Required insulation thicknesses – Roxul Industrial Insulation Process User Manual

Page 30

Insulation of piping

Required insulation thicknesses

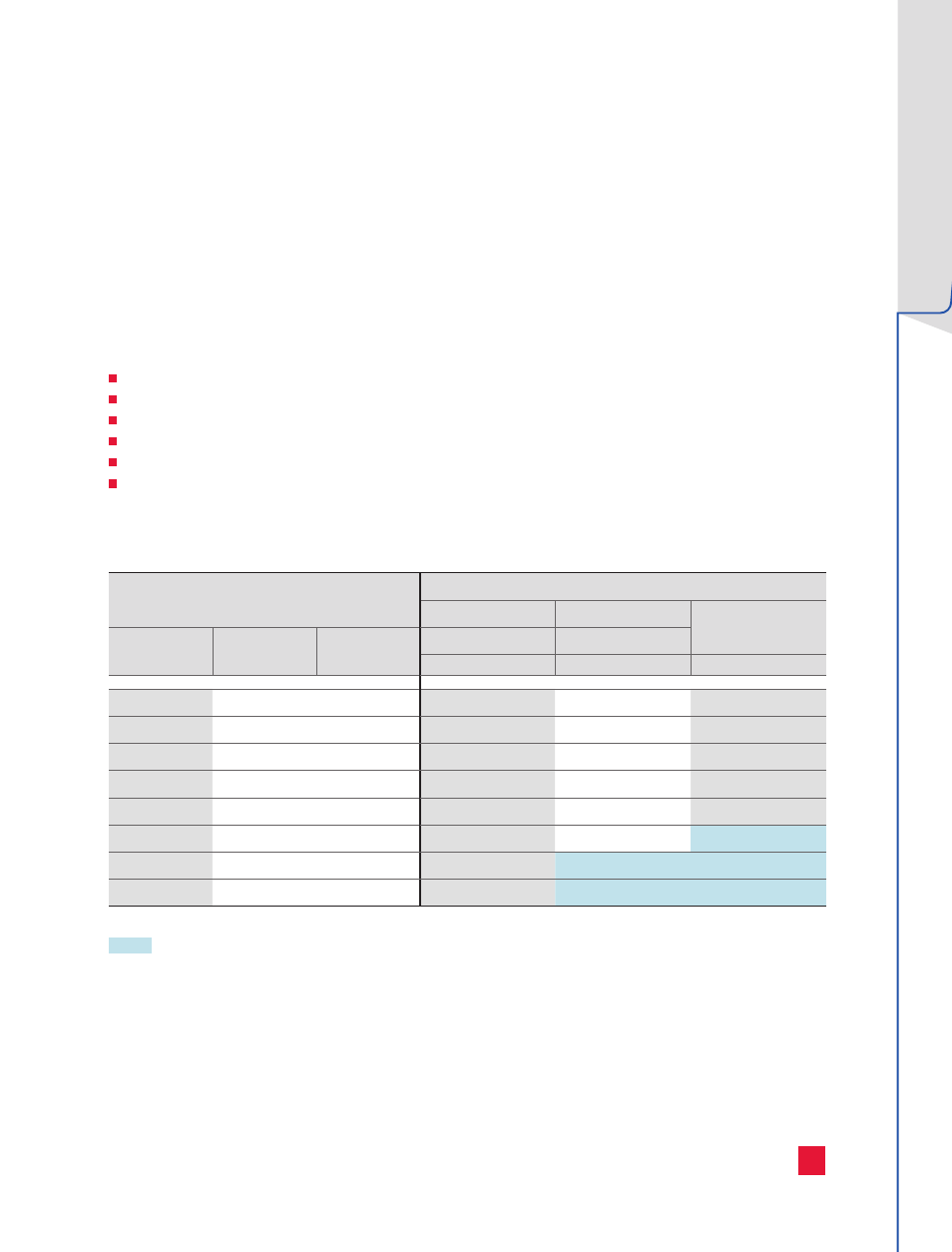

If the three insulation systems are compared,

taking into consideration similar heat losses,

clear advantages are seen with regard to the

insulation thicknesses with systems using pipe

sections or pipe wraps (mats). These do not use

spacers, in contrast to insulation systems made

using wired mats. The table below shows the

required insulation thicknesses taking into

account the following boundary conditions:

Medium temperature: 480 °F (250 °C)

Ambient temperature: 50 °F (10 °C)

Wind speed: 1.1 mph (5 m/s)

Cladding: Aluminum

Heat loss: 150 BTU/ft.hr (150 W/m)

Application of spacers in the case of wired mats

Pipe Diameter

Minimum Insulation Thickness

Pipe sections

Pipe wraps (mats)

Wired mats

NPS

(inch)

Nominal diameter

Ø DN

Pipe diameter

(mm)

ProRox

®

PS 960

NA

ENERWRAP

®

MA 960

NA

inch

inch

inch

2

50

60

1"

n.a.

n.a.

3

80

89

1"

n.a.

n.a.

4

100

108

1.5"

n.a.

n.a.

6

150

159

2"

n.a.

n.a.

8

200

219

2.5"

n.a.

5"

10

250

273

3"

n.a.

6"

12

300

324

4"

4"

7.5"

14

350

356

4.5"

4.5"

8"

Multiple layer insulation

n.a. = not applicable

27