2 product properties & test methods – Roxul Industrial Insulation Process User Manual

Page 117

2.2 Product properties & test methods

2.2.3 Maximum service temperature

Application of maximum service

temperature

The practical application of the test methods

varies by country and plant owner. In case of

special conditions, where the insulation is

permanently exposed to high dynamic loads and

temperatures (e.g. Power Plants), a considered

insulation selection is required as it cannot be

included within the measurements. This can be

done based on expert judgement or by using the

reduction factors (fa) as defined in the German

Standard AGI Q101 “Insulation works on power

plant components”. The calculated service

temperature is generally below the maximum

service temperature.

When selecting a suitable insulation material in

terms of the maximum service temperature, the

external influences affecting the insulation system

must be considered, for example:

Static loads (e.g. cladding)

Dynamic loads (e.g. oscillations)

Type of construction (with or without a spacer).

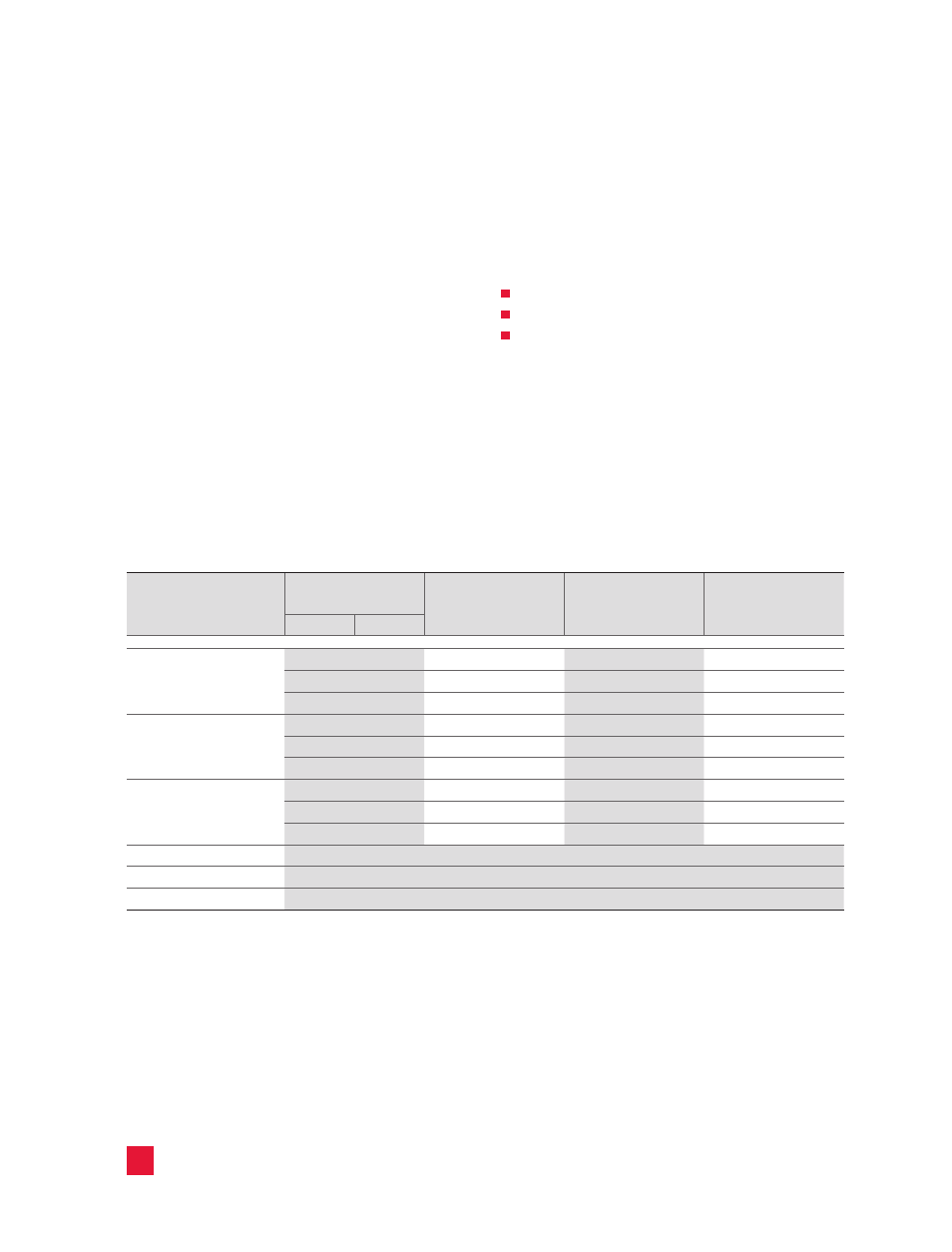

The table shown on the following page, showing

general reduction ratios f

a

for determining the

working temperature, is taken from AGI Q101.

In this respect, the maximum service temperature

should be multiplied by f

a

.

Reduction ration (f

a

)

Maximum service

temperature

With spacer and support

construction

Without spacer and support

construction

With spacer and support

construction + air space

(°F)

(°C)

Pipes ≤ NPS 20

(DN 500)

752

400

1.0

0.9

0.9

1076

580

0.9

0.9

0.9

1310

710

0.9

0.8

0.8

Pipes ≥ NPS 20

(DN 500)

752

400

0.9

0.8

0.9

1076

580

0.9

0.8

0.9

1310

710

0.9

0.8

0.9

Flue gas ducts, hot air ducts,

steel chimneys, vessels,

gas turbine ducts

752

400

0.9

0.8

0.9

1076

580

0.9

0.8

0.9

1310

710

0.9

0.8

0.8

Boiler walls

0.8

Within range of boiler roof

0.9

Dead spaces

0.8

Reduction ratio (f

a

) for determining the working temperature

114