1 planning and preparation, Planning and pr epar ation – Roxul Industrial Insulation Process User Manual

Page 24

Planning and pr

epar

ation

1.1 Planning and preparation

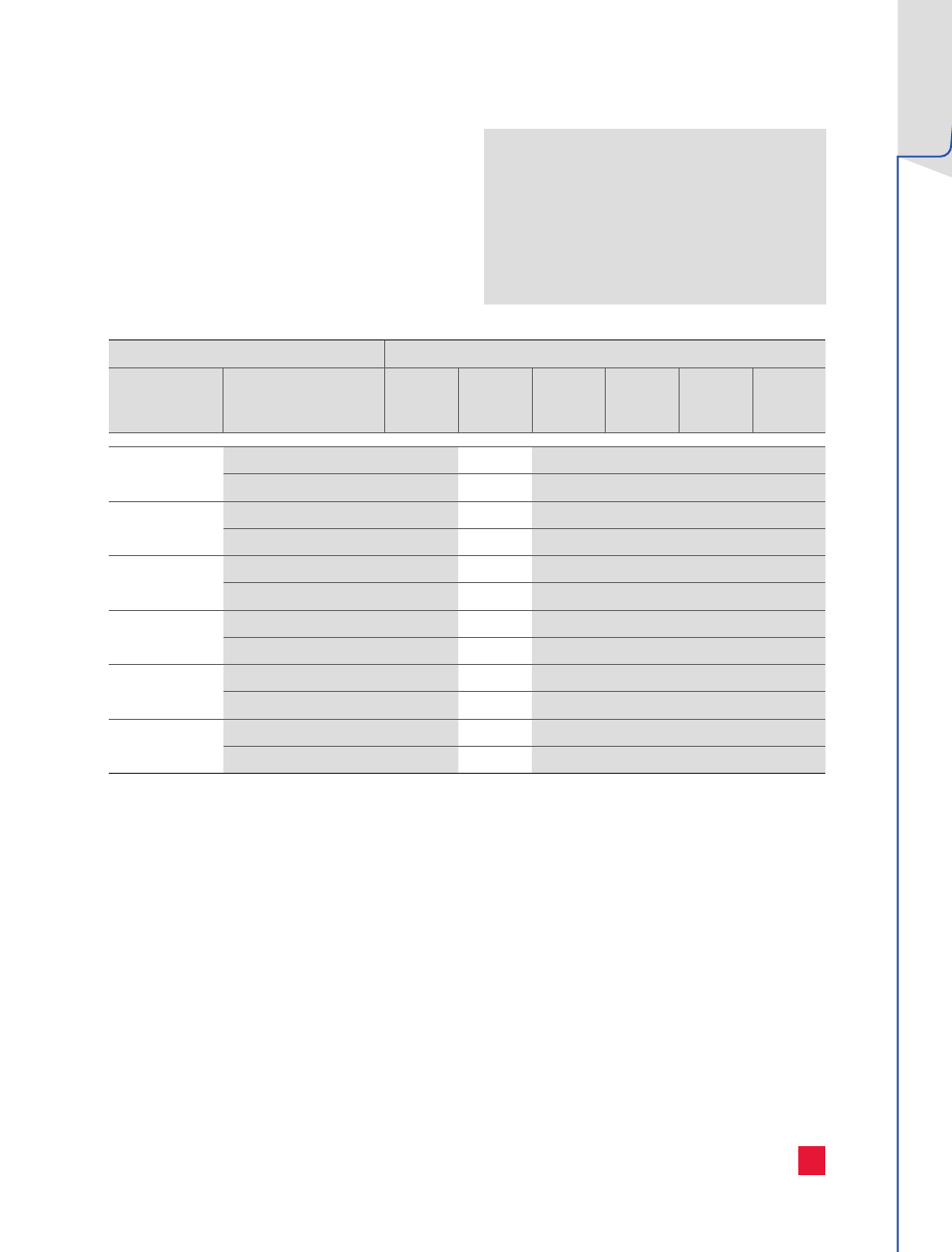

The table further on this page, which has been

derived from the standard DIN 4140, indicates the

initial risks of electrochemical corrosion in cases

where various combinations of metals are used.

Note

The table does not take into account forms

of corrosion with other root causes, such as

stress corrosion. For further information, see

Chapter 2.2 “Product properties & test

methods” – AS-Quality on page 115.

Material

Combination material

Metal

Surface ratio in proportion to

combination material

Zinc

Aluminum

Ferritic

steel

Lead

Austenitic

stainless

steel

Copper

Zinc

Small

-

M

M

H

H

H

Large

-

L

L

L

L

L

Aluminum

Small

L

-

L

H

H

H

Large

L

-

L

M

L

H

Ferritic steel

Small

L

L

-

H

H

L

Large

L

L

-

L

L

L

Lead

Small

L

L

L

-

H

H

Large

L

L

L

-

M

M

Austenitic stainless

steel

Small

L

L

L

L

-

M

Large

L

L

L

L

-

L

Copper

Small

L

L

L

L

L

-

Large

L

L

L

L

L

-

L - Light or little corrosion to material

M - Moderate corrosion to material, for example, in very humid atmospheres

H - Heavy electrochemical corrosion to material

Observation: The table shows the corrosion of the “material”, and not that of the “combination material”.

“Light” means: “small-scale in proportion to the combination material”, “heavy” means: “large-scale in

proportion to the combination material”.

Example 1: Material is a zinc galvanized screw in combination material, a cladding made from austenitic

stainless steel: Row “zinc small”: “H” – heavy corrosion of the screw.

Example 2: Material , a cladding made from austenitic stainless steel screwed on with a screw galvanized

with combination material zinc: Row “austenitic stainless steel large”. “L” – the corrosive attack upon the

austenitic steel is light.

Electrochemical Corrosion Potential

21