Roxul Industrial Insulation Process User Manual

Page 2

Contents

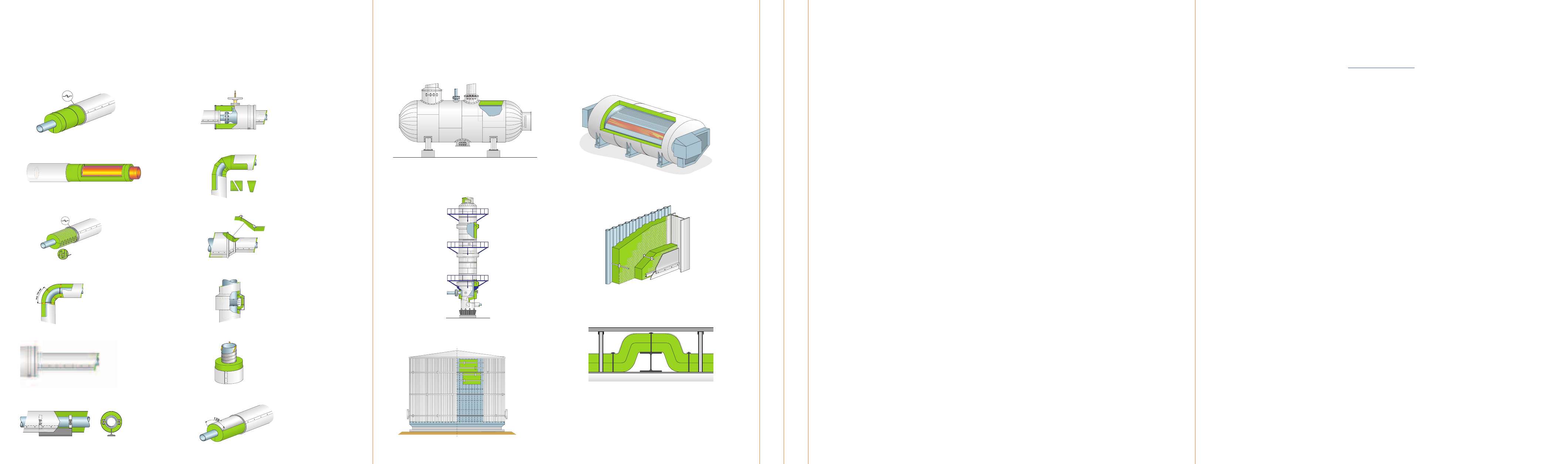

1. System solutions

7

1.1 Planning and preparation

11

1.2 Insulation of piping

23

1.3 Insulation of vessels

47

1.4 Insulation of columns

53

1.5 Insulation of storage tanks

59

1.6 Insulation of boilers

67

1.7 Insulation of flue gas ducts

75

1.8 Cold boxes

82

2. Theory

85

2.1 Norms & Standards

88

2.2 Product properties & test methods

107

2.3 Bases for thermal calculations

120

3. Tables

127

3.1 Units, conversion factors and tables

130

3.2 Product properties insulation and cladding materials

146

3.3 Usage tables

149

4. Products

169

ProRox

®

PS 960

NA

171

ProRox

®

PS 980

NA

ENERWRAP

®

MA 960

NA

ProRox

®

SL 920

NA

ProRox

®

SL 930

NA

ProRox

®

SL 940

NA

ProRox

®

SL 960

NA

ProRox

®

SL 540

NA

ProRox

®

SL 560

NA

ProRox

®

SL 590

NA

ProRox

®

SL 430

NA

ProRox

®

SL 450

NA

ProRox

®

SL 460

NA

ProRox

®

SL 760

NA

ProRox

®

FSL 920

NA

ProRox

®

FSL 930

NA

ProRox

®

FSL 940

NA

ProRox

®

FSL 960

NA

ProRox

®

MA 930

NA

ProRox

®

MA 940

NA

ProRox

®

GR 903

ProRox

®

LF 970

ProRox

®

Rocktight

Overview: ROXUL

®

Industrial Insulation Solutions

1.2.1 Insulation with pipe sections

29

1.6.1 Insulation of fire tube boilers

67

1.6.2 Supercritical steam generators

69

1.2.7 Insulation of valves and flanges

40

1.2.8 Insulation of pipe elbows and T pieces 42

1.2.9 Reducers

43

1.2.10 Expansion joints

44

1.2.11 Tracing

45

1.2.12 Foot traffic

46

1.2 Insulation of piping

23

1.6 Insulation of boilers

67

1.4 Insulation of columns

53

1.5 Insulation of storage tanks 59

1.7 Insulation of flue gas ducts 75

1.8 Cold boxes

82

1.3 Insulation of vessels

47

1.2.2 Insulation with pipe wraps (mats)

31

1.2.3 Insulation with wired mats

33

1.2.4 Insulation support

34

1.2.5 Cladding

36

1.2.6 Pipe hangers and pipe support

39