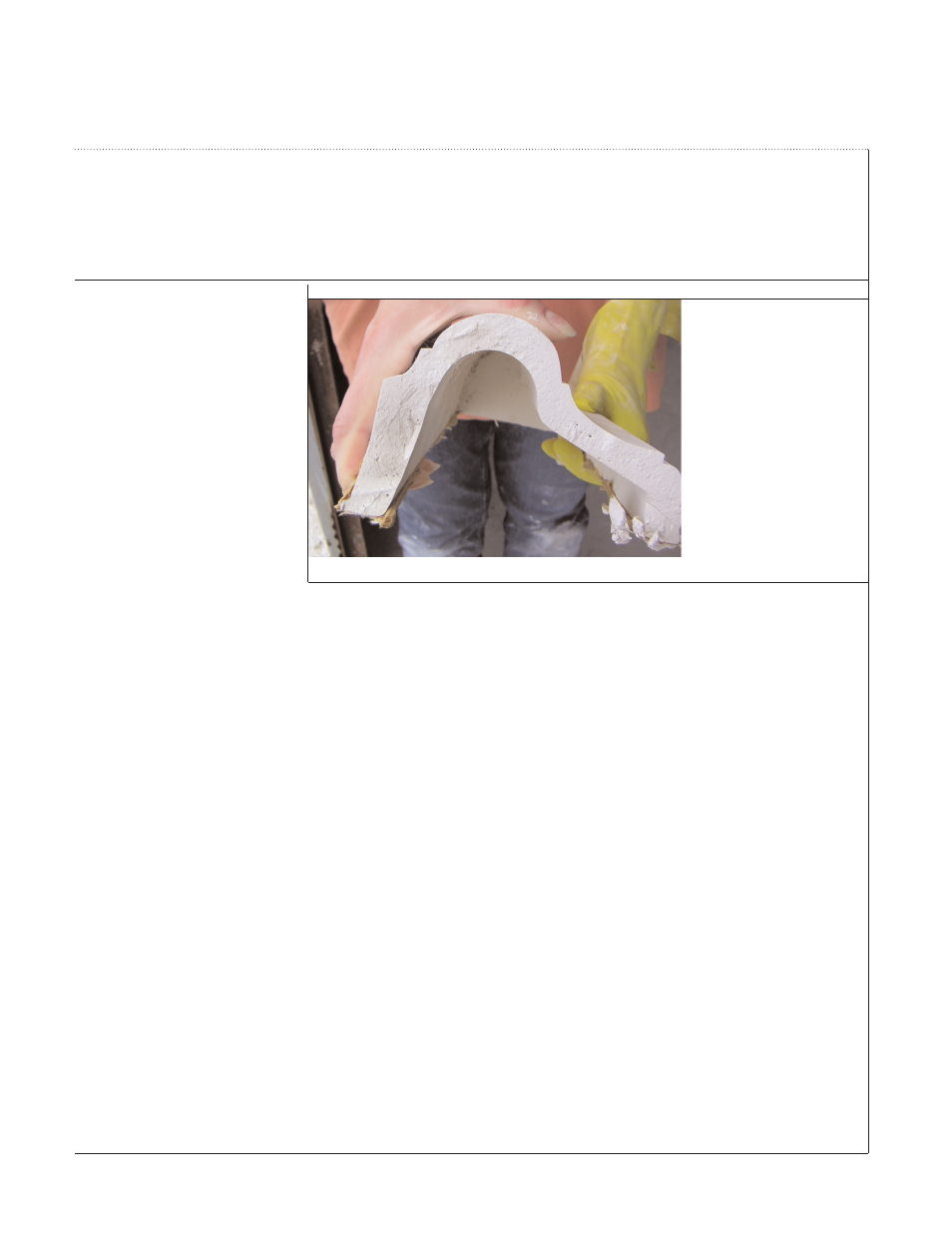

Cross-Sectional Depth of Mold Design

Gypsum cements can be fabricated in either rigid or flexible mold materials. The choice depends on the design

and texture of the fireplace surround. In general, the flatter and smoother the surface, the more likely it can be

done in a rigid mold. Another factor to consider when selecting molds is the ease of reassembly after removing

a finished part. Rigid molds generally will have more parts to reassemble compared to flexible molds.

Rigid molds may be made of wood, metal, or plastic, but since gypsum cement products are water activated,

some rigid mold materials may require sealing to prevent water penetration, while others will need sealers as well

as parting agents to prevent the fabricated piece from sticking to the mold surface.

When aluminum metal is used as a mold material, alkaline-formula gypsum products may attack it unless it

is protected with a coating. In some cases there may be an advantage in using molds that have a combination

of flexible and rigid properties.

Flexible molds are usually more expensive than rigid molds, but do not typically require the use of sealing or

parting products and can usually be made in fewer pieces than rigid molds. The best flexible material for

fireplace ornamentation is polyurethane rubber. Silicone rubber will also perform well, but is more expensive than

polyurethanes, so its use should be limited to special situations. If silicone molds already exist due to production

of resin materials, they can be used for casting gypsum cements. Other flexible mold materials like latex are

available, but the curing shrinkage of this rubber makes it very difficult to use for large pieces. Regardless of the

flexible mold material you select, you will need a matching rigid support to hold the mold firmly when the casting

procedure takes place.

Molds can be designed and fabricated to allow for specific textures on the finished parts, such as an antique or

travertine look, or an uneven surface resembling natural limestone or granite. It is important to consider your

target market when designing and fabricating molds.

Production

Mold Materials

12

Casting Fireplace Surrounds