Tables, 3 usage tables, Usage t abl es – Roxul Industrial Insulation Process User Manual

Page 152

Usage t

abl

es

3. Tables

3.3 Usage tables

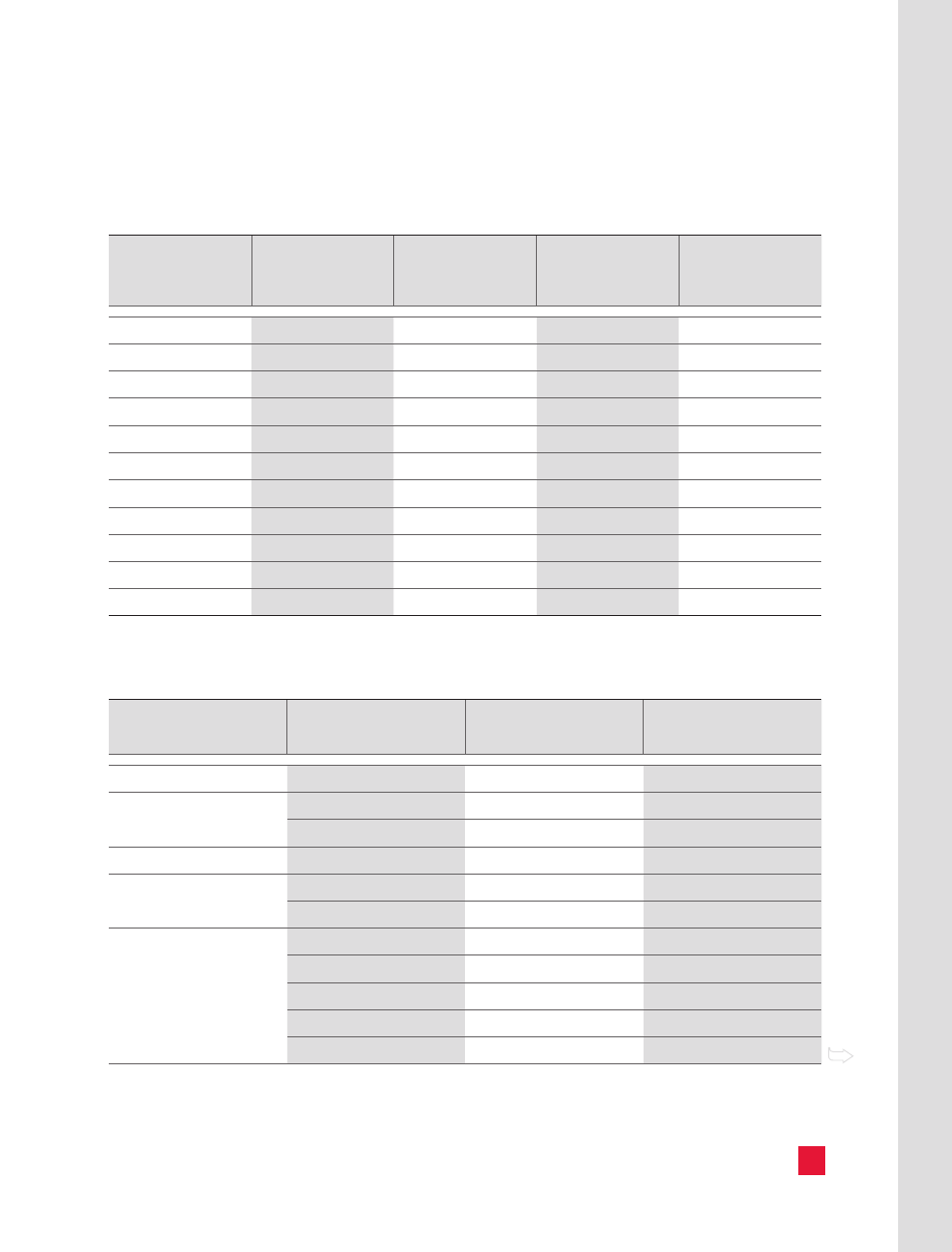

3.3.1 Construction materials

3.3.2 Fluids which are commonly used in process industry

Material

Density lb / ft

3

Thermal conductivity

BTU.in / (ft

2

.hr.°F) at 75 °F

Specific heat capacity

BTU / (lb °F)

Linear expansion

coefficient 10

-6

R

-1

Aluminum

169

1532

0.220

13.33

Concrete

150

14.6

0.22 - 0.26

6.16 - 6.72

Bitumen (Solid)

66

1.18

0.41 - 0.46

112

Bronze, red brass

512

423

0.088

9.8

Cast iron

490 - 443

291 - 437

0.129

5.82

Wrought (cast) iron

487

465

0.110

6.55

Copper

559

2725

0.096

9.24

Wet soil

100 - 125

8.3 - 20.8

0.478

-

Dry soil

87 - 100

2.8 - 4.2

0.201

-

Stainless steel

481 - 506

69 - 319

0.119

8.96

Iron

490

319 - 361

0.115

6.16

Group

Material

Density lb/ft

3

Specific heat capacity

BTU/(lb F) at 70 °F

General

Water

62.5

1.001

Alcohols

Ethanol

44.5

0.559

Methanol

49.5

0.596

Food

Beer

64

0.900

Milk

Milk

64

0.941

Olive oil

57.5

0.471

Fuels

Petrol

38.5 to 49

0.482

Diesel

52

0.461

Fuel oil (HEL)

53

0.449

Fuel oil (HS)

61

0.411

Petroleum

49

0.525

149