RKI Instruments Gas Tracer 10,000 ppm User Manual

Page 91

10,000 ppm Gas Tracer Operator’s Manual

Troubleshooting • 84

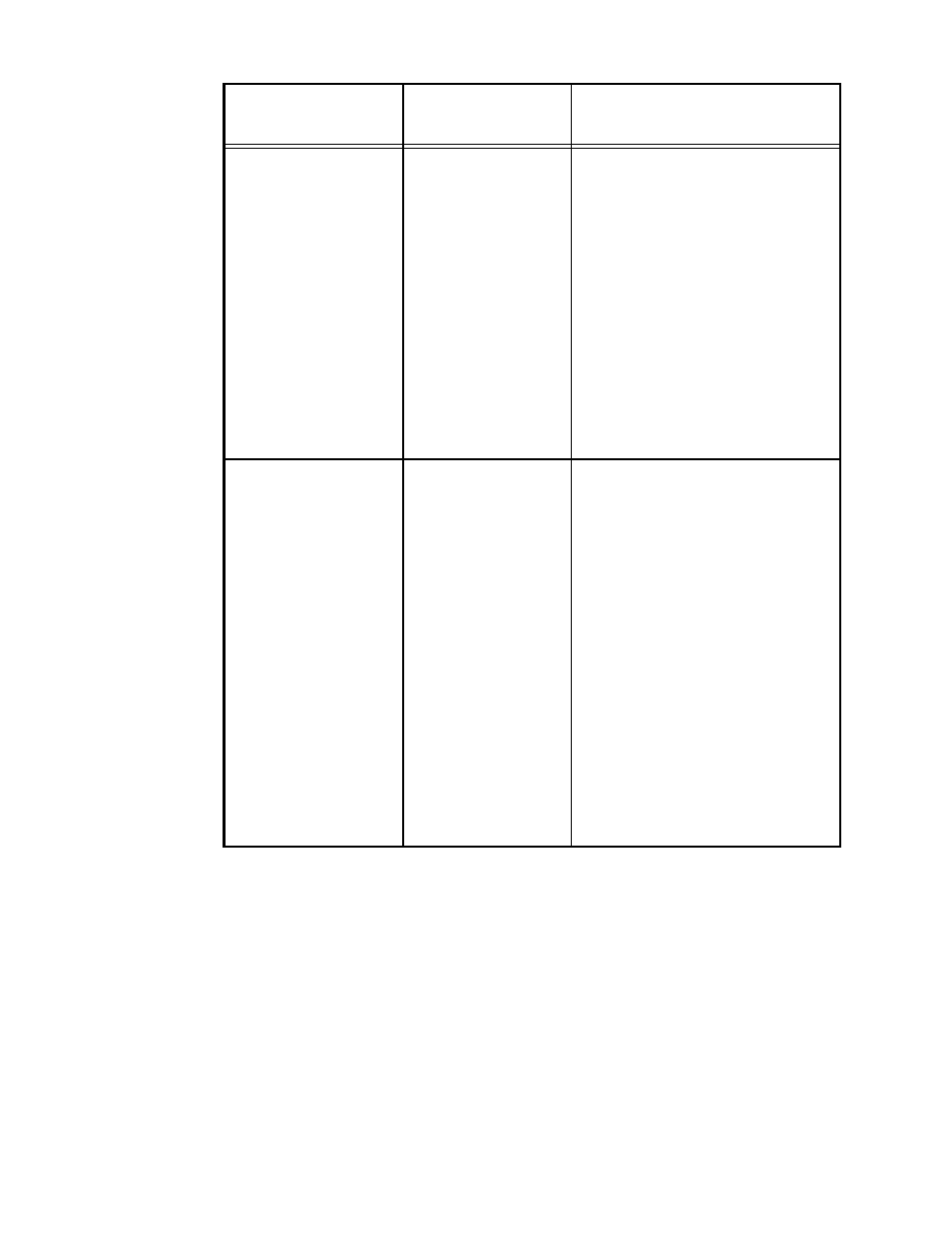

• The unit indicates

flow failure and

does not recover

when RESET

SILENCE is

pressed and

released.

• The cotton filter

in the probe or

filter holder is

dirty and

clogged.

• The sample hose

has a kink or

obstruction.

• The hydrophobic

filter disks or wire

mesh disk are

dirty and

clogged.

• The pump is

malfunctioning.

1. Change the cotton filter in the

probe or filter holder.

2. Inspect the sample hose for

kinks or obstructions and

replace if necessary.

3. Inspect the hydrophobic filter

disks and the wire mesh disk

and replace if necessary.

4. Perform a low flow setpoint

adjustment. For instructions,

see “Performing a Low Flow

Setpoint Adjustment” on

page 80.

5. If difficulties continue, contact

RKI Instruments for further

instruction.

• Auto calibration

fails or unable to

set the response

readings during

single calibration.

• The auto

calibration value

may not match

the cylinder gas

concentration

(auto calibration

only).

• The sample gas

is not reaching

the sensor

because of a bad

connection.

• The calibration

cylinder may be

out of gas or is

outdated.

• The ppm sensor

may need

replacement.

1. Check all calibration tubing for

leaks or for any bad

connections.

2. Make sure the Gas Tracer

has been properly set up for

calibration.

3. Verify that the calibration

cylinder contains an adequate

supply of sample.

4. If the fail condition continues,

replace the ppm sensor.

5. If the difficulties continue,

contact RKI Instruments, Inc.

for further instruction.

Table 5: Troubleshooting the Gas Tracer

Symptoms

Probable

Causes

Recommended Action