1 norms & standards, 2 insulation specification o) british standard – Roxul Industrial Insulation Process User Manual

Page 101

2.1 Norms & Standards

2.1.2 Insulation specification

o) British standard

British Standards are produced by BSI British

Standards, a division of BSI Group that is

incorporated under a Royal Charter and is

formally designated as the National Standards

Body (NSB) for the UK. The standards produced

are titled British Standard XXXX[-P]:YYYY where

XXXX is the number of the standard, P is the

number of the part of the standard (where the

standard is split into multiple parts) and YYYY is

the year in which the standard came into effect.

British Standards currently has over 27,000 active

standards.

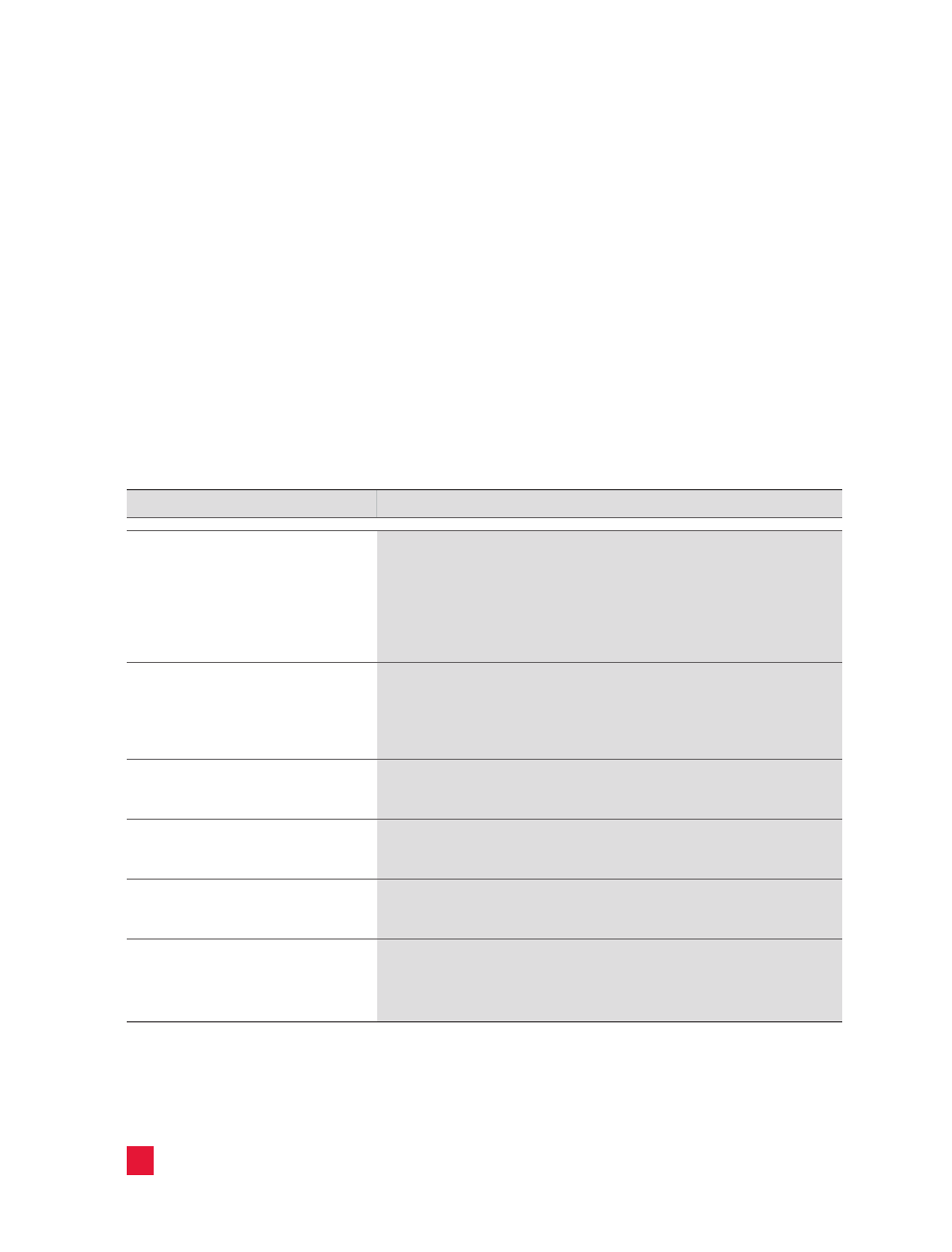

The following table provides an overview of the

standards and regulations that must be taken

observed when insulating industrial plants with

ProRox

®

insulation. On the one hand, they are

grouped according to product and material

standards, which establish the different insulation

properties, and on the other hand, according to

validation and design rules.

Standard

Description

BS 5970: Code of practice for thermal insulation of

pipework and equipment in the temperature range of

-148 °F (-100 °C) to +1600 °F (+870 °C)

This British Standard code of practice describes aspects of thermal insulation for pipework and equipment

in the temperature range -148 °F (-100 °C) to +1600 °F (+870 °C). The installation techniques described in

this standard can be used outside the temperature range indicated, however, it is recommended that for such

applications specialist advice is sought.

This standard explains the basic principles that should be followed in selecting insulating systems for specific

requirements.

BS 5422: Method for specifying thermal insulating

materials for pipes, tanks, vessels, ductwork and

equipment operating within the temperature range

-40 °F (-40 °C) to +1300 °F (+700 °C)

This British Standard describes a method for specifying requirements for thermal insulating materials on

pipes, tanks, vessels, ductwork and equipment for certain defined applications and conditions within the

temperature range -40 °F (-40 °C) to +1300 °F (+700 °C). It gives the recommended thickness and required

performance of thermal insulation material for various applications.

BS 1710 Specification for identification of pipelines and

services

Colours for identifying pipes conveying fluids in liquid or gaseous condition in land installations and on board

ships. Colour specifications in accordance with BS 4800.

BS 3958-Part 4: Thermal insulating materials. Bonded

preformed man-made mineral fiber pipe sections

Physical and chemical requirements, dimensions and finishes for pipe sections generally for use at elevated

temperatures.”

BS 3958-Part 3: Thermal insulating materials. Metal

mesh faced man-made mineral fiber mattresses

Specifies composition, moisture content, physical and chemical requirements for mineral fiber mattresses,

faced on one or both sides with flexible metal mesh.

BS 3958-Part 5: Thermal insulating materials.

Specification for bonded man-made mineral fiber boards

(slabs)

Composition, moisture content, physical and chemical requirements, and standard sizes.

Products are divided into four groups according to thermal conductivity and temperature range.

98