Production, Fiber reinforcement – USG Casting Fireplace Surrounds User Manual

Page 14

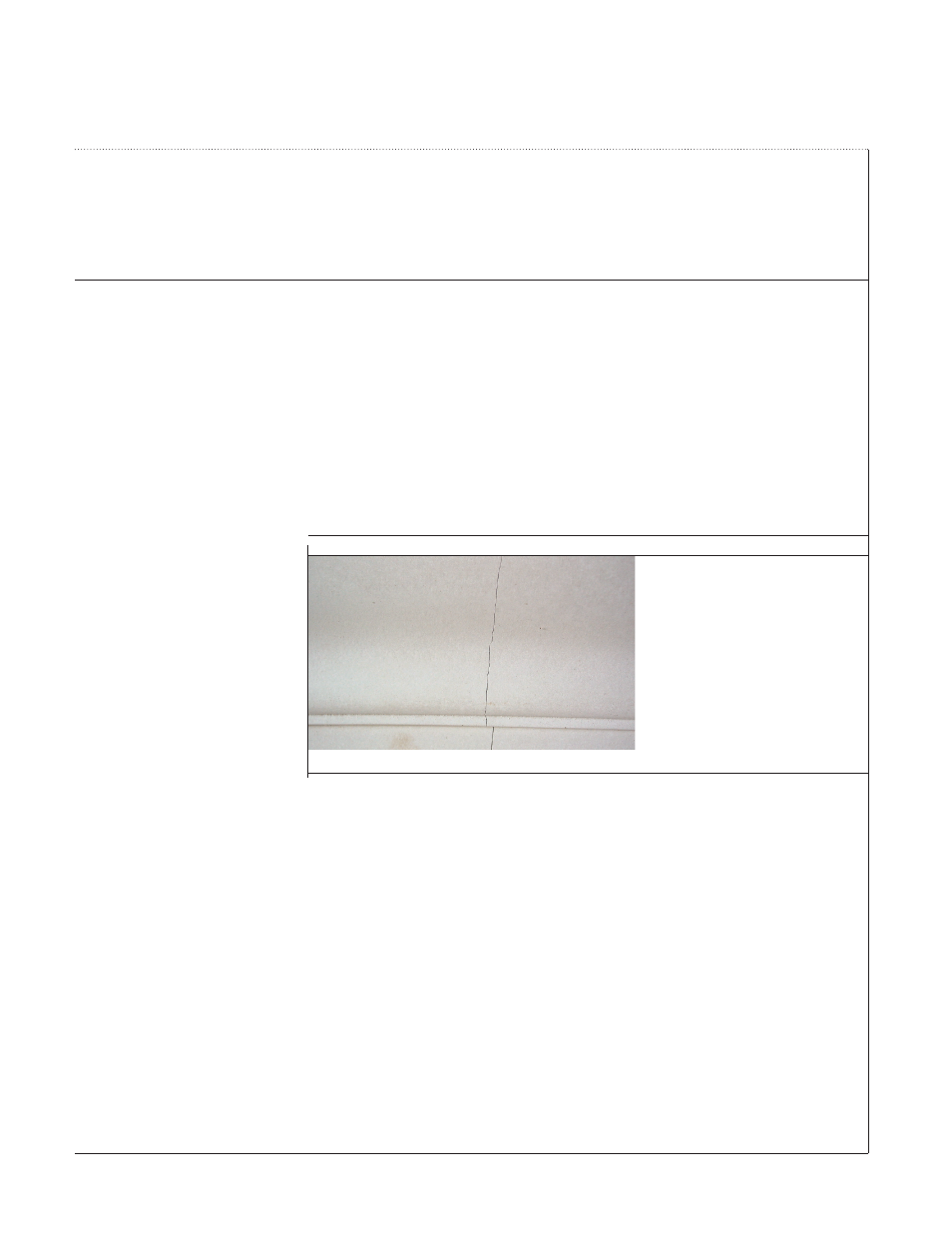

Fiber reinforcement should always be used when manufacturing

fireplace surrounds. Glass fiber matting and/or chopped glass fiber

strands can be used for hand-layup and spray processes. The

recommended proportion of fibers is 5% - 6% of the weight of the

mix. (See Manufacturing.) This proportion provides increased

impact strength, flexural strength, and resistance to breakage during

shipping, handling, and installation. Using glass fiber will also

minimize the potential for cracking during normal use.

A Surround without Fiber Reinforcement Exhibits Cracking During Thermal Testing

There are several different types of glass fibers. Use fibers that are compatible with the gypsum cements you are

using, as some alkaline gypsum cement formulations can have a detrimental effect on fibers. To maximize the ben-

efits of fiber reinforcement, review fiber thickness and chopped lengths. The type of fabrication process you use will

also determine the type of fibers you need. Your USG sales representative can help with selection of the best fibers

for your specific products.

Production

Fiber Reinforcement

14

Casting Fireplace Surrounds