2 insulation of piping, Comparison of the different insulation systems – Roxul Industrial Insulation Process User Manual

Page 29

1.2 Insulation of piping

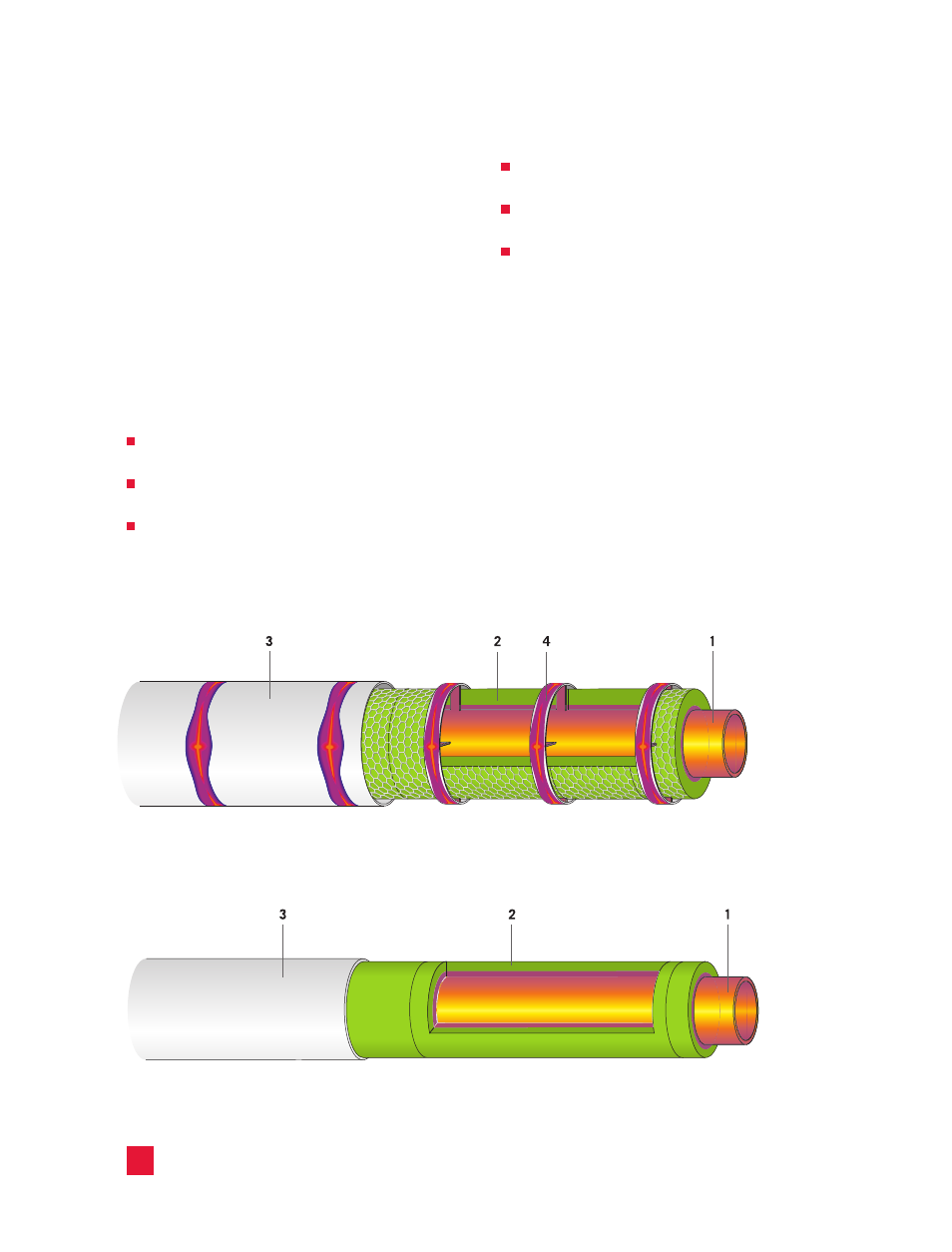

1. Pipe - 2. Insulation: ProRox

®

Pipe Sections or Pipe Wraps (Mats): ENERWRAP

®

MA 960

NA

- 3. Cladding

1. Pipe - 2. Insulation: ProRox

®

Wired Mats - 3. Cladding - 4. Spacer ring

Insulation system with a spacer ring

Insulation system without a spacer ring

Comparison of the different insulation

systems

The particular advantage of pipe sections and pipe

wraps (mats) lies in the fact that support

structures are not required and therefore thermal

bridges caused by the insulation are minimized or

removed. On the other hand, wired mat systems

have their advantages due to their ability to be

structurally sound when insulating around

irregularly shaped pipe sections.

The advantages of pipe sections and load-bearing

pipe wraps (mats) at a glance are:

It is not necessary to install spacers or support

structures.

Faster application without the interference of

spacers.

Both products offer an even, firm surface for

installing the sheet cladding.

The lack of spacers gives rise to lower heat

losses.

It yields an even surface temperature across

the sheet cladding.

In comparison to wired mats, a more shallow

insulation thickness can be applied. The operating

costs of the installation decrease as a result of

lower heat loss.

Generally speaking, a spacer or support structure

functions as a thermal bridge, as a result of which

the heat loss in the total insulation is increased

considerably.

26