2 cladding materials – Roxul Industrial Insulation Process User Manual

Page 151

3.2 Product properties insulation and cladding materials

3.2.2 Cladding materials

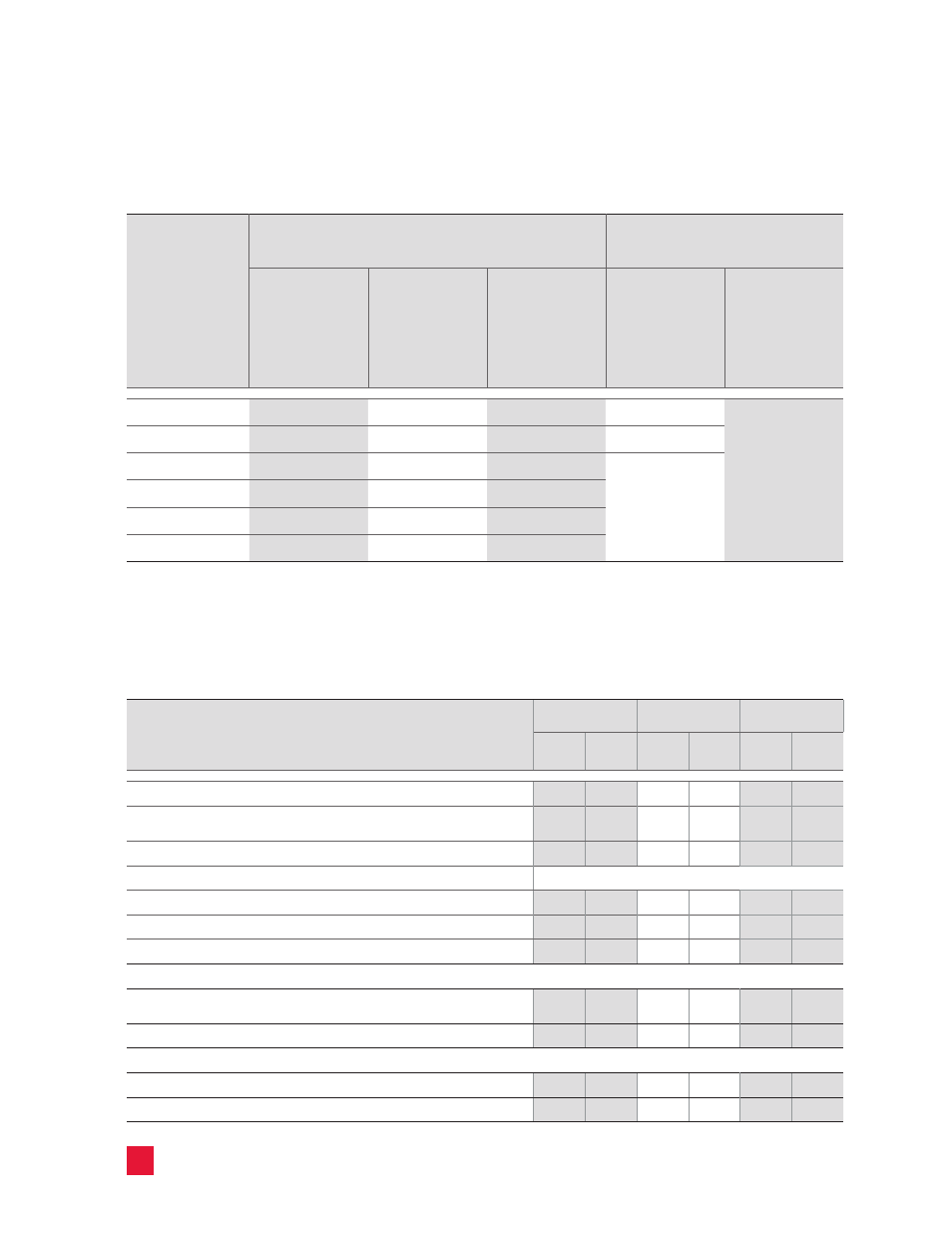

3.2.2.4 Thickness metal cladding in accordance with DIN 4140

3.2.2.5 Thickness of metal cladding in accordance with BS 5970

External diameter

insulation (mm)

Minimum sheet thickness

Overlap

Galvanized.

Aluminized.

Alu-zinc and

painted steel

Stainless steel

E DIN EN 10028-7 and

DIN EN 10088-3

Aluminum

Longitudinal joint

Circumferential joint

up to 400

0.5

0.5

0.6

30

50

400 to 800

0.6

0.5

0.8

40

800 to 1200

0.7

0.6

0.8

50

1200 to 2000

0.8

0.6

1.0

2000 to 6000

1.0

0.8

1.0

> 6000

1.0

0.8

1.2

Type of area

Protected mild steel

Aluminum

Stainless steel

Flat

mm

Profiled

mm

Flat

mm

Profiled

mm

Flat

mm

Profiled

mm

Large flat areas over flexible insulation

1.2

0.8

1.6

0.9

1.0

0.6

Smaller flat areas over flexible insulation, or large areas over pre-formed boards/slabs

(including large curved surfaces)

1.0

0.8

1.2

0.9

0.8

0.5

Removable insulated manhole and door covers

1.6

-

1.6

-

1.0

-

Flange and valve boxes

As metal on adjacent pipe

Pipes with an insulated diameter of more than 450 mm

1.0

-

1.2

-

0.8

-

Pipes with an insulated diameter of 150 mm to 450 mm

0.8

-

0.9

-

0.6

-

Pipes with an insulated diameter of less than 150 mm

a

0.6

-

0.7

-

0.5

-

Recommended thickness for reinforcing plates and where foot traffic is likely

For flat surfaces, large curved areas and pipes with an insulated diameter of 450 mm or more

1.6

-

1.6

-

1.0

-

For pipes with an insulated diameter of less than 450 mm

1.0

-

1.2

-

0.8

-

Recommended thickness where no mechanical damage is likely

For pipes with an insulated diameter of less than 1000 mm

0.3

-

0.3

-

0.3

-

For pipes with an insulated diameter of more than 1000 mm

0.4

-

0.4

-

0.4

-

a

Smaller sheet thicknesses are also possible in consultation with the customer.

b

With regard to pipes, the circumferential joint overlap can be omitted if the circumferential joints are joined by swage and counter swage.

In the case of cladding with a large surface area and high wind loads, structural verifications may be required. In that instance, only those

binding agents permitted by the building authorities may be used. The DIN 1055-4 applies in respect of the loading assumptions.

a

For insulation diameters of 150 mm or less, the thickness of reeded aluminum should be not less than 0.25 mm.

For insulation diameters in excess of 150 mm, it should be 0.4 mm or greater.

148