7cutting height, 1adjusting gauge roller height, Cutting height – MacDon R85 Rotary Disc 16 Foot Self-Propelled Windrower Headers User Manual

Page 87: Adjusting gauge roller height, Danger, 7 cutting height

6.7 Cutting Height

Cutting height is determined by a combination of the angle of the cutterbar/header and the roller gauge or skid

shoe settings.

Cutting height should be adjusted for optimum cutting performance without allowing excessive build-up of mud and

soil inside the header that can lead to poor crop flow and increased wear on cutting components.

Choose an angle that maximizes performance for your crop and field conditions. Refer to Section

Optional adjustable gauge rollers or skid shoes are available to also provide different cutting heights. Refer to

Sections

6.7.1 Adjusting Gauge Roller Height , page 79

and

6.7.2 Adjusting the Skid Shoe Height, page 80

.

• Lowering the skid shoes/gauge rollers or decreasing header angle increases the cutting height. This may be

desirable in stony conditions to reduce damage to cutting components. Also, a longer stubble length helps material

dry faster.

• Raising the skid shoes/gauge rollers and increasing header angle allows the crop to be cut lower.

To minimize damage to cutterbar components, scooping soil, or soil build-up at the cutterbar in damp conditions,

header float should be set as light as possible without causing excessive bouncing.

When the float setting is light, it may be necessary to use a slower ground speed to avoid excessive bouncing and

leaving a ragged cut.

6.7.1 Adjusting Gauge Roller Height

DANGER

To avoid bodily injury or death from unexpected

start-up or fall of raised machine: stop engine,

remove key, and engage safety props before going

under machine for any reason.

1. Raise header fully, stop engine, and remove key.

Engage header safety props.

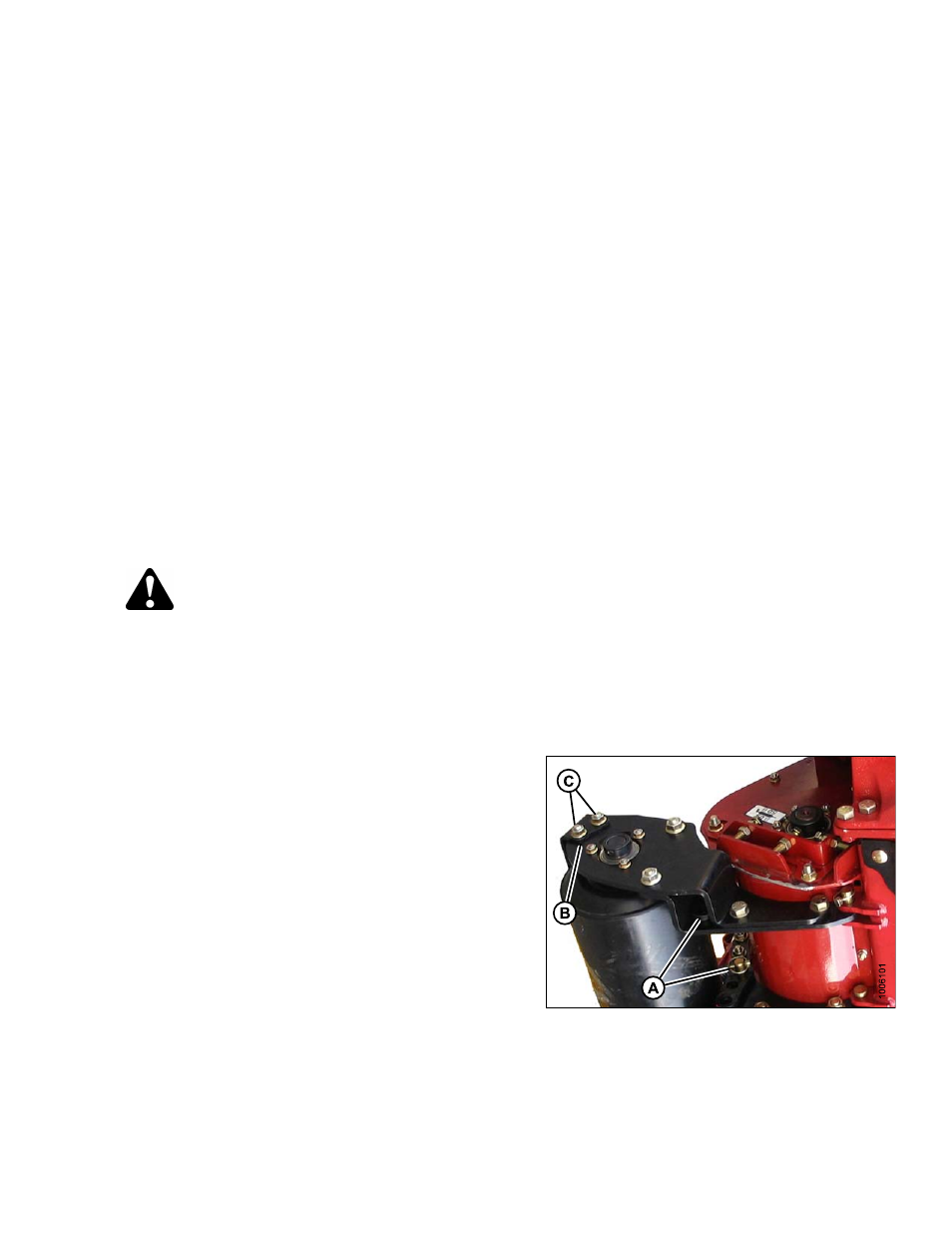

2. Remove lynch pin and remove adjuster pin (A) from

one side of the roller.

3. Hold roller and remove lynch pin and adjuster pin (A)

from other side. Position roller at desired position and

reinstall adjuster pins (A). Secure with lynch pins.

4. Repeat for roller at opposite end of header.

5. Adjust mud bar (B) by loosening nuts (C) and retighten

to maintain minimum clearance between mud bar

and roller.

Figure 6.18

169457

79

Rev. F